Image Credit: Evannovostro/Shutterstock.com

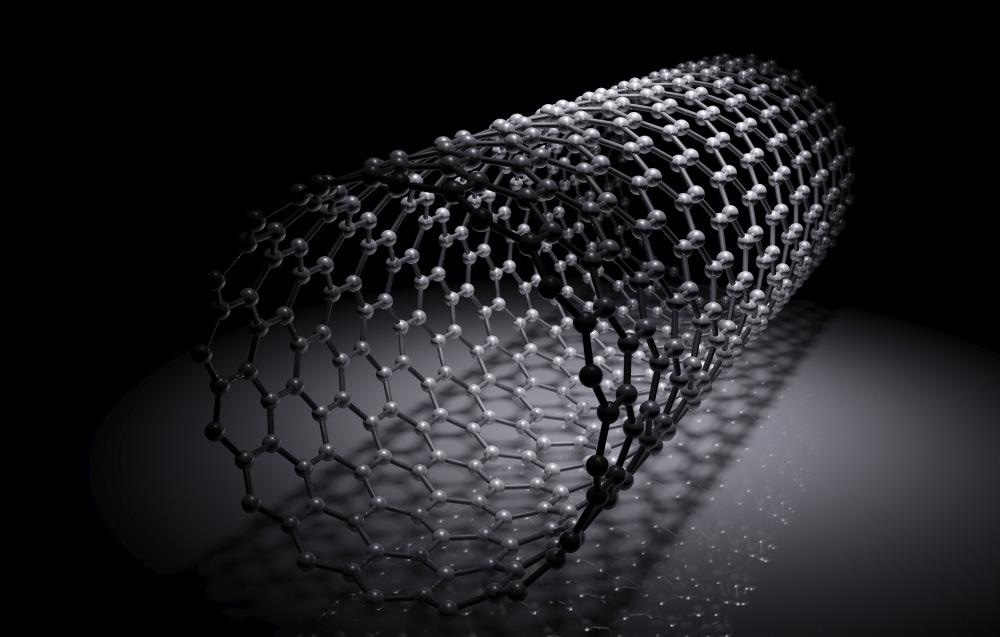

Carbon nanotube sponges are randomly arranged, self-supporting, three-dimensional networks of interconnected carbon nanotubes. Carbon nanotubes are nano-sized structures bearing unique mechanical and conductive properties. The production of carbon nanotube sponges with several unique characters such as high porosity, low density, and excellent elasticity has widened its applicability in science and technology, particularly in environmental research.

Carbon nanotube sponges are enormously light-weighted nanomaterials that can be bent in all directions owing to their high flexibility. They can also take any shape and be recurrently compressed in air or liquids without collapsing. They are also lighter than water.

These nanomaterials can absorb a variety of solvents and oils with great specificity and recyclability. Another interesting characteristic feature is the capacity to absorb up to 180 times its weight, which is significantly more than activated carbon. This nanomaterial is also water repellant in nature.

The most common method for the production of carbon nanotube sponges is chemical vapor deposition. This process involves the utilization of catalyst precursors such as 1,2-dichlorobenzene and ferrocene and a carbon source. These nanomaterials are uniform, highly porous, multi-walled structures with a diameter ranging from 30 to 50 nm, and a length of 10-100s of micrometers.

Properties and Characteristic Features of Carbon Nanotube Sponges

As stated above, a macroscopic image of carbon nanotube sponge revealed unsystematically arranged interconnected individual carbon nanotubes developed by the chemical vapor deposition method. Some of the prominent characteristic features are

- High elasticity

- Elevated strength to weight ratio

- Excellent resistance against fatigue

- Thermo-mechanical durability in wide-ranging temperatures

- Electro-mechanical stability under mechanical compression

- Insignificant stress relaxation under high pressure

The strong inter-tube bonding between the neighboring nanotubes plays a critical role in their alterable deformations. For example, buckling and bending of the carbon nanotube sponges without structural distortion under compression is due to their unique structures.

The mechanical properties and non-linear electromechanical coupling characters are determined with the help of scanning electron microscopy, a study of the structural evolution regarding flexible bending-buckling transition, and nanotube deformation analysis.

The carbon nanotube sponges can be recovered entirely to their full capacity without any plastic deformation. The process of filling the sponge pores with the solvent by reversible absorption and easy solvents removal is highly advantageous. This is because the sponge can completely regain its original shape and size, making the material recyclable.

The thermal conductivity of a carbon nanotube sponge is high. However, it is much less than other insulating materials such as wood and polymeric foam. The ultra-high porosity of the sponges makes them an excellent thermal insulator.

Researchers claimed that these sponges have better applicability than other conventional porous materials because of their superior characters. Some of the characters that make them ideal to other traditional materials are resistance against harsh environments, electrical conductivity, robustness, and thermal stability. Carbon nanotube sponges are used to develop sensors, electrodes, membranes, and high strength-to-weight ratio nanocomposites.

Another essential feature of carbon nanotube sponges is that they consist of both nano- and micro-sized pores that enable easy absorption of heavy oils and sticky and regular fluids. They are also oil-loving and water-resisting, which is why they float on a water pool.

Scientists have recently developed carbon nanotube sponges with high optical antireflection and mechanical stability. The development process involved a continuous winding of hollow cylindrical carbon nanotubes framework and further modifications with amorphous carbon.

The resultant carbon nanotube sponges contain very low optical reflectance at the visible and infra-red spectrum over a wide range of incidence angles. This type of sponge has a high potential for application in different fields such as defense and renewable energy.

Recent Applications of Carbon Nanotube Sponges

Owing to their superior characteristic properties, carbon nanotube sponges are used as nanocomposites in water purification, flexible conductors, sensors, and smart materials. Some of the essential applications of carbon nanotube sponges are discussed below:

Cleaning Up Oil Spills

Oil spills in the ocean occur due to various reasons, such as the toppling of cargo ships and drilling. These oil spills cause extreme harm to the marine ecosystem and aquatic creatures.

Various microbial techniques and functional absorbents are deployed for the cleaning up of the spilled oil from the ocean. Carbon nanotube aerogel/sponge is popularly used to remove and recover the spilled oil and, therefore, clean up the ocean. More generally, this absorbent has superior functioning in absorbance and recovery of different oil and organic solvents.

Some of the other features of carbon nanotube aerogel/sponge absorbents, including high capacity, rapid superhydrophobic/superoleophilic absorption, large surface area, enhanced elasticity and robustness, and high pore density. Owing to their oil-wetting and water-repelling properties, these sponges have specific characteristics, including ''floating-and-cleaning''. This makes them highly beneficial for oil spill cleanups.

Environmental Applications

A carbon nanotube sponge absorbs large liquid volumes, making it highly beneficial to prevent and control industrial chemical leaks. It is also used for retrieving the fluid resources that are polluted by oils and fluids. Carbon nanotubes are also extremely beneficial in reducing water contaminants and can remove toxic organic solvents such as dichlorobenzene from water.

References and Further Reading

Kukkar, D. et al. (2020) Recent advances in carbon nanotube sponge–based sorption technologies for mitigation of marine oil spills. Journal of Colloid and Interface Science. 570, 411-422. https://doi.org/10.1016/j.jcis.2020.03.006

Zhan, H. et al. (2020) Construction of Carbon Nanotube Sponges to Have High Optical Antireflection and Mechanical Stability. ACS Applied Materials & Interfaces. 12 (14), 16762-16771

Dai, Z. et al. (2016) Three-dimensional Sponges with Super Mechanical Stability: Harnessing True Elasticity of Individual Carbon Nanotubes in Macroscopic Architectures. Scientific Reports. 6, 18930. https://doi.org/10.1038/srep18930

Nanotube sponges: Clean it up. NPG Asia Mater (2010) https://doi.org/10.1038/asiamat.2010.27

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.