Extracting, transporting, and processing crude oil has driven the world economy for decades. However, when these activities go wrong, the environment suffers calamitous consequences.

Image Credit: v/Shutterstock.com

Oil spills are not the least of these risks, which remain a significant threat to the environment. A recently published review article examines the potential of carbon nanomaterials in cleaning up oil spills effectively.

Oil Spills: Still a Major Risk

Major oil spill incidents such as the Rayong spill in the Gulf of Thailand (2013), the Tianjin explosion in China (2015), the Agia Zoni II tanker shipwreck in Greece’s Saronic Gulf (2017), the Sanchi tanker going under in the East China Sea (2018), and the headline-grabbing BP Deepwater Horizon spill in the Gulf of Mexico (2010) do not just affect marine life. Such major oil spills also result in human deaths, and their effects are still noticeable in local ecosystems for decades.

Oil spills release heavy hydrocarbons and volatile organic compounds (VOCs) into the marine environment. Primary pollutants from oil spills include petroleum hydrocarbons, heavy metals, and other compounds. These pollutants are neurotoxic as well as carcinogenic.

Part of the cause of these problems is the polar structure of water (H2O) molecules. Because of this, chemical and biological contaminants from oil spills are dissolved and transported through the water cycle, ultimately leading to water contamination that affects aquatic life and human public health.

How Are Oil Spills Traditionally Cleaned Up?

There is currently no generalized method for completely removing oil and other pollutants from oil spills from contaminated water. The processes that are commonly used are inefficient, expensive, and extremely time- and labor-intensive.

Traditional methods can be physical, chemical, biological, or mechanical. Mechanical remediation includes filtration, diffusion, stripping, skimming, in situ burning, gravity separation, emulsification, the use of gelling agents, or the use of membrane bioreactors, dispersers, and solidifiers.

However, the physical and mechanical methods tend to be resource-intensive and inefficient. They also typically generate excessive wastewater that must be safely disposed of.

Chemical and biological remediation includes adsorption, chemical coagulation, burning, phytoremediation, bioremediation, and dispersing. Adsorption is the most well-used remediation method globally due to its simplicity, safety, and efficiency.

Adsorbents used may be natural organic, mineral, or synthetic organic. Natural organic adsorbents are biodegradable but tend to present fire risks, while mineral adsorbents are less hydrophobic than their counterparts.

Synthetic organic adsorbents are much more hydrophobic and are seen by some researchers as a better choice.

Commercial adsorbents include modified clay minerals, activated carbon, zeolites, exfoliated graphite, cellulose, and propylene. However, these materials feature low absorption capacity, poor selectivity, and limited recycling ability.

Carbon Nanomaterials for Oil Spill Clean Up

Nanomaterials (materials with at least one dimension measuring between 0.1 nanometers and 100 nanometers) offer numerous advantages over traditional methods for cleaning up oil spills. For example, they can provide multiple sorption sites. These materials also have a relatively large surface area, exhibit short intra-particle diffusion distance, and can be modified in low-temperature environments with relative ease. The pore size of nanomaterials can also be finely tuned.

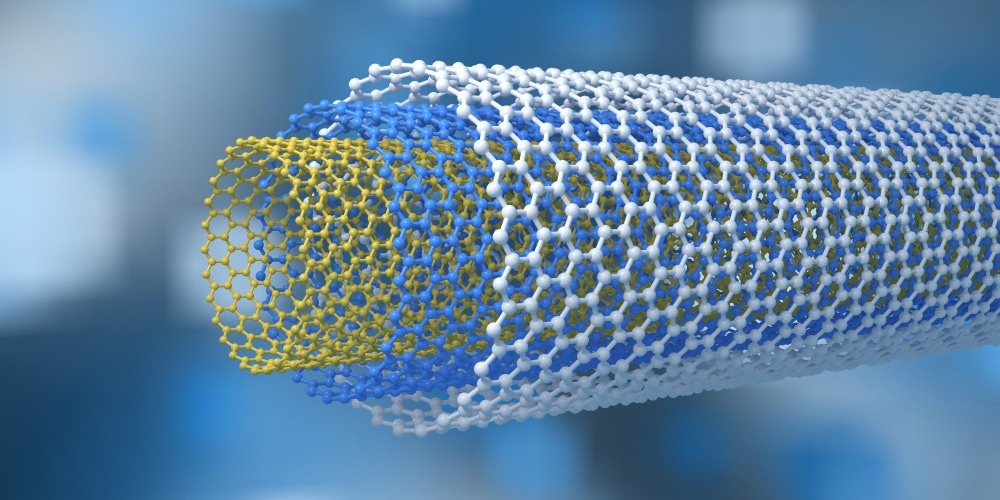

Metal-oxide nanoparticles have been put forward by some scientists; however, carbon nanomaterials tend to receive the bulk of focus in oil spill remediation research. Carbon nanotubes (CNTs), in particular, are of interest.

CNTs are groups of carbon nanomaterials with a tubular structure, with hexagonal carbon atoms covalently bonded together.

CNTs possess numerous features that make them well-suited for application in oil spill remediation. Carbon nanotubes have low density, are electrically conductive, and have a large specific surface area - a trait shared with all nanomaterials.

These carbon nanomaterials also possess high inherent strength, high adsorption capacity, hydrophobicity, thermal stability, chemical stability, and aspect ratio.

Researchers are currently investigating carbon nanotubes for a variety of environmental remediation applications in addition to oil spill management, where organic pollutants and heavy metals must be removed from aqueous media.

Image Credit: ustas7777777/Shutterstock.com

Multi-Walled CNTs and Their Potential Application in Oil Spill Remediation

A recent paper, published in Clean Technologies and Environmental Policy in 2022, provides insight into a specific class of CNTs and their application in oil spill remediation. This review is authored by an international team from institutions in Hungary, Iraq, Korea, Pakistan, Vietnam, and the United States.

The team explored how multi-walled CNTs (MWCNTs) can be used to remove organic pollutants from water. Functionalizing MWCNTs was found to increase traditional adsorbents’ sorption capacity multiple times over. Importantly, they were also found to be compatible with green, biodegradable materials, so MWCNTs could be used for non-toxic oil spill remediation.

The review found that functionalization methods for MWCNTs impact their capability for oil spill remediation. They discovered that MWCNTs could be made with even higher sorption capacities and that including MWCNTs in composites with other materials resulted in even more effective adsorption materials.

Creating a Manufacturing Ecosystem for Carbon Nanomaterials

The missing link between research like this and deployment at scale for more effective oil spill remediation materials is effective synthesis and functionalization.

There is not yet a global industry for producing MWCNTs – or many of the other nanotechnology solutions to environmental catastrophes like oil spills. This is partly due to the relative immaturity of the technologies at hand. There is still research to be done to discover and perfect efficient, cost-effective, and scalable manufacturing techniques for materials such as these.

However, the review authors pointed out that developing these nanomaterials is in the best interests of major oil companies like BP and Shell. These companies currently spend large amounts of money on oil spill remediation and lose public trust when their tankers sink and trigger ecosystem disasters. Investing in effective and efficient remediation techniques can save them money – and face – in the long term.

References and Further Reading

Abdullah, T.A., et al (2021). Promotional effect of metal oxides (MxOy = TiO2, V2O5) on multi-walled carbon nanotubes (MWCNTs) for kerosene removal from contaminated water. Materials Letters. doi.org/10.1016/j.matlet.2021.129612.

Abdullah, T.A., et al (2022). Functionalized multi-walled carbon nanotubes for oil spill cleanup from water. Clean Technologies and Environmental Policy. doi.org/10.1007/s10098-021-02104-0.

Alaa El-Din, G., et al (2018). Study on the use of banana peels for oil spill removal. Alexandria Engineering Journal. doi.org/10.1016/j.aej.2017.05.020.

Al-Jamal, N., et al (2020). Functionalized carbon nanotubes for hydrocarbon removal from water. Journal of Environmental Chemical Engineering. doi.org/10.1016/j.jece.2019.103570.

Apul, O.G., and T. Karanfil (2015). Adsorption of synthetic organic contaminants by carbon nanotubes: A critical review. Water Research. doi.org/10.1016/j.watres.2014.09.032.

Can Nanotechnology Clean Up Oil Spills? (2022) [Online] Science Atlas. Available at: https://science-atlas.com/faq/can-nanotechnology-clean-up-oil-spills/ (Accessed on 17 October 2022).

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.