Researchers at TopChim, a developer of materials and technology solutions for the paper industry, have integrated the Zetasizer Nano particle characterization system from Malvern Panalytical into the company’s nanoscience development program. Following five years intensive R&D, one of the first nanoparticle technologies to result from the program was made available commercially last year. The patented NanoTope technology is used in paper production surface treatment and is designed to improve properties without the need for a coating.

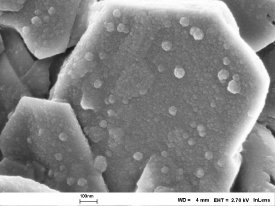

NanoTope products are stable aqueous dispersions of plastic pigments with particle sizes as small as 30 nm. They can be used alone or in combination with a carrier inorganic pigment such as kaoline and calcium carbonate for porous surfaces. The low particle size means that only small amounts of material are required to cover the entire surface.

During the paper production process the NanoTope particles do not film-form. It is this characteristic that is responsible for a number of improvements in the final properties of the paper. For example, ink applied to paper treated with NanoTope dries more quickly as it is drawn into the capillary-like spaces between adjacent particles. Hence image sharpness and depth of colour are improved.

The Zetasizer Nano’s role in the development and manufacture of NanoTope has been two-fold: first in supporting the creation of a stable monodisperse suspension of nanoparticles of defined size; and second in quality control, to ensure the production of consistent materials. This has resulted in good understanding and control of those parameters affecting product performance, shifting quality assurance away from simple reliance on end product testing.

President and R&D manager Henk Van den Abbeele of TopChim said: “The Zetasizer Nano has been crucial to our development of new technologies. We use it to monitor a number of aspects of the products, the most important of which is stability as this is a vital measure of product quality. The impressive repeatability of the system gives us complete confidence in our results.”

Malvern Panalytical’s market leading Zetasizer Nano measures two of the most significant parameters for analyzing nanoparticle dispersions – particle size and zeta potential. It enables non-invasive particle size characterization at high concentration with minimal dilution, and is therefore especially useful for studying aggregates or agglomerates, which are at risk of breakdown when any sample preparation is required. The most popular light scattering system available for nanoparticle characterization, it offers the highest sensitivity combined with real ease of use, measuring particles at the scale of 1 nanometre and below, with minimal training.