Cyclic indentation testing refers to applying and releasing indentation load on the surface of a test material using an indenter. This has been one of the primary tests in the area of material testing ever since nanoindentation came on the scene more than two decades ago. Conventional cyclic indentation uses specified loading cycles in which the load is increased step by step up to a maximum, but with the loading rate remaining constant. The iNano nanoindenter from KLA is a leap forward in this field.

Methods and materials

The following experiment uses a diamond Berkovich indenter to apply cyclic indentation on Al 1100.

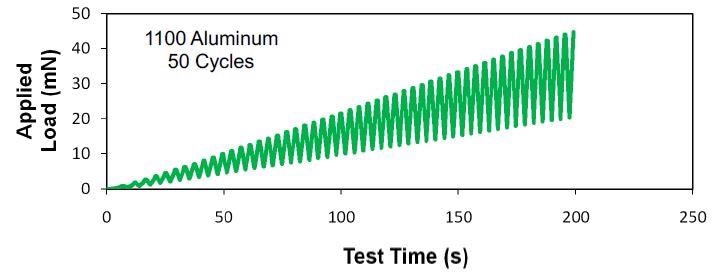

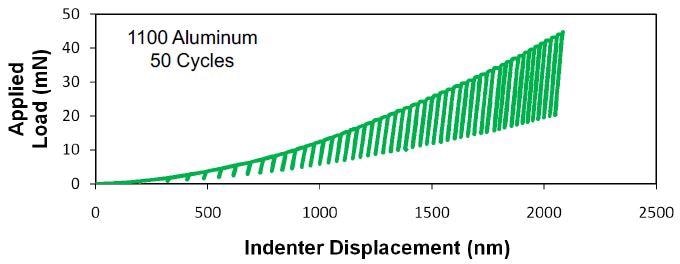

In the first phase, the load was increased linearly up to 45 mN, over 50 loading cycles, with the test time being 200 seconds. The properties were thus measured independently every 4 seconds.

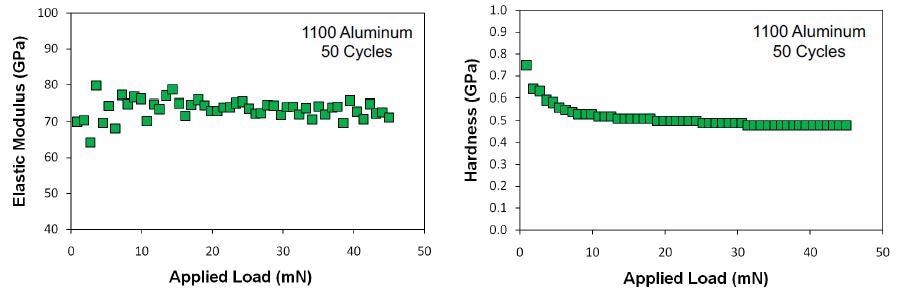

In the second phase, the load-displacement unloading curves were used as the basis for calculating the contact stiffness of the test sample of Al 1100 in each cycle. This was then inserted into the Oliver-Pharr method of calculation to yield the elastic modulus and hardness.

Results

In this case, the results from the iNano nanoindentation testing showed that the average elastic modulus was 73.4 GPa while the hardness follows the indentation size effect that is seen on testing aluminum.

This information has been sourced, reviewed and adapted from materials provided by Nanomechanics, Inc., a KLA-Tencor company.

For more information on this source, please visit KLA.