Jan 23 2009

Asymtek, a Nordson company (Nasdaq:NDSN) and leader in dispensing, conformal coating, and jetting technologies, and the Fraunhofer Institut für Zuverlässigkeit und Mikrointegration (IZM) Berlin announce their ongoing collaborative effort to support microelectronics packaging and encapsulation research using Asymtek's advanced dispensing and coating technology.

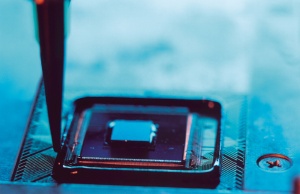

Fraunhofer IZM recently installed Asymtek's Axiom™ X-1020 high volume dispensing system in its Center for Applied Research, which focuses on interconnection technologies and microelectronics. The Axiom system, equipped with the award-winning DispenseJet® DJ-9000 valve, is being used for underfilling inter-chip gaps, wafer level underfilling for Chip-on-Wafer assemblies, and glob top jetting over wire bonds. "The Axiom system offers highly repeatable results that can be easily transferred from our lab to production," stated Karl-Friedrich Becker, group manager, assembly and encapsulation for Fraunhofer Berlin.

Fraunhofer also purchased a Century™ C-341 conformal coating system with the SwirlCoat™ SC-300 valve for the coating of polymer electronics and application of thin hydrophobic layers for electro-wetting on dielectrics (EWOD.) "We chose Asymtek for their technical competence-especially jetting-on-the fly-and the fact that their technology is field-proven," stated Becker. "When we need assistance, they exceed our expectations and help us transition into new products appropriate for our customers' production requirements."

"We are pleased to support the work that the Fraunhofer Institute performs, which helps to advance industry knowledge and practices," commented Michel van de Vijver, Asymtek's general manager for Europe.