A recent article in Scientific Reports detailed the characterization of disordered structures in graphene and monolayer hexagonal boron nitride (hBN) induced by low-energy argon ion irradiation. The study employed automated scanning transmission electron microscopy (STEM) imaging coupled with convolutional neural network-based analysis to examine these structural changes.

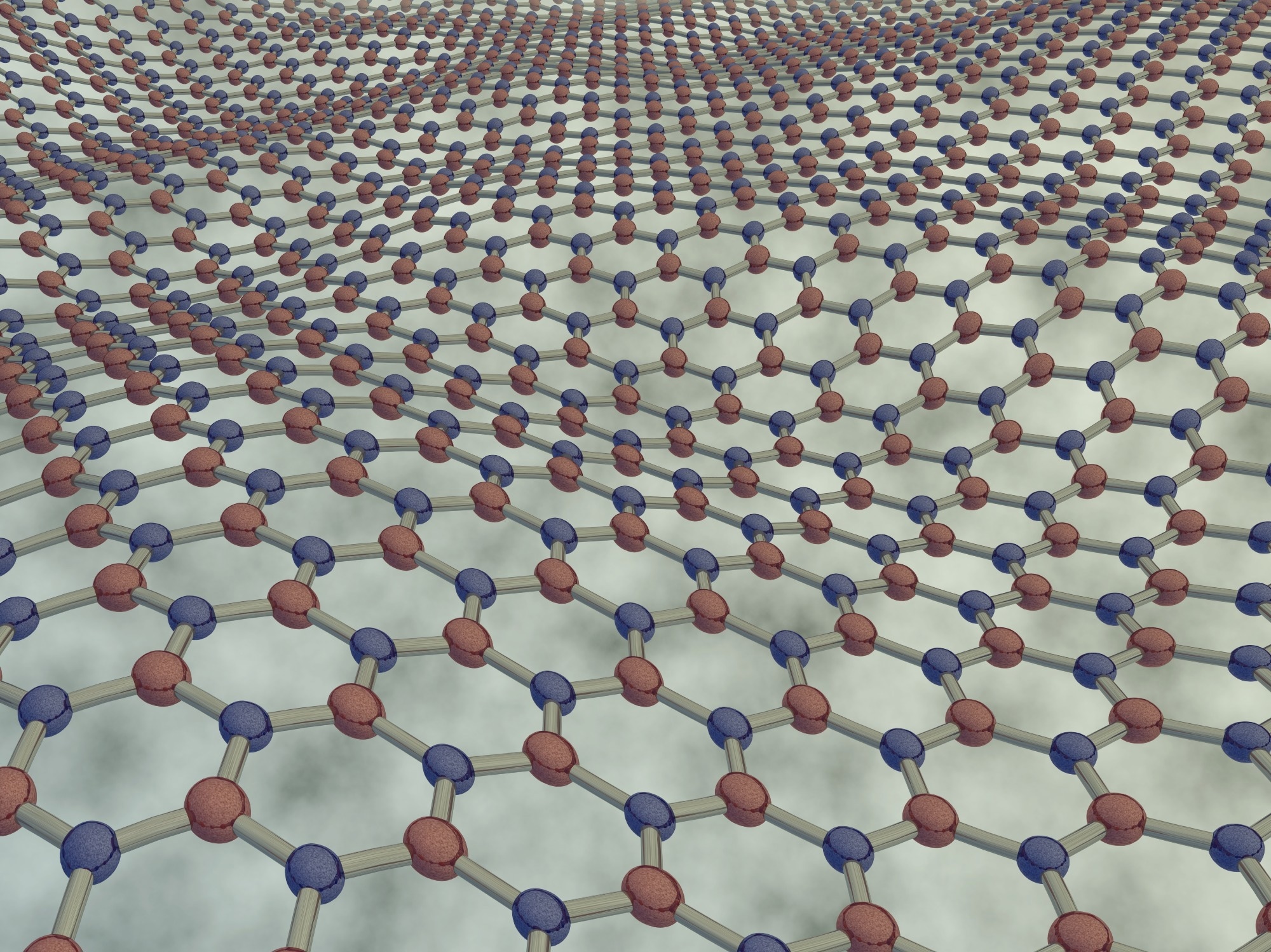

Image Credit: ogwen/Shutterstock.com

Background

Vacancies, topological defects, or grain boundaries significantly impact the properties of two-dimensional (2D) materials. For instance, point defects in hBN can function as quantum emitters with properties such as high stability across a wide temperature range, bright zero-phonon line emission, broad spectral coverage, and potential lifetime-limited emission at room temperature.

Similarly, graphene amorphized through electron irradiation enables the production of free-standing, continuous, and stable monolayer amorphous carbon. However, accurately characterizing the structure of amorphous or highly defective materials remains challenging.

Two practical approaches for obtaining atomic-resolution information are scanning probe microscopy and STEM. STEM, in particular, is more scalable for analyzing large areas of samples but requires freestanding 2D material specimens. Automated image analysis techniques can help address some of these limitations, enhancing the efficiency and accuracy of structural characterization.

Methods

Graphene and hBN samples were prepared on Au Quantifoil STEM grids via chemical vapor deposition (CVD) using commercially available materials from Graphenea© (graphene) and Graphene Supermarket (hBN).

For cleaning, graphene samples were treated with a diode laser (445 nm), while one hBN sample underwent laser pulse cleaning within the STEM imaging column. Another hBN sample with higher defect density was annealed in an ultra-high vacuum (UHV) heating stage at 500 °C for one hour. Following these steps, the samples were exposed to low-energy ion irradiation using a microwave plasma source.

After irradiation, the samples were imaged via STEM under UHV conditions. Graphene was imaged at 40 kV, and hBN at 60 kV. Automated image acquisition enabled the capture of atomic-resolution images across large areas (hundreds of nanometers per lateral dimension), with additional semi-automatic imaging performed for comparison.

Each dataset, comprising hundreds of images, was analyzed using an automated pipeline consisting of three steps: neural network preprocessing, core neural network processing, and postprocessing of the results. The preprocessing model was trained on 170 randomly selected experimental images of graphene and hBN, primarily from low- and medium-defective regimes.

The neural network produced atomic density segmentation maps for each input image. These maps were then analyzed in the postprocessing step to determine atomic positions, providing detailed insights into the structural characteristics of the samples.

Results and Discussion

The graphene and hBN structures displayed notable differences. At the highest defect density, graphene exhibited disordered structures with numerous non-hexagonal carbon rings (amorphization). In contrast, defective hBN largely retained its original crystal structure with minimal non-hexagonal rings.

Postprocessing of graphene using the stable Delaunay graph provided data on defect areas, missing atoms, and ring sizes. This method performed effectively for low to medium defect densities, requiring no manual input. However, at high defect densities, most defects extended beyond the imaged field of view due to extensive lattice amorphization. In this regime, lattice polygon ring sizes were indicators of structural defectiveness.

For hBN, postprocessing involved several steps, including the removal of invalid atomic positions, such as those at image boundaries or within contamination. This process determined the number of connected missing atoms and their species. Like graphene, the core model accurately identified atomic positions across varying defect levels but struggled to evaluate pore structures. For highly defective hBN, local lattice damage was estimated based on the imaged area and porous regions.

The preprocessing neural network struggled with porous hBN and highly defective graphene, necessitating manual threshold selection to calculate porous or defect areas. In contrast, the postprocessing neural network models for graphene and hBN performed well for low to medium defect densities. However, these models were limited to features within the training dataset and demonstrated minimal capacity for extrapolation to more complex structures.

Conclusion

The researchers examined defect regimes in freestanding monolayer graphene and hBN, ranging from pristine material to high defect concentrations and full amorphization. Defects were introduced using low-energy ion irradiation at varying levels.

Thousands of STEM images were semi-automatically acquired to provide detailed statistical representations of defects. The analysis revealed distinct differences between the two materials. In graphene, bond rotations facilitated lattice amorphization, while in hBN, increasing disorder primarily resulted in empty lattice sites without significant changes to the overall crystal structure.

The study demonstrated the effectiveness of combining automated atomic-resolution image acquisition with neural network-based analysis for characterizing 2D materials across different levels of disorder. This approach minimizes human bias in image selection and atomic structure identification, offering a rapid and consistent method for analyzing such materials. However, a fully automated method applicable to any experimental dataset does not yet exist.

Journal Reference

Propst, D. et al. (2024). Automated image acquisition and analysis of graphene and hexagonal boron nitride from pristine to highly defective and amorphous structures. Scientific Reports, 14(1). DOI: 10.1038/s41598-024-77740-9, https://www.nature.com/articles/s41598-024-77740-9

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.