Shales are among the most complex minerals, or indeed materials, found in nature. The diversity of their structures means that they show a range of mechanical behaviors when studied in bulk. This Eagle Ford play is the single most oil- and gas-rich area in the USA and the shales in this area are rich in carbonate and are derived from the sea, with significant variation in both texture and mineral composition. This is doubtless due to the presence of much organic and mineral deposits here. As a result, it is necessary to study the mechanical properties of each shale component rather than only on the macroscale, so that efficient drilling strategies can be worked out.

Nanoblitz 3D is a state-of-the-art nanoindentation technique which takes only a second to make a single indentation, and can thus be used to map the surface of the test material for mechanical properties such as Young’s modulus and hardness. Nanoblitz 3D is unique in pushing the diamond indenter perpendicularly into the test material rather than dragging it across the material surface. This spares much strain on the tip and prolongs its life. This may be contrasted to the purely relative variations in mechanical characteristics that are brought out by AFM scans due to the lack of knowledge about the tip shape and the fact that the tip is subject to constant wear and tear, which alters its shape.

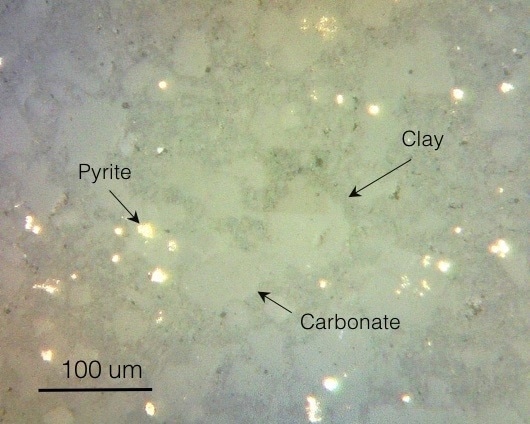

Figure 1. Optical micrograph of shale sample using reflected light. The shining regions are pyrite framboids. Carbonate grains appear as large grey regions, and the rest of surrounding matrix is clay

Materials and methods

In the present study, a small section of Eagle Ford shale from Texas, USA, was cut out in a tiny square of approximately 3 mm by 3 mm with 1 mm thickness. This was then polished by ion milling using a dual-beam argon laser on the test surface. Eagle Ford shale contains several components, mainly clay, carbonate and pyrites. These are present in the surface microstructure of shale that has been prepared for indentation tests, and which contains at least 3 phases. Indentation testing was carried out using an iNano nanoindentater from Nanomechanics, Inc. which had been fitted with a Berkovich tip. The indentations were made using Nanoblitz 3D by which a set of 100 by 100 indents were made in a square covering 50 µm by 50 µm, leaving about 0.5 m. It took about six hours in all to make the 10,000 indents.

The parameters of the test are shown in Table 1:

Table 1. Summary of test parameters for NanoBlitz 3D on Eagle Ford shale

| Input |

Value |

Units |

| Poisson’s Ratio Sample |

0.09 |

None |

| Target Load |

0.5 |

mN |

| Sample Slope |

0.01 |

None |

| X Length |

50 |

um |

| X Points |

100 |

Integer |

| Y Length |

50 |

um |

| Y Points |

100 |

Integer |

| Feature Height |

1000 |

nm |

| Target Decrement |

1 |

None |

Results and discussion

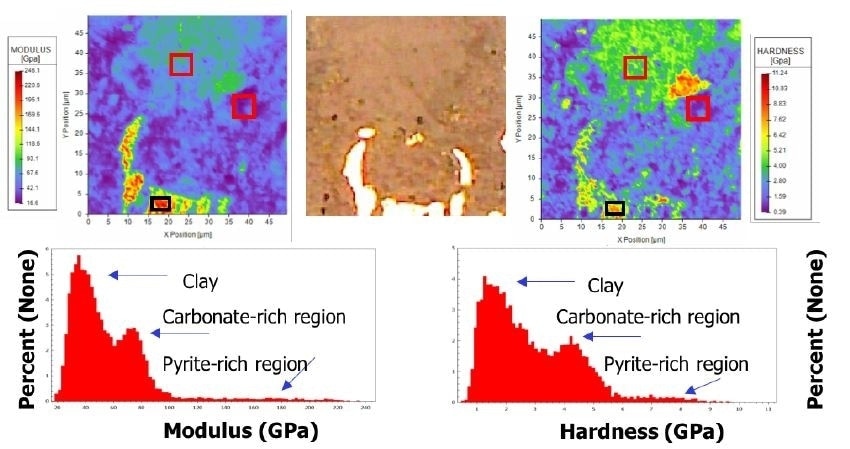

The InView Review program from Nanomechanics is a proprietary data analysis software package which was used to map the elastic modulus and hardness automatically in 3D, using information generated by each indentation, which was enough for one pixel. This enables mechanical properties to be visualized even for materials with multiple phases. A histogram is provided for each map which clearly depicts the maximum percentage of each shale component. Thus both the microscopic picture and the modulus map show how the three phases are distributed within the sample, and the map corresponds to the organization of the shale sample in terms of component percentage. The InView Review from Nanomechanics, Inc. goes further by allowing the user to view a single line from any of its maps by itself.

The last step is to select rectangular areas within the map which are more or less uniform, and then isolate them for the purpose of averaging the elastic modulus and hardness from each of these areas. When these means are compared to those already known for similar materials in existing literature, the degree of agreement is excellent. The phase of shale which is rich in pyrites has an average Young’s modulus value of 199 GPa, which is a little lower than the reference value, because of the presence of clay around the pyrites, which has a yielding nature.

Table 2. Mechanical properties of components of Eagle Ford shale

| Material |

Present work |

Relevant Comparisons |

| |

N |

E (Std.Dev.)

GPa |

H (Std.Dev.)

GPa |

Material |

E |

Ref |

| Phase I (Pyrite-rich) |

14 |

199.16

(25.73) |

7.14

(1.39) |

Pyrite |

250.2 |

(2) |

| Phase II (Carbonate-rich) |

312 |

75.74

(9.82) |

4.38

(0.8) |

Calcite |

72.35-88.19 |

(3) |

| Phase III (Clay-rich) |

41 |

25.60

(5.75) |

1.29

(0.39) |

Clay |

22 |

(4) |

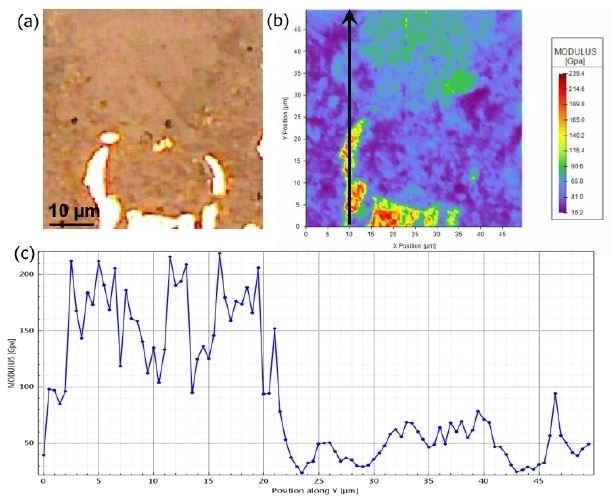

Figure 3. (a) Microscopic image of shale surface, (b) corresponding modulus map, and (c) line profile of modulus corresponding to the black line in Figure 3b..

Conclusions

The experiment shows how the iNano with the NanoBlitz 3D automated technique can be used to study the mechanical behavior of shale. Each phase can be studied separately, and its properties described as percentages of the whole. The resulting values have good concordance with those available in literature for materials of the same kind, proving it to be an accurate method. In short, the NanoBlitz 3D is a valuable technique to delineate the mechanical properties of complex materials quickly, easily, completely and in an organized manner.

References

- http://geology.com/articles/eagle-ford/

- https://books.google.co.in/books?id=naHykL3EnI8C&pg=PA96&lpg=PA96&dq=pyrite+young%27s+modulus&source=bl&ots=iff5LA8BjS&sig=CZGVxA7pz29NKLbpBZvAFNwUCKI&hl=en&sa=X&redir_esc=y#v=onepage&q=pyrite%20young's%20modulus&f=false

- http://www.crystran.co.uk/optical-materials/calcite-caco3

- Hornby, B.E., Schwartz, L.M., & Hudson, J.A. 1994. Anisotropic effective-medium modeling of the elastic properties of shales. Geophysics, 59, 1570–1583.

This information has been sourced, reviewed and adapted from materials provided by KLA Corporation.

For more information on this source, please visit KLA Corporation.