Semiconductors, also known as microchips or integrated circuits (ICs), are in high demand due to rapid electronic development.1 They form the backbone of devices used in military systems, computing, communications, transportation, healthcare, and clean energy.2

Image Credit: atdigit/Shutterstock.com

Raw Materials and Technologies for Semiconductor Chips

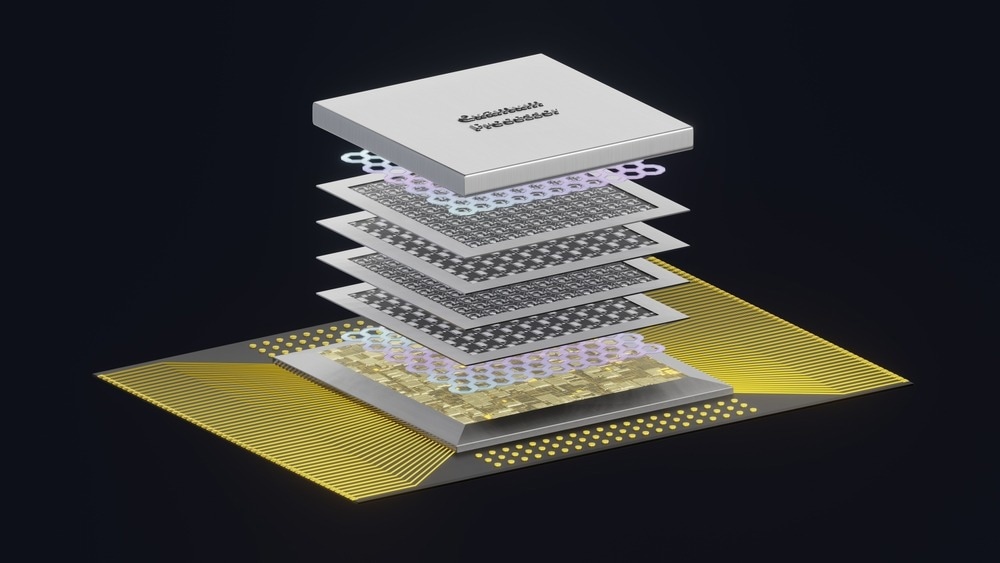

Semiconductor chips consist of dozens of layers, packing immense computing power into a compact form. They store and retrieve data for signaling and control and are essential in creating central processing units (CPUs), power management systems, and graphics processing units (GPUs).3

Semiconductor chips are primarily made from pure elements (such as silicon and germanium) or compounds (like gallium arsenide and indium phosphide).4 These materials are processed into a crystalline structure, forming the foundation of electronic devices.

However, the raw materials often contain impurities like phosphorus, boron, metals, and chemicals, introduced through processes like cleaning, etching, doping, interconnecting, and isolating semiconductors.5

Technological improvements, particularly in photolithography and deposition techniques, have enhanced the performance, quality, and longevity of semiconductors. These improvements have enabled the production of smaller, more complex, and higher-performance devices. Newer semiconductors with wide bandgaps can withstand higher temperatures and operate at higher voltages.6

Key Steps for Semiconductor Chip Manufacturing

The manufacturing time for semiconductor devices can vary from several weeks to months, depending on their specific requirements and complexities.

Semiconductor chip layer development involves multiple steps, including deposition, photoresist, lithography, etching, ion implantation, and packaging. These steps require specialized equipment, facilities, and skilled personnel.

Raw Material Processing

The fundamental building block of semiconductors is silicon, which is melted to create silicon boules. These boules, consisting of 99.99 % pure silicon, are cut into thin wafers (approximately 0.75mm thick) used to manufacture conducting, isolating, or semiconducting materials.7

Doping

Impurities such as boron or phosphorus are added to the wafers to create p-type and n-type semiconductors.8 Doping changes the electrical properties of semiconductors, with p-type containing an excess of holes and n-type containing an excess of electrons. These types are merged to develop the p-n junction, the foundation of many semiconductor devices.

Methods like molecular beam epitaxy (MBE) and chemical vapor deposition (CVD) offer more precise control over the doping process.9

After doping, a thin layer of silicon dioxide is introduced onto the wafer’s surface by exposing it to oxygen at high temperatures. This layer acts as an insulator, protecting the wafer’s surface from electrical charges and stabilizing it for further processing.

Deposition

Deposition involves introducing thin films of material onto a substrate using techniques such as CVD, plasma-enhanced deposition, physical vapor deposition (PVD), roll-to-roll deposition, metal-organic chemical vapor deposition (MOCVD), and atomic layer deposition (ALD).10

Depending on the type of semiconductor, a pattern is deposited on the wafer. Smaller microchip structures demand more complex patterning of wafers. After patterning, thin films of metals and insulators are deposited on the wafer surface to create interconnects and insulators.

Metal films provide electrical connections between active devices, while insulator films protect the device from external damage by providing electrical isolation.

Etching

A mask is developed for the specific patterning of the active device. A light-sensitive material (photoresist) is applied onto the wafer, which is then exposed to light to alter the wafer. The unexposed photoresist material is removed, leaving a pattern on the wafer. This pattern is transferred to the wafer’s surface by etching.

Engineers control the etching process to attain the desired shape and dimension of the pattern. The etching process promotes conductive features without impacting the overall integrity and stability of the chip structure. 11

Photoresists are of two types, positive and negative, based on the chemical structure of the material used to react with light. Positive photoresists become more soluble when exposed to ultraviolet light, aiding the etching and deposition process, while negative photoresists become stronger and more difficult to dissolve upon light exposure.

Lithography

Lithography is crucial in developing a semiconductor microchip because it determines the size of the transistors on a chip. In a lithography machine, the chip wafer is exposed to deep ultraviolet (DUV) or extreme ultraviolet (EUV) light.

Engineers use this technique to introduce the finest details of a chip, which can be thousands of times smaller than a grain of sand.12

Ion implantation

Once patterns are introduced to the wafer, it is bombarded with positive or negative ions to tune the electrical conducting properties linked with the patterns.

Packaging

In the packaging process, semiconductor chips are enclosed in a protective casing with electrical connections. Packing is a crucial step because it influences the performance, reliability, and cost of the final product.13

Challenge and Future Outlook

Despite advancements, semiconductors remain prone to degradation and failure over time. Engineers are focusing on improving technologies to enhance their lifespan and reliability.

Maintaining consistent patterns during lithography is challenging due to particle interference, physical and chemical defects, and refraction.

Computational lithography is used to test wafer patterns, and the increased use of materials like silicon carbide and gallium nitride is expected to improve the performance and longevity of electronic devices in the future.

More from AZoNano: How are Nanoparticles Used for Drug Delivery?

References and Further Reading

- Pennisi, S. (2022). The Integrated Circuit Industry at a Crossroads: Threats and Opportunities. Chips. doi.org/10.3390/chips1030010

- Matsunami, H. (2020). Fundamental research on semiconductor SiC and its applications to power electronics. Proc Jpn Acad Ser B Phys Biol Sci. doi.org/10.2183/pjab.96.018

- Britannica, The Editors of Encyclopaedia. (2024). NVIDIA Corporation. Encyclopedia Britannica. Available at: https://www.britannica.com/money/NVIDIA-Corporation (Accessed 7 June 2024)

- Moskalyk, RR. (2003). Gallium: The backbone of the electronics industry. Minerals Engineering. doi.org/10.1016/j.mineng.2003.08.003

- Lu, X., et al. (2019). Thermodynamic criteria of the end-of-life silicon wafers refining for closing the recycling loop of photovoltaic panels. Sci Technol Adv Mater. doi:10.1080/14686996.2019.1641429

- Yuvaraja, S., et al. (2023), Wide bandgap semiconductor-based integrated circuits. Chip. doi.org/10.1016/j.chip.2023.100072

- Pogue, V., et al. (2018). Residual stresses in multi-crystalline silicon photovoltaic wafers due to casting and wire sawing. Materials Science in Semiconductor Processing. doi.org/10.1016/j.mssp.2017.11.009

- Sadeghfar, F., Ghaedi, M. (2021). Photocatalytic treatment of pollutants in aqueous media. Interface Science and Technology. doi.org/10.1016/B978-0-12-818806-4.00011-5

- Arthur, JR. (2002). Molecular beam epitaxy. Surface Science. doi.org/10.1016/S0039-6028(01)01525-4

- Song, N., Deng, S. (2023). Thin Film Deposition Technologies and Application in Photovoltaics. IntechOpen. doi.org/10.5772/intechopen.108026

- Han, H., et al. (2014). Metal-assisted chemical etching of silicon and nanotechnology applications. Nano Today. doi.org/10.1016/j.nantod.2014.04.013

- Sharma, E., et al. (2022). Evolution in Lithography Techniques: Microlithography to Nanolithography. Nanomaterials (Basel). doi.org/10.3390/nano12162754

- Bender, E., et al. (2024). Modern Trends in Microelectronics Packaging Reliability Testing. Micromachines (Basel). doi.org/10.3390/mi15030398

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.