Radiolysis has gained popularity as an alternate approach for manufacturing nanoparticles. This article discusses the fundamentals of radiolysis, compares it to existing techniques, and explores its merits and scalability.

Image Credit: Kateryna Kon/Shutterstock.com

What is Radiolysis?

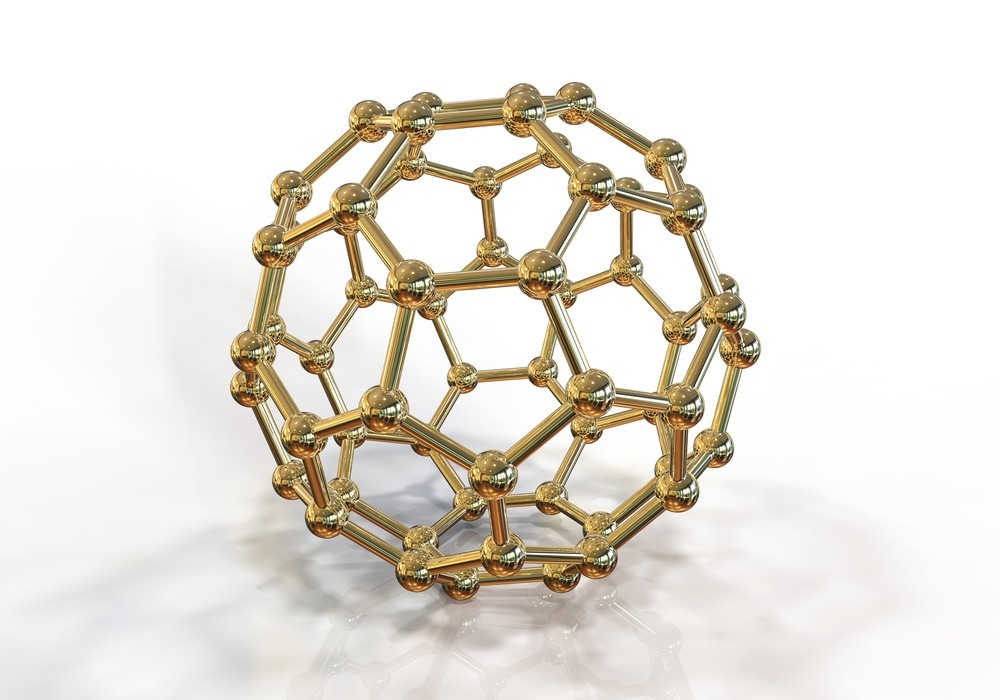

Radiolysis is a technique that uses ionizing radiation, such as gamma rays or electron beams, to convert a precursor solution into radicals and ions, which can subsequently react to generate nanoparticles.

Radiation initiates a sequence of chemical processes that culminate in nanoparticle production. Radiolysis may be used to create a variety of nanoparticles, such as metal, metal oxide, and semiconductor nanoparticles. By altering the radiation dosage, precursor concentration, and reaction duration, it is possible to manipulate the nanoparticles’ size and structure.

Radiolysis chemistry involves the production of reactive chemical species by the dissociation of molecules via ionizing radiation. Radiolysis may be used to create a large variety of monometallic and multi-metallic species from noble metals, as well as transition metals.

Comparison of Radiolysis with Traditional Methods

Radiolysis provides certain benefits over conventional nanoparticle synthesis techniques. It is a process that can create nanoparticles quickly and efficiently. There is no need for reducing agents or hot temperatures, which reduces costs and simplifies the process. The ability to generate nanoparticles with restricted size distribution and excellent purity is a major benefit of radiolysis.

Yet, there are also certain limits to radiolysis. One constraint is the necessity for specialized functional equipment, such as a gamma-ray source or electron beam accelerator. In addition, the dose of radiation must be precisely regulated to prevent over- or under-reduction of the precursor solution.

Advantages of Radiolysis

Radiolysis provides various advantages over conventional nanoparticle synthesis methods. It can create nanoparticles with limited size distribution and excellent purity, both of which are crucial for a variety of applications.

Secondly, it may manufacture nanoparticles of various materials, such as metals, semiconductors, and metal oxides, expanding the spectrum of technologies that can profit from this technique. Radiolysis can be used to produce nanoparticles with unusual features, such as non-spherical forms or high aspect ratios that cannot be obtained by conventional techniques. Radiolysis is a scalable technique that may be applied to mass manufacturing.

Radiolysis gives the unique opportunity to investigate previously unidentified new materials. These unique substances can be described as "kinetically driven," which means that the alloys or crystal structures developed are not energetically favorable and are thus not produced by existing lower-energy synthetic methods.

Controlling the dosage and treatment rate in radiolysis permits exact manipulation of the produced particle's dimensions, morphology, and crystalline structure.

Why Radiolysis or Nanoparticle Production?

To comprehend and develop optimal nanoparticle reaction conditions, the research of nanoparticle production pathways during radiolysis is crucial. Pulse radiolysis is a particularly valuable technique for explaining the processes of reactions occurring over extremely brief timescales.

The intensive and extensive study into nano-alloy production by radiolysis is prompted by the growing number of present (and prospective future) technologies that exploit the nanoparticle's distinctive features. Implementing radiolysis for nanoparticle fabrication is beneficial for applications such as catalysis, hydrogen gas generation, waste management, and the creation of super-alloy materials.

How Feasible is Using Radiolysis at Scale?

Radiolysis is a viable technology for mass-producing nanoparticles. The technique may be readily scaled up by utilizing larger radiation sources and larger precursor solutions. However, there are significant issues that need to be considered when scaling up the procedure.

One problem is the necessity for specific equipment and knowledge to manage the radiation sources properly. Radiation damage to the precursor solution, which can influence the quality and production of the nanoparticles, is another difficulty. This difficulty can be solved by optimizing the radiation dosage and employing radiation-resistant materials.

Latest Research

The latest article published in Scientific reports describes for the first time the prospect of employing radiolysis to build nano-fluids with an increased thermal conductivity that is stable and efficient. The validation was validated on Ag-H2O and Ag-C2H6O2 nano-fluids produced by g-radiolysis in the low dosage range of 0.95*103–2.45*103 Gray.

In stable Ag-C2H6O2 nano-fluids, an increase in effective thermal conductivity of up to 23.57% relative to pure C2H6O2 was found. Radiolysis has the advantages of simplicity, upscaling, mass manufacturing, reduced energy consumption, and no vacuum compared to other nano-fluids synthesis methods.

Future Prospects

Radiolysis for synthesizing nanoparticles has a promising future as experts continue investigating its possibilities and refining its settings for improved effectiveness and scalability.

One area of study that is gaining traction is radiolysis to create complex nanostructures with numerous components. Using radiolysis, scientists have created core-shell nanostructures with a metallic core and a semiconductor shell, which have potential uses in solar cells and photocatalysis.

Creating novel radiation sources that can enhance the effectiveness and sustainability of radiolysis is another topic of study. However, the future of radiolysis for nanoparticle production is contingent upon its commercial feasibility.

In short, radiolysis has the potential to transform nanoparticle production and create new prospects for its usage in a variety of industries.

References and Further Reading

Maaza, M. et. al. (2022). A novel approach for engineering efficient nanofluids by radiolysis. Scientific Reports. 12(1). p. 10767. https://doi.org/10.1038/s41598-022-14540-z

Patil, N. et. al. (2021). Over View on Methods of Synthesis of Nanoparticles. International Journal of Current Pharmaceutical Research, 13(2), pp. 11-16. https://dx.doi.org/10.22159/ijcpr.2021v13i2.41556

Grand, J. et. al. (2018). Nanoparticle alloy formation by radiolysis. The Journal of Physical Chemistry C, 122(24), pp. 12573-12588. https://doi.org/10.1021/acs.jpcc.8b01878

Harish, V. et. al. (2022). Nanoparticle and Nanostructure Synthesis and Controlled Growth Methods. Nanomaterials, 12(18), p. 3226. https://doi.org/10.3390/nano12183226

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.