Reviewed by Danielle Ellis, B.Sc.Oct 1 2024

According to a study in Advanced Functional Materials, Emilio Pérez’s Chemistry of Low-Dimensional Materials group at IMDEA Nanociencia is working with Nanocore, a company, to explore a method of strengthening recyclable plastics.

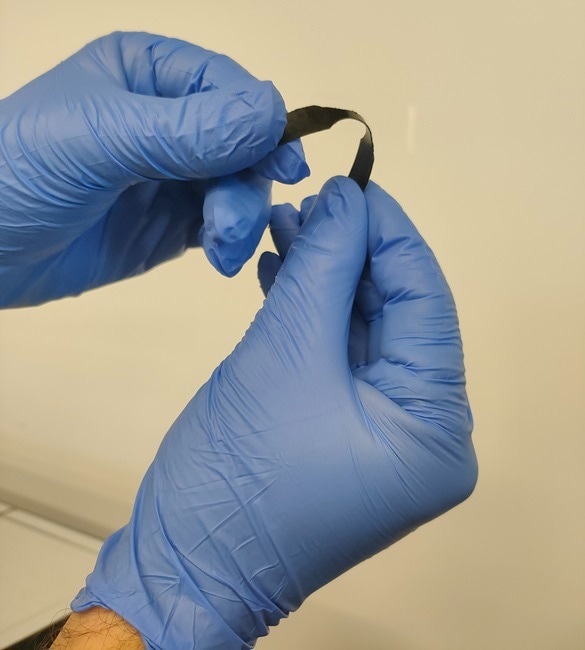

Test tube for mechanical testing. Image Credit: Ion Isasti.

Test tube for mechanical testing. Image Credit: Ion Isasti.

Several ways can be taken to lessen plastics' negative effects on the environment, including recycling and producing stronger plastics. Plastics can be broadly divided into two categories.

First, there are thermoplastics, which can be melted and shaped into different shapes, though repeated melting weakens their mechanical qualities. Furthermore, thermosets, which are composed of polymer chains linked by chemical bonds, are resistant to melting even at elevated temperatures.

When it comes to properties, thermoset plastics are superior to thermoplastics. Despite being brittle, they typically have a greater resistance to impact and mechanical stress. Thermoset plastics, like epoxy resin, silicone, and melamine, are frequently utilized in construction. Engineers use reinforcing materials like carbon fibers to make these polymers stronger.

They are already utilized in the production of extremely durable but difficult-to-recycle items like sports equipment and motorcycle helmets.

The plastic under study is known as a “covalent adaptive network,” and while its molecular structure resembles that of a thermoset plastic, it differs in that it contains covalent bonds between polymer chains that are both strong and reversible. They specifically deal with imines, whose bonds are dynamic and can be rearranged in response to changes in temperature or water.

This study is novel because it uses mechanically interlocked carbon nanotubes, or MINTs, a derivative of carbon nanotubes with a ring molecule surrounding them. The ring molecules and the carbon nanotube are joined mechanically rather than chemically, creating a very strong bond while also permitting some molecule movement along the nanotube.

The researchers equipped the ring with two anchor points (two amines) that formed covalent bonds with the polymers. Thus, the nanotube became a structural component of the polymer network.

Putting Rings on Nanotubes: A Simple and Very Effective Strategy

Carbon nanotubes are simply a sheet of graphene rolled up on itself. Covalent bonds can be used to directly connect a nanotube to other molecules, causing the tube to break slightly, introduce defects, and weaken.

The researchers’ strategy uses a mechanical bond—a ring molecule around the nanotube - to integrate the nanotubes into the polymer lattice, preserving all of their properties while maximizing load transfer from the matrix to the reinforcement. In other words, it was impossible to do better.

The idea is simple: by surrounding the nanotube with a ring, the agglomeration of these fibers, which reduces the effectiveness of the reinforcement, is avoided. In addition, the ring contains polymer interaction sites, which improves stress transfer.

The addition of only 1% nanotubes by weight to the polymer mixture increases Young’s modulus by 77% and tensile strength by 100%. Surprisingly, the mechanical properties of this reinforced plastic remain unchanged after being melted down and recycled up to four times.

This reinforced plastic retains its mechanical properties even after being melted down and recycled up to four times.

According to the Law of Mixtures, which governs engineering, a compound's properties are a mixture of the original materials’ properties based on their relative proportions. The research conducted by the Madrid scientists verifies that this is only true in situations where there is a successful nanoscopic mechanical stress transfer between the two compounds. Thanks to the research team's efforts, the strongest material, nanotubes, has been able to transfer mechanical stress from polymers with maximum efficiency.

With a Young’s modulus of 1TPa, nanotubes are five times more durable than steel despite being substantially lighter. The plastic does not become stronger when more nanotubes are added because they clump together and become less effective. The covalent connection between the polymer and the nanotubes is essential to the outcome.

It All Started with an ERC Grant

The science behind this discovery dates back to 2012, when Emilio Pérez, a researcher, was awarded a prestigious ‘Starting’ grant by the European Research Council (ERC) to explore a novel concept: the attachment of molecular rings to carbon nanotubes.

Pérez consolidated his research group at the IMDEA Nanociencia Institute with this 1.5 million euro grant. They forged mechanical connections between ring molecules and carbon nanotubes for five years, researching the materials’ characteristics but not yet concentrating on potential uses.

Pérez got a call in 2017 from Nanocore ApS, a Danish business that was at the forefront of transferring results to the materials production industry. Additionally, they planned to alter carbon nanotubes using a biochemical method.

They started working on a year-long project together, and later, the experiments were supported by an ERC ‘Proof of Concept’ grant. In 2020, they would enter into a more than three million euro contract to collaborate on the application of carbon nanotubes for plastic reinforcement.

A Myriad of Applications

The investigation into all the most commercially viable reinforced polymers is still ongoing in cooperation with Nanocore. It is a dream come true to produce plastics that can be recycled and melted down to almost equal the strength of carbon fibers. A before and after that will undoubtedly help create a new, sustainable, and environmentally friendly scenario.

Producing lighter structures, such as cars, plans, etc., would mean considerable fuel savings.

Emilio Pérez, Senior Research Professor, IMDEA Nanociencia

Manufacturing with less material and ensuring recyclability presents a promising future.

This research was carried out at IMDEA Nanociencia and is partially supported by the Severo Ochoa Seal of Excellence (CEX2020-001039-S).

Journal Reference:

Isasti, I., et. al. (2024) Reinforcement of Polyimine Covalent Adaptable Networks with Mechanically Interlocked Derivatives of SWNTs. Advanced Functional Materials. doi.org/10.1002/adfm.202408592