Identifying all of the important processing steps is paramount for fully characterizing a plasma process. The steps may include high vacuum preparation, backfill with reagent gases, processing step, and post processing pump down. Hiden’s HPR-30 Series offers diagnostic and data handling capabilities to ensure that key data is regularly measured, logged and interrogated. The article outlines the results of monitoring the different processing steps involved in a wafer device etching stage, using a HPR-30 series instrument.

Step 1: Base Pressure Residual Gas Analysis

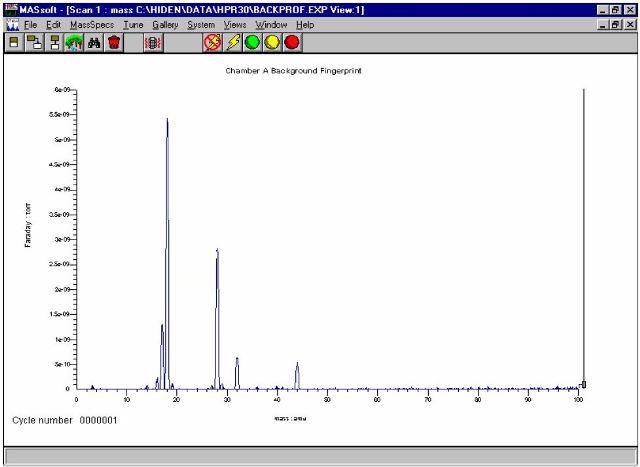

A fingerprint of the residual gases is gathered using the integral “RGA” unit when the process tool is placed under vacuum. The composition of base pressure elements, such as water, hydrogen, and nitrogen, will be revealed through the process (Figure 1).

Figure 1. Base pressure residual gas analysis

This set of measurements will show if any issues need to be resolved, for example whether a bakeout cycle on the chamber is needed or finding the source of an air leak. The residual gas composition can largely affect the process plasma composition, so the gases have to be identified and compared from cycle to cycle. The integrity of certain things can be checked, such as gas feed lines, monitored by acquiring several RGA fingerprints with various components of the tool, isolated from the mass spectrometer.

Step 2: Process Gas Composition Analysis

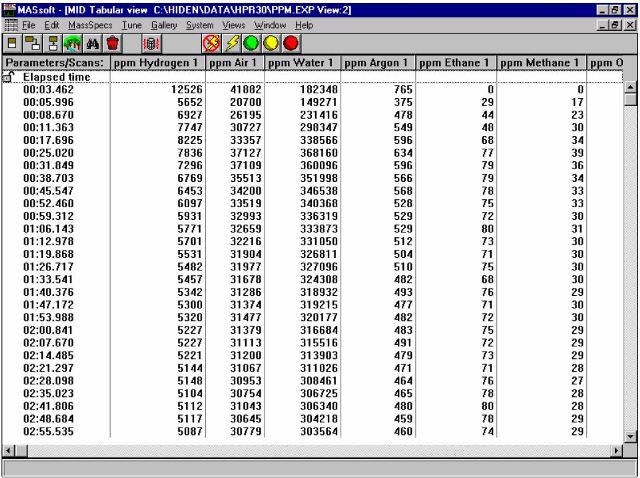

The base pressure analysis is followed by back filling the process chamber with reagent gases, such as chlorine, nitrogen or hydrogen bromide. The HPR-30 will verify the process gas composition, and specify the levels of any contaminants and residuals using the “gas analysis” option.

The combination of base pressure residuals (which are still present during the processing step) and contaminant gases, from the process gas lines and related inlet system, influence the quality of the process. All of the elements can be automatically saved in a template form for future runs and comparative studies between batches (Figure 2).

Figure 2. Process gas composition analysis

Step 3: Plasma Process Fingerprint

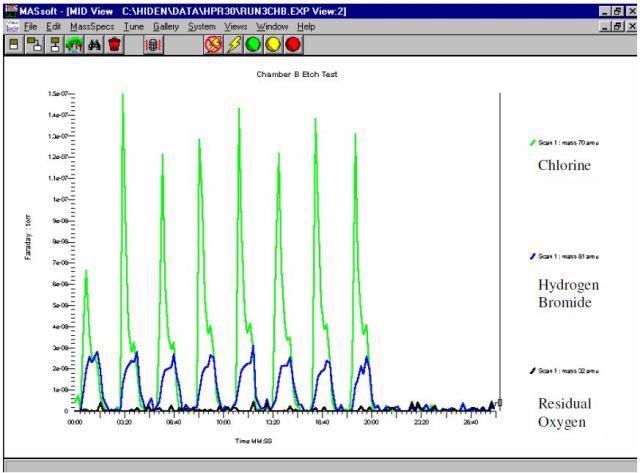

When the chamber is at the correct processing pressure, the plasma is powered on. The neutral gas composition of the plasma can be reviewed and recorded using the gas analysis option and the spectra generated provide a basic fingerprint of the process.

These spectra can be evaluated from batch to batch, and chamber to chamber, to enable transferability and reproducibility. The data signifies a quality control report for each process cycle.

Figure 3. Plasma process characterization

This information has been sourced, reviewed and adapted from materials provided by Hiden Analytical.

For more information on this source, please visit Hiden Analytical.