Jul 10 2008

Microfluidics, a wholly owned subsidiary of MFIC Corporation, announces methods for processing bulk carbon nanotubes. Microfluidics has devised a methodology to process, deagglomerate, and facilitate purification and stabilization of carbon nanotubes so they can be used in an optimal manner, thus achieving enhanced functionality and performance.

The company has identified and demonstrated several specific operational protocols utilizing its Microfluidizer® processor systems to prepare these bulk nanotubes for their ultimate specific uses. These applications capitalize on the unique mechanical, electrical and thermal properties of carbon nanotubes, and require dispersion of the nanotubes in liquid media and independent length reduction of the carbon nanotubes.

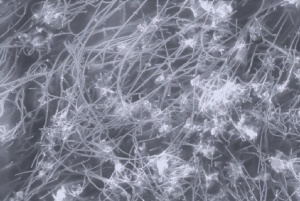

Carbon nanotubes are noted for their tubular shape, extremely small diameter with respect to length, and exceptional physical, mechanical and electrical properties. When prepared in diameters in the 10-50 nanometer range, the unique characteristics of strength, conductivity and quantum behavior become highly desirable and are thus incorporated into a multitude of commercial products.

Microfluidizer® processors are ideal for conditioning carbon nanotubes (and nanomaterials in general) for applications that include high tensile strength polymers, fabric treatments, lubricants, medical therapeutics, computer memory and chips, electronic devices, medical diagnostic biolabels, and photovoltaic cell components.