Sep 24 2008

Hybrid Plastics under sponsorship from The National Science Foundation, Electronics Division, has reached a milestone by producing the first conformal coating capable of suppressing tin whiskers. Lead-free electronics are ubiquitous. Consequently, so is the potential of electronic short circuits from conductive tin whiskers which grow from lead-free solder joints and interconnects.

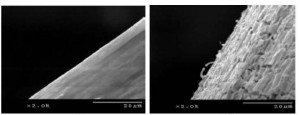

Tin Whiskers with Short-Stop and without Short-Stop (20 ìm)

Tin Whiskers with Short-Stop and without Short-Stop (20 ìm)

The POSS® Short-Stop is optically transparent, colorless and available as a sprayable coating for application to OEM and repair of electronic circuits. The new materials were developed under a Small Business Innovation Research (SBIR) contract between Hybrid Plastics Inc., subcontractor Michigan State University and collaborator Vista Engineering. The effort was focused on solving a well-recognized problem of lead-free solders - the growth of conductive tin-whiskers. Depending on the spacing of interconnects and environmental stress, conductive tin whiskers may grow long enough to create short circuits that cause electronic systems to malfunction or become permanently damaged. The solution was enabled through incorporation of mercapto functionalized Polyhedral Oligomeric Silsesquioxane (POSS) nanocages into polyimide coatings. The mercapto groups bind to the metal surface, protonate through the metal oxide layer and bind to the underlying tin atoms thereby mitigating compressive stress and nucleation of whisker growth. In the event that tin whiskers do grow, a tough high modulus polyimide surface coating is also utilized to force collapse of the whisker and thereby physically isolate whiskers against short-circuiting or detachment.

POSS® [Polyhedral Oligomeric Silsesquioxanes] is a revolutionary new Nanotechnology based on silicon-derived building blocks that provide nanometer-scale control to dramatically improve the thermal and mechanical properties of traditional polymers while offering easy incorporation using existing manufacturing protocols. These compounds have an average diameter of just 1.5 nanometers, or billionth of a meter. POSS® nanomaterials can be used both as direct replacements for hydrocarbon based materials or as low-density performance additives to traditional plastics. They release no VOCs, and, thereby, produce no odor or air pollution. They are biocompatible, recyclable, non-flammable, and competitively priced with traditional polymer feedstocks. POSS® Nanostructured® materials can be readily incorporated into virtually any existing polymer system through blending, grafting or copolymerization.

POSS® nanoscopic chemical technology provides unique opportunities to create revolutionary material combinations through melding the desirable properties of ceramics and polymers at the 1 nm level. These new materials will enable the circumvention of classic material performance trade-offs by accessing new properties and exploiting the synergy between materials that only occur when the length-scale of morphology and the fundamental physics associated with a property coincide on the nanoscale.

These POSS® nanobuilding-blocks were hailed by R&D magazine as one of the 100 globally most technologically significant new products for the year 2000. Hybrid Plastics was one of five finalists in Small Times Magazine’s 2002 Best of Small Tech Award. In December 2005, a Presidential Determination deemed POSS® Nanotechnology to be in the strategic national interest of the United States