DELO has introduced a new microdispensing valve. The DELO-DOT PN5 LV pneumatic jet valve is designed for dispensing low-viscosity adhesives and other media in miniaturized applications. Thanks to its compact design, it also requires very little space to install in production systems.

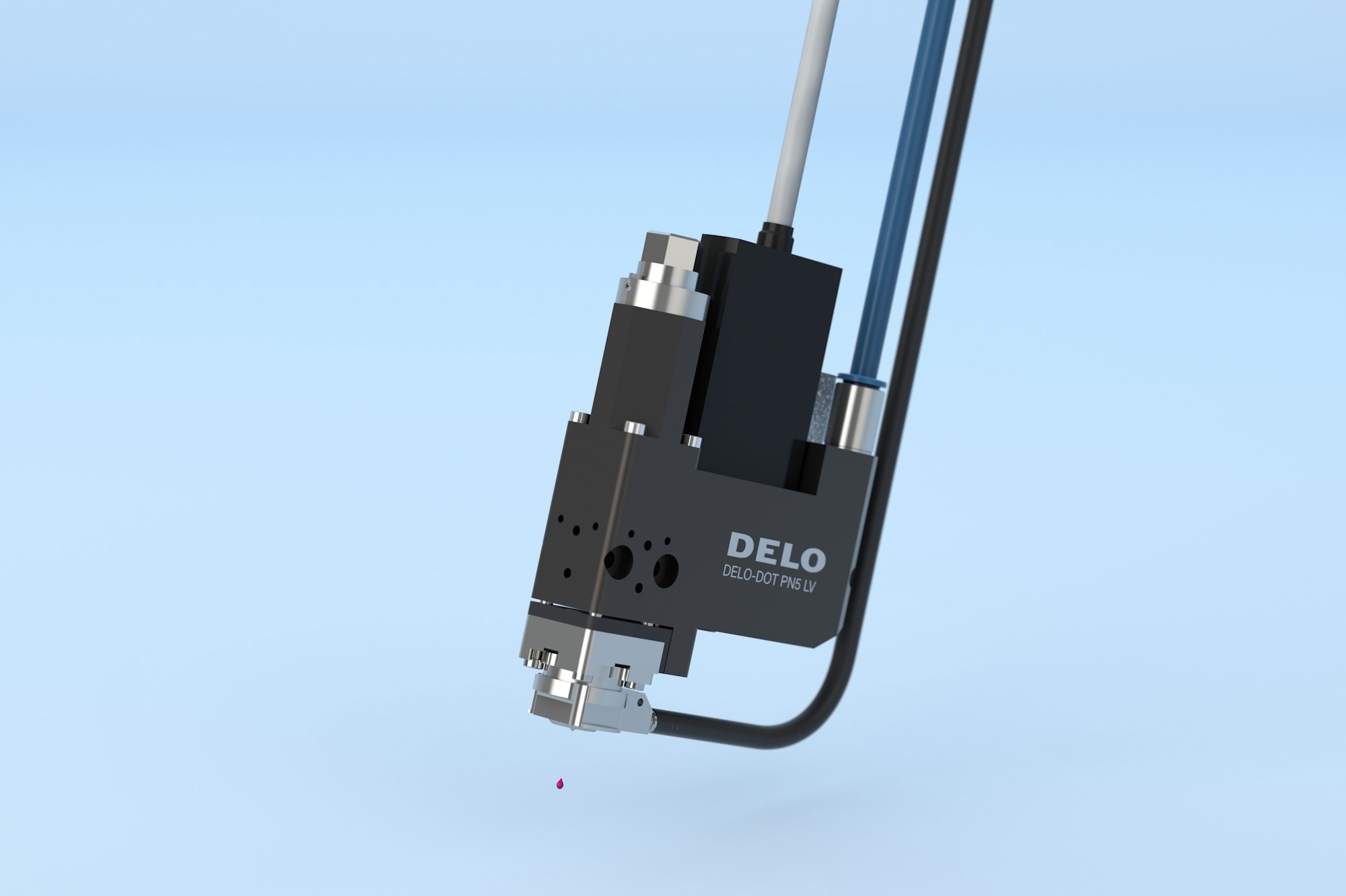

Particularly suitable for low-viscosity media and very small quantities (small drop of adhesive illustrated in magenta): DELO-DOT PN5 LV. Image Credit: DELO

Particularly suitable for low-viscosity media and very small quantities (small drop of adhesive illustrated in magenta): DELO-DOT PN5 LV. Image Credit: DELO

This new device widens DELO's existing portfolio of dispensing valves. While the closely related DELO-DOT PN5, introduced in 2022, was developed for more viscous, highly filled materials, the new LV (low-viscosity) variant is primarily aimed at dispensing smaller droplet sizes of low-to-medium-viscosity media with up to 35,000 mPa·s.

Interchangeable nozzles with different diameters and a flexible, adjustable plunger stroke ensure precise and reliable applications at different droplet sizes. Volumes of as low as 1 nl can be achieved, which corresponds to droplet diameters of 250 µm or less.

Thanks to its compact dimensions of 68 mm × 19 mm × 90 mm (W x D x H), DELO-DOT PN5 LV requires very little space to install in production systems. At just 240 g, its lightweight construction enables quick valve acceleration as well as a smaller axis and drive design. It also supports high-speed processes with a continuous dispensing frequency of up to 250 Hz.

The drive found in DELO-DOT PN5 LV is designed to be operated over one billion cycles, meeting the highest standards of robustness. The fluid plunger is composed of durable materials such as ceramic and carbide. Thanks to its two-part construction, users can replace both the plunger itself and the nozzle in the event of wear, namely at the end of the life cycle. The bayonet lock allows for simple removal without any tools. Cleaning the fluid system can also be done with minimal effort.

In contrast to needle dispensers, jet valves apply the adhesive in a contactless way that prevents the valve and component from colliding. This is particularly advantageous for complex dispensing geometries. As no movement in the z-direction is required, adhesive jetting also enables higher dispensing speeds.