Reviewed by Lexie CornerAug 27 2024

Researchers from the University of Sharjah have created “UF membranes with superior water flux and rejection rates” that can solve critical inefficiencies in existing water treatment technologies. This study was published in the Journal of Membrane Science.

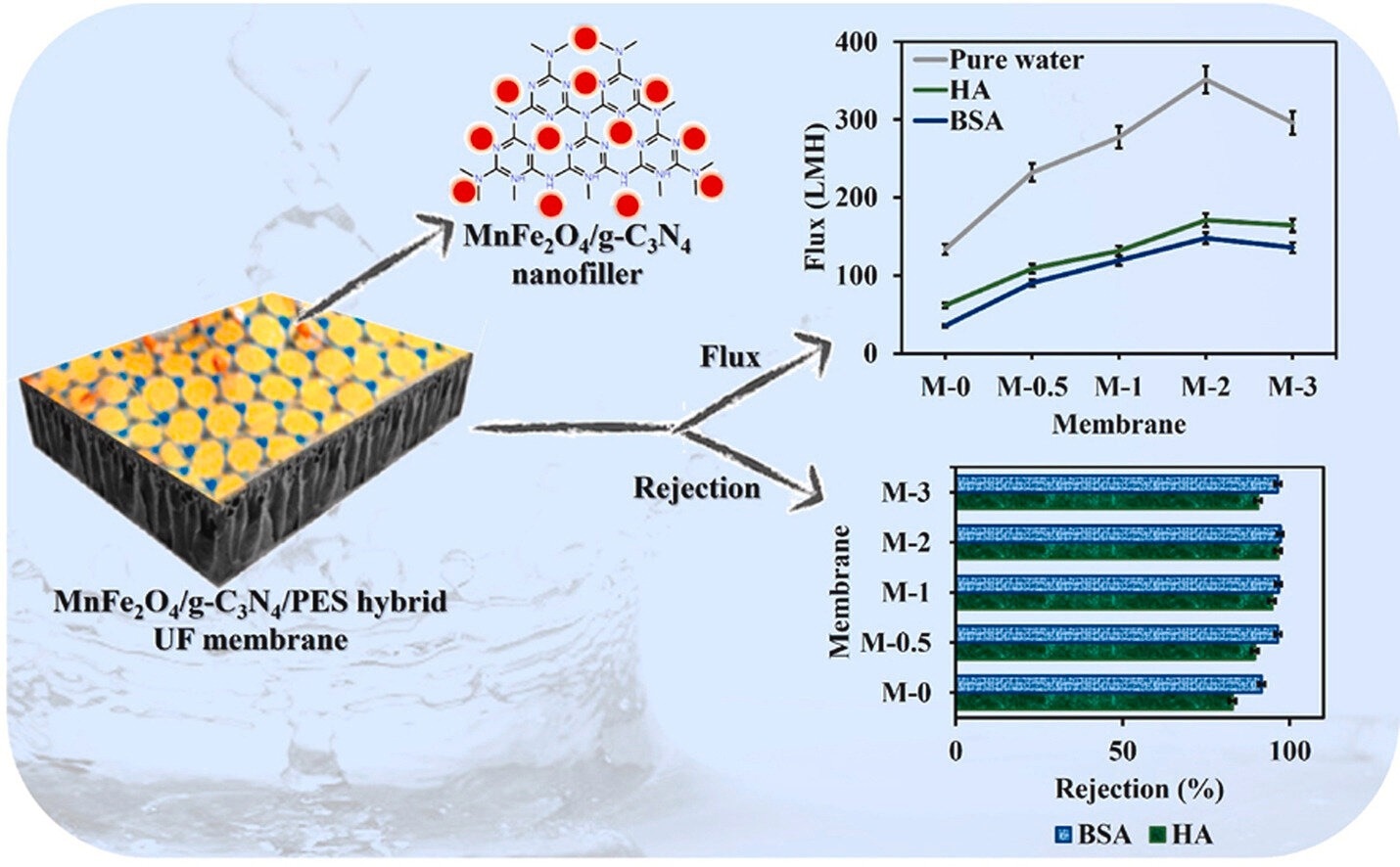

Image Credit: Journal of Membrane Science (2024). DOI: 10.1016/j.memsci.2023.122259

Scientists believe that incorporating manganese ferrite nanoparticles into the filtering sheets used in water treatment facilities could significantly enhance the global drinking water supply.

Our study records some extraordinary results. The top-performing membrane, containing 2 wt.% composite material, achieved a water flux of 351.4 LMH, which is 2.6-fold higher than the pristine PES membranes.

Dr. Ismail Almanassra, Study Co-Author and Research Associate, Institute for Science and Engineering, University of Sharjah

Polyethersulfone (PES) membranes are crucial in water treatment facilities. They act as barriers, allowing clean water to pass through while blocking undesired contaminants. These membranes effectively remove salts, pollutants, and other impurities from the water, making it safe for consumption.

“The significance of this project lies in its potential to revolutionize water treatment processes, offering technological, economic, environmental, and health benefits on a broad scale,” Dr. Almanassra added.

He stated, “The project effectively mitigates biofouling, reducing maintenance and operational costs while contributing to environmental sustainability through more efficient water management.”

Ultrafiltration (UF) membranes are extensively used in water treatment plants worldwide, as well as in desalination projects, groundwater pretreatment, food processing, industrial chemical separation, and wastewater treatment.

UF membranes serve as barriers, filtering out endotoxins, viruses, and other materials and pathogens, thereby producing potable water with high purity and low silt density. These membranes are primarily made from polymeric materials or ceramics.

Dr. Almanassra highlighted that water treatment and desalination facilities are currently facing various challenges, particularly during the pretreatment stage, where polymer-based UF membranes are used for decontamination.

He added, “One major issue is biofouling, where biological materials accumulate on the membrane surface, negatively impacting permeate flux and water quality.”

Biofouling is a significant issue that reduces the effectiveness and longevity of ultrafiltration (UF) membranes used in wastewater treatment facilities. Caused by microorganisms, biofouling leads to the pollution and contamination of water, decreases the production of potable water, and results in the covering, blocking, or damaging of membrane surfaces.

To combat this issue, operating engineers typically consider two options: increasing the operating pressure on UF membranes to maintain permeability and water output, or routinely replacing biofouled membranes. However, both strategies result in higher operating and maintenance costs.

The study authors, who come from diverse research backgrounds, have collaborated to develop UF membranes that incorporate hydrophilic elements to combat biofouling more effectively and reduce long-term costs.

“This approach not only enhances permeate flux and contaminant removal rates but also significantly reduces the impact of biofouling over time, leading to more efficient and cost-effective water treatment solutions,” stated Dr. Almanassra.

The researchers' innovation involves modifying 2D graphitic carbon nitride with manganese ferrite nanoparticles to use as nanofillers in PES UF membranes. The membranes were fabricated with varying mass loadings of the additive, ranging from 0.5 to 3 wt.%, using the phase inversion technique.

Before testing and evaluation, these membranes were characterized to assess their morphology, surface roughness, physiochemical, and mechanical properties. They were then tested with fouling agents known to cause biofouling over time, demonstrating the effectiveness of the modified membranes.

“In terms of rejection and anti-fouling capacity, our membrane excelled, rejecting over 95 % of HA and BSA. Impressively, even after hydraulic washing, the membrane maintained a recoverability ratio exceeding 88 %,” Dr. Almanassra stated.

He concluded, “The integration of hydrophilic materials marks a significant advancement in material science, with potential applications beyond water treatment. Ultimately, this project improves public health by providing cleaner, safer water and offers scalable solutions to global water scarcity and pollution challenges.”

Journal Reference:

Jaber, L., et. al. (2024) Pioneering Biofouling Resistant PES UF Membrane with MnFe2O4/g-C3N4 Nanocomposite: Insight into Mechanisms and Fouling Dynamics Journal of Membrane Science. doi.org/10.1016/j.memsci.2023.122259