Reviewed by Lexie CornerApr 25 2024

Dr. Han Joong Tark and student researcher Lee Do Geun at Korea Electrotechnology Research Institute's Nano Hybrid Technology Research Center have devised a novel manufacturing method for "silicon/nitrogen-doped carbon composite anode materials," designed to boost the capacity and stability of lithium-ion battery anodes. The study was published in the journal Advanced Functional Materials.

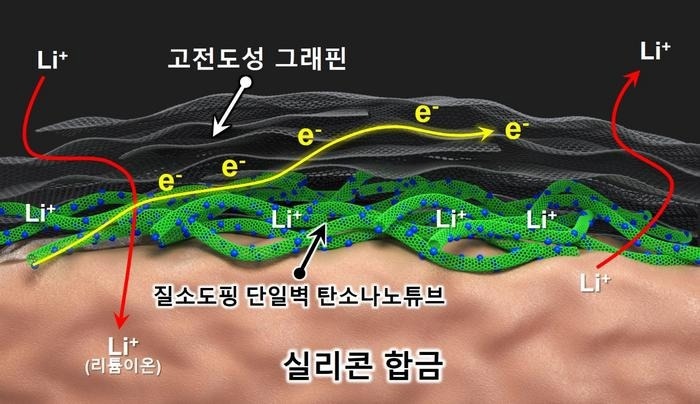

Development of Si alloy/nanocarbon composite anode materials that overcome the limitations of silicon using “nitrogen-doped carbon nanotubes” and “graphene” by KERI. Image Credit: Korea Electrotechnology Research Institute

Development of Si alloy/nanocarbon composite anode materials that overcome the limitations of silicon using “nitrogen-doped carbon nanotubes” and “graphene” by KERI. Image Credit: Korea Electrotechnology Research Institute

While silicon presents a notably higher energy density than graphite, a prevalent anode material, it faces a notable limitation: swelling by 3-4 times during charge and discharge cycles, resulting in performance decline. Researchers are mitigating this challenge by blending silicon with graphite to harmonize their respective advantages and drawbacks.

KERI has provided nitrogen-doped single-walled carbon nanotubes and graphene to optimize silicon content and circumvent its constraints. As a result of their tiny diameter and superior conductivity over their multi-walled counterparts, single-walled carbon nanotubes pose dispersion problems. By utilizing their knowledge of nanocarbon materials, KERI has created novel functionalization and colloidal dispersion techniques that make it easier to add nitrogen to the surface of carbon nanotubes.

These nitrogen-doped single-walled carbon nanotubes accelerate the movement of lithium ions toward silicon when applied to lithium-ion battery anodes, improving charging stability and speed over multiple cycles of charge and discharge. Silicon expansion is further stabilized by encasing the anode materials in graphene.

Through extensive testing, KERI has shown that batteries made with its composite anode materials continue to function at a rate of over 82 % after 100 cycles of charge and discharge. In comparison, traditional silicon composite anodes only maintain a performance of 30 %. Thanks to this development, traditional conductive additives like carbon black are no longer necessary.

The group realizes larger uses for this technology, such as solid-state batteries, where the rate at which lithium diffuses is crucial.

KERI anticipates significant interest from businesses looking to purchase high-capacity lithium-ion batteries, so it has finished full-cell evaluations and filed patent applications for its composite anode materials. Thus, it is in a good position to find possible technology transfer partners.

Journal Reference:

Lee, G. D., et al. (2024) Dispersant-Free Colloidal and Interfacial Engineering of Si-Nanocarbon Hybrid Anode Materials for High-Performance Li-Ion Batteries. Advanced Functional Materials. doi.org/10.1002/adfm.202311353