- High-precision gas adsorption for measuring porosity and surface area.

- Vapor sorption for application-specific investigations.

- Chemisorption and dynamic studies for the characterization of active surfaces.

- Analysis sequencing for automated measurement of chemisorption, dynamic sorption, and physisorption on a single sample.

Powders and particulate materials can have their surface area, pore size, and pore volume measured using the 3Flex high-performance adsorption analyzer. User-customized procedures or standard techniques can be employed to characterize adsorbents, catalysts, zeolites, metal-organic frameworks (MOFs), active pharmaceutical ingredients (APIs), excipients, and a wide range of porous and non-porous materials.

The 3Flex offers exceptional accuracy, resolution, and data reduction and is well suited for gas or vapor adsorption investigation of microporous (<2 nm) and mesoporous (2 to 50 nm) materials.

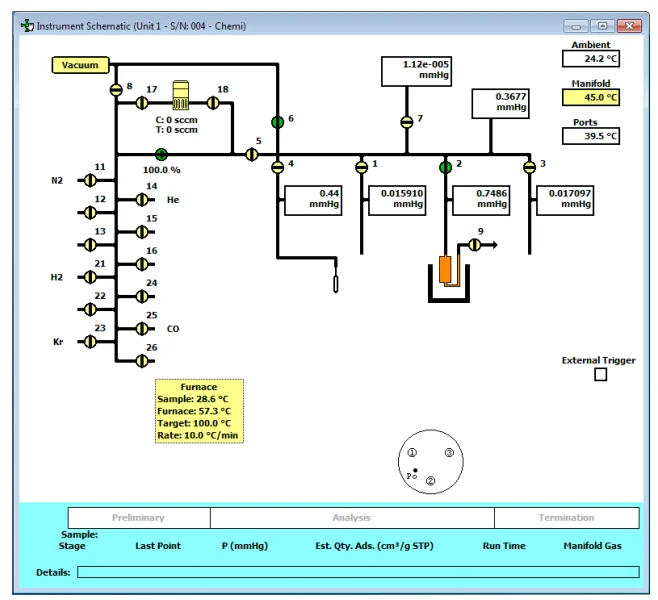

3Flex can now be utilized for physical and chemical adsorption to characterize the active surface and texture of catalysts, catalyst supports, sensors, and a wide range of other materials. This is made possible by the addition of a chemisorption option.

The TCD option adds temperature-programmed and dynamic chemisorption methods, expanding the range of analytical techniques that can be performed with a single adsorption analyzer.

For evaluating textural characteristics and chemisorption, the TCD option includes temperature-programmed reduction (TPR), oxidation (TPO), desorption (TPD), and surface reactions (TPSR). With the inclusion of an automated injection loop, the TCD analytical range can be expanded with the option for pulse chemisorption. A pulse chemisorption TCD is also included in the TCD.

Features and Benefits

High Resolution, High Throughput Physisorption, and Chemisorption Instrument

The 3Flex is recognized as the most advanced material surface characterization instrument in the field. They have become critical tools for advancing and validating fundamental understanding into the creation of techniques and process improvements by offering high-resolution adsorption and desorption isotherms.

Extend and Increase Knowledge

Users can optimize experimental parameters in 3Flex to acquire a better knowledge of the material. Within a single run, the 3Flex can examine a sample with three different probe gases at the same time, one on each analysis port.

Extend the Range of Study

Extend the resolution range beyond micropores to the ultramicroporous level. Users can collect adsorption isotherms and pore size distributions for materials with pores as tiny as 0.3 nm using 3Flex’s sophisticated transducer technology and vacuum management.

Optimize the Material

Users receive useful information using the 3Flex to confirm their hypotheses and rationalize the design and synthesis of MOFs, zeolites, activated carbons, and other products. Use the high throughput findings of the 3Flex’s 3-port mesopore & micropore design to swiftly understand and characterize the surface area, porosity, and adsorption capacity of high-performance materials.

Specifications

Source: Micromeritics Instrument Corporation

| |

|

|

| |

3Flex Physisorption Only |

3Flex Chemisorption |

| Analysis Range |

1.3 x 10-9 to 1.0 P/P0 |

1 x 10-6 to 900 torr |

| Available Micropore Ports |

up to 3 |

up to 3, one port dual purpose chemisorption and physisorption |

| Dosing and Evacuation Control |

Proprietary Servo |

Proprietary Servo |

| Roughing Pump |

4 stage diaphragm |

4 stage diaphragm |

| Krypton Analysis |

Standard 1 port, optional up to 3 ports |

Standard 1 port, optional up to 3 ports |

| Analysis Gas Per Sample |

Ability to use up to 3 gases concurrently, one probe gas on each port |

| Minimum Measurable Surface Area |

Standard 0.01 m2 /g 0.01 m2 /g Krypton 0.0005 m2 /g 0.0005 m2 /g |

| |

3Flex Physisorption Only |

3Flex Chemisorption |

| Temperature Control |

45 °C, ±0.05 °C with 3 strategically placed RTDs |

45 °C, ±0.05 °C with 3 strategically placed RTDs |

| Adsorptive Gas Inlets |

6 |

12 standard; optional up to 16 |

| Vapor Sorption Option |

Standard ports 1 and 2, optional port 3 with heated vapor source |

Standard ports 1 and 2, optional port 3 with heated vapor source |

| Furnace |

N/A |

Ambient to 1100 °C

Programmable from 0.1 to 50 °C/min |

| Mass Flow Controller |

N/A |

Standard, flow up to 200 cm3/min |

| TCD & cold trap for TPx |

N/A |

Optional |

| Automated Loop for pulse chemisorption |

|

Optional and requires TCD & cold trap |

| Dedicated Port for Residual Gas Analysis |

N/A |

Included |

| Software Interface Control (for Calorimeter or Spectrometer) |

Included |

Included |

| Degas |

3 in situ, 6 additional with SmartVac Prep |

3 in situ, 6 additional with SmartVac Prep |

| A/D data acquisition |

29 bit (effective 25) |

29 bit (effective 25) |

| Pressure Transducer System |

up to 12 |

up to 12 |

| Transducer Accuracy |

1000 torr 0.12 % reading

10 torr 0.12 % reading

0.1 torr 0.15 % reading |

1000 torr 0.12 % reading

10 torr 0.12 % reading

0.1 torr 0.15 % reading |

| Cryogen |

|

|

| |

3Flex Physisorption Only |

3Flex Chemisorption |

| Cryogen Dewar |

3.2 L, greater than 70 hrs virtually unlimited with refill during analysis |

3.2 L, greater than 70 hrs virtually unlimited with refill during analysis |

| Cryogen Free Space Control |

Isothermal Jacket |

Isothermal Jacket |

| Reports |

|

|

| Advanced Modeling |

GAB, Sips, Toth, dissociative Langmuir, Redlich-Peterson |

| Instrument Operation Dashboard |

Dashboard permits real-time monitoring of critical parameters |

| Minimized Bench Space Footprint |

| |

3Flex Physisorption Only |

3Flex Chemisorption |

| Height |

112 cm |

112 cm |

| Width |

57.2 cm |

57.2 cm |

| Depth |

61 cm |

61 cm |

Technology

Advancements in Performance and Technology

- Superior mesopore/micropore, physisorption, and chemisorption studies are available. Ports can be set up to analyze krypton in low surface area materials.

- Three customizable analysis ports adapt to the user's workflow requirements.

- The standard setup provides vapor sorption capabilities, and a heated vapor source is offered as an option to increase the analytical range.

- Analysis sequencing of experiments offers the ability to gather surface area and porosity using physisorption, active area, and crystallite size using chemisorption, and TPx data without removing the sample from the analyzer.

- Hard-seal valves and chemically resistant metal seals are elements of the ultra-clean manifold design, which offers chemical compatibility, higher evacuation, and vacuum performance, and the lowest outgassing rate in the sector.

- Saturation pressure can be continuously monitored using a Po port equipped with a specialized pressure transducer.

- The range in which isotherm data collection starts is 10-6 Torr (10-9 relative pressure range for N2).

- The MicroActive™ Data Reduction offers potent yet user-friendly data analysis.

- Gather high-resolution adsorption isotherms quickly using cutting-edge dosing techniques, exclusive hardware, and analyzer control of the adsorbed pressure and volume parameters.

- Minimal footprint preserves important bench space.

- Examine a sample concurrently using three different adsorbent gases, one for each port in a single analysis.

Configurations

Physisorption Option

Advancements in Performance:

Image Credit: Micromeritics Instrument Corporation

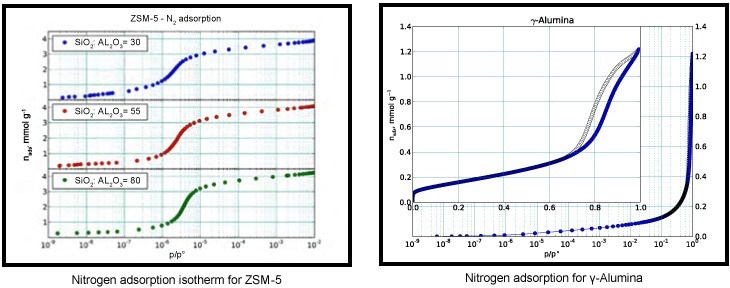

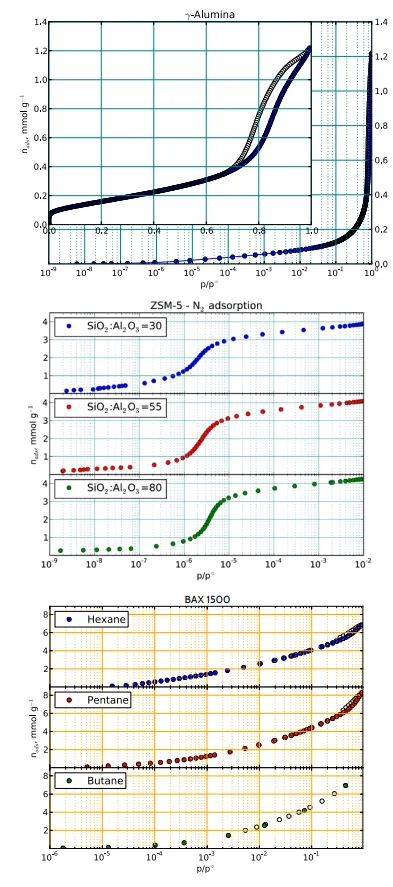

High-Resolution Isotherms

The novel manifold design and inbuilt control create an ultra-stable environment for pressure and temperature monitoring. Aside from hardware upgrades, there have been various software advancements, including a new sophisticated dosing mechanism that allows users to mix pressure and volume increments.

Image Credit: Micromeritics Instrument Corporation

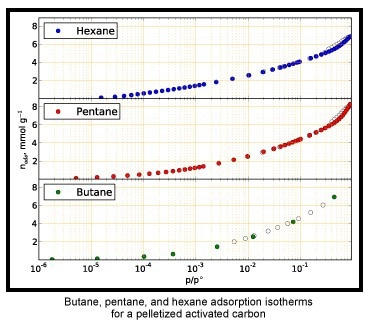

Vapor Isotherms

To optimize analytical capabilities, a wide library of fluid characteristics of fixed gases and regularly used vapors is offered. Isotherm data can be easily acquired when hydrocarbons are used as the adsorptive.

Image Credit: Micromeritics Instrument Corporation

The 3Flex Chemisorption Option

Catalyst Characterization: The Chemisorption Option

Image Credit: Micromeritics Instrument Corporation

The 3Flex is set up to conduct chemical adsorption investigations with the chemisorption option, allowing the researcher to get important data regarding the chemical or physical characteristics of catalysts, catalyst supports, and a range of other materials.

- VCR seals ensure better system cleanliness, lower outgas rates, and lower base pressures. As a result, precise low-pressure chemisorption isotherms are obtained, as well as the capacity to test oxygen-sensitive materials.

- A standard high-precision mass flow controller allows for exceptionally accurate and customizable gas control.

- A high-temperature furnace (up to 1100 °C) offers rapid and precise ramp rates to the required temperature with accurate temperature control and repeatability (±1 °C).

- Multiple probe gases can be explored using up to sixteen gas inlets, enhancing efficiency and application range.

- Superior temperature control maintains repeatability and accuracy in monotonic isotherms.

- The flexible design allows for a quick shift from chemisorption to micropore physisorption within minutes.

- A new high-temperature precision quartz cell boosts accuracy and sensitivity for difficult analyses.

- In chemical adsorption analysis, heated vapor can also be utilized as an adsorptive.

- Chemical compatibility is maximized using Kalrez, Vition, or Buna O-rings.

Only optional level 2 TCD is offered.

Image Credit: Micromeritics Instrument Corporation

Superior Hardware Versatility: Up to sixteen inlets are standard with the chemisorption capability. A mass flow controller (MFC) is used for flow control during sample activation to ensure accurate and consistent sample preparation. The usual chemisorption gear comes with the MFC.

In situ Sample Preparation and Activation: In situ preparation and activation offer a completely automated approach that combines analysis and activation into a single, user-friendly program, eliminating the need for human interaction. Different options for pre-treatment enable oxidation, reduction, evacuation, and purging.

Image Credit: Micromeritics Instrument Corporation

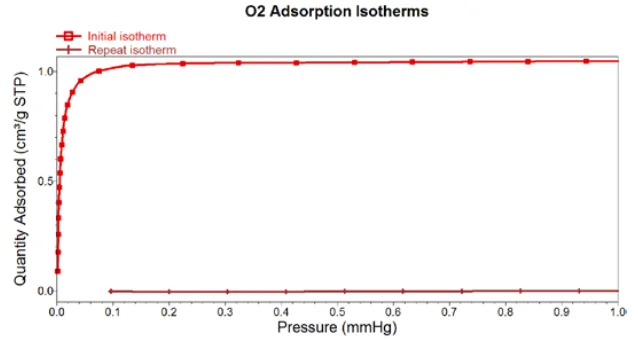

Sample Analysis Options

- Dosing from gas inlets or vapor sources.

- Automatically repeat isotherm to analyze reversible sorption.

- Gas selection.

- Free space measured at both ambient and analysis temperature.

- The pressure table has dosing options that allow users to adjust the volume dosage increment, pressure increment, and equilibrium gap time between data points.

Chemi-TCD Option

Perform High-Resolution TPR, TPO, and TPD Experiments

The most well-known and favored equipment in the industry for physisorption and chemisorption has been enhanced in strength.

TPR, TPO, TPD, and TPRx can now be carried out by the user through dynamic chemisorption analyses, thanks to the inclusion of an inbuilt thermal conductivity detector.

With the TCD option, users can utilize this extremely powerful instrument to study the temperature dependency of certain adsorption or desorption process profiles for catalysts and adsorbents, as well as pulse chemisorption.

Chemi-TCD Available Configurations: Source: Micromeritics Instrument Corporation

| . |

. |

| Level 1 |

Includes injection port, cold trap, and new analysis protocols in MicroActive to support dynamic chemisorption analyses. |

| Level 2 |

Pulse chemisorption adds increased precision, repeatability, and reproducibility by the addition of an injector loop valve with two loop options in addition to four gas inlets, a restrictor for flow control, and an industry-exclusive; local temperature. |

Included Features of the TCD Option:

- The recently updated MicroActive interactive software records the temperature, time, and TCD signal. A complete set of signal processing tools is offered in addition to data collection to convert unprocessed data into sample property information. Peak integration, peak deconvolution (curve fitting), and the computation of active surface area, crystallite size, and dispersion are examples of these tools.

- Precision, detectability, and repeatability of the TCD signal are all improved by industry-exclusive localized loop valve temperature measurement and control.

- Complete flexibility: in only a few minutes, go from chemisorption tests to physisorption analysis.

Image Credit: Micromeritics Instrument Corporation

Accessories

Chiller Dewar

Liquid Recirculation System

Image Credit: Micromeritics Instrument Corporation

The Chiller Dewar from Micromeritics is a closed-loop recirculating system that offers superior heat transmission between the recirculating liquids and the dewar by using a large surface area copper coil. An external recirculating bath or chiller bath, which are available as additional products, enables temperature control.

Source: Micromeritics Instrument Corporation

| . |

. |

| Temperature Range |

-50 °C to 200 °C |

| Temperature Stability |

±0.01 °C |

ISO Controller

Sub-Ambient, Thermoelectric Cooled Dewar

Image Credit: Micromeritics Instrument Corporation

The ISO Controller from Micromeritics uses Peltier-based thermoelectric cooling. The unit is made to have a steady temperature, between -5 °C and 80 °C, when employing CO2, N2, and other gases for adsorption analysis. The device uses extremely little electrical current to quickly cool and effectively maintain temperature.

The dewar section is positioned on the instrument dewar elevator and then lifted into place for analysis.

Source: Micromeritics Instrument Corporation

| . |

. |

| Temperature Range |

-5 °C to 80 °C (lab temp <27 °C) |

| Cooling Capacity |

Approx. 80 W at 0 °C, 120 W at 25 °C |

| Minimum Controllable Resolution |

0.1 °C |

| Temperature Stability |

±0.01 °C |

Cryostat I

Single-Stage Cryogenic Refrigerator Based on the Gifford-McMahon Principle

Image Credit: Micromeritics Instrument Corporation

Based on the Gifford-McMahon (GM) refrigeration concept, the Micromeritics Cryostat I is a closed-cycle cryocooler. It creates cryogenic temperatures using helium gas from a helium compressor.

Liquid nitrogen is not necessary with Cryostat I, which can achieve temperatures lower than 77 K of liquid nitrogen.

Source: Micromeritics Instrument Corporation

| . |

. |

| Temperature Range |

25 to 350 K |

| Temperature Stability |

±0.005 K |

| Nitrogen Reservoir |

closed-cycle helium |

| Cool Down Time to Stated Minimum from Ambient |

60 minutes |

Physi–Consumables and Supplies

Source: Micromeritics Instrument Corporation

| Part Number |

Description |

Notes |

| |

Gas Supply |

|

| 004-62230-32 |

Gas Regulator for CO2 |

2-stage gas regulator, CGA 320, delivery pressure range: 2-30 psig |

| 004-62230-58 |

Gas Regulator for He, N2, Kr, Ar |

2-stage gas regulator, CGA 580, delivery pressure range: 2-30 psig |

| 004-25549-00 |

Reducer 1/8 in Tube x 1/4 Tube |

|

| 004-33601-00 |

Gas Regulator Expansion Kit |

Adds an additional outlet to the gas regulator |

| 004-33602-00 |

Gas Regulator Pressure Relief Kit |

Prevents excessive gas pressure in the event of a regulator failure (not to be used with toxic gases) |

| 290-25846-00 |

Gas Inlet Line 6' |

For connecting gas to the instrument, Copper, 1/8 in x 6 ft long |

| 290-25846-01 |

Gas Inlet Line 16' |

For connecting gas to the instrument, Copper, 1/8 in x 16 ft long |

| |

Vacuum Supply |

|

| 004-25509-00 |

Clamp |

NW 10/16, clamp to connect flex tube to pump or instrument |

| 004-25626-04 |

Flex Tube |

3/4 in OD x 48 in long, NW 16, tube to connect the pump to the instrument |

| 004-25630-00 |

Centering Ring |

NW 16, sealing ring to connect forepump to instrument |

| 062-62803-00 |

Dry Diaphragm Vacuum Forepump |

Without tray |

| 350-34026-00 |

Hybrid Pump |

5×10-9 mbar |

| 004-62023-01 |

Service Kit Vacuum Forepump |

|

| |

Reference Materials |

|

| 004-16844-00 |

Reference Material Y Zeolite |

Micropore reference material |

| 004-16821-00 |

Reference Material Silica Alumina |

Reference material for surface area and pore volume, S(BET) appr. 200 m2/g |

| 004-16833-00 |

Reference Material Carbon Black |

Reference material for surface area, S(BET) appr. 30 m2/g |

| 004-16816-00 |

Reference Material Alumina |

Reference material for surface area with Krypton analysis, S(BET) appr. 0.25 m2/g |

| |

General Operating Supplies |

|

| 003-63801-01 |

Cable Ethernet Straight-Thru |

For connecting the instrument to a computer |

| 350-25853-04 |

Shield for Dewar and Chemisorption Furnace |

|

| 350-25825-00 |

Dewar |

3.2 ltr |

| 240-25901-00 |

Dewar Dip Stick |

For checking liquid nitrogen level in Dewar |

| 350-31701-00 |

Dewar Lid 12 mm |

For 12 mm sample tubes |

| 350-31700-00 |

Dewar Lid 9 mm |

For 9 mm sample tubes |

| 350-26012-00 |

Heating Mantle for in-situ Degas |

For degassing samples in-situ on 3Flex ports, up to 400 °C |

| 350-33013-00 |

Heating Mantle for in-situ Degas |

For use on instruments below serial number 200, includes adapter to connect to 1st generation 3Flex |

| 350-26004-00 |

Heating Mantle for Vapor Source |

|

| 011-62700-11 |

Air compressor, 115 V |

2.12 CFM, for operation of pneumatic valves |

| 011-62700-23 |

Air compressor, 230 V |

2.12 CFM, for operation of pneumatic valves |

| 350-53700-00 |

Degas Mantle Top |

Degas mantle top for 350-26000-00 (Glascol mantle) |

| 350-53701-00 |

obsolete |

|

| 350-53701-01 |

Heating Mantle Top for 350-53701-00 |

|

| |

Sample Tubes and Accessories |

|

| 350-33610-00 |

Extended Operating Supplies, 12 mm |

Includes: 9 sample tubes (12 mm OD), 3 isothermal jackets, 1 service kit, reference materials, filler rods, O-rings, and other accessories |

| 350-33609-00 |

Extended Operating Supplies, 9 mm |

Includes: 9 sample tubes (9 mm OD), 3 isothermal jackets, 1 service kit, reference materials, filler rods, O-rings, and other accessories |

| 350-33603-00 |

Sample Tube Kit 12 mm |

Includes: 9 sample tubes (12 mm OD), 9 O-rings, 9 stoppers, 3 isothermal jackets, 1 Dewar lid, 3 hanging filler rods, 1 sample tube brush |

| 350-33604-00 |

Sample Tube Kit 9 mm |

Includes: 9 sample tubes (9 mm OD), 9 O-rings, 9 stoppers, 3 isothermal jackets, 1 Dewar lid, 3 hanging filler rods, 1 sample tube brush |

| 350-61002-03 |

Sample Tube 12 mm |

Flat bottom |

| 350-61002-02 |

Sample Tube 9 mm |

Flat bottom |

| 350-25812-03 |

Isothermal Jacket for 12 mm Sample Tube |

Ensures stable analysis temperature in sample tube |

| 350-25812-02 |

Isothermal Jacket for 9 mm Sample Tube |

Ensures stable analysis temperature in sample tube |

| 350-61003-01 |

Hanging Filler Rod for 12 mm Sample Tube |

Reduces Free Space in sample tube |

| 350-61003-00 |

Hanging Filler Rod for 9 mm Sample Tube |

Reduces Free Space in sample tube |

| 004-32004-00 |

Rubber Stopper |

For sample tubes (fits various sample tube sizes) |

| 350-25843-00 |

Ferrule for 12 mm Sample Tube |

For fitting the tube to the sample port |

| 350-25843-01 |

Ferrule for 9 mm Sample Tube |

For fitting the tube to the sample port |

| 004-25013-02 |

O-Ring for 12 mm Sample Tube |

Viton, Brown |

| 004-25079-06 |

O-Ring for 9 mm Sample Tube |

Viton, Brown |

| 350-25864-00 |

Check Seal Assembly for 12 mm Sample Tubes |

Includes: 1 CheckSeal with alternate size O-rings and Filler Rod |

| 350-61004-00 |

Filler Rod for CheckSeal |

|

| 350-33607-00 |

Check Seal Kit for 12 mm Sample Tubes |

Includes: 9 CheckSeals with alternate size O-rings, 9 Filler Rod, 6 openers for Smart VacPrep Ports, 3 openers for 3Flex sample ports, 1 extractor tool for CheckSeal opener, and installation instructions |

| 350-33608-00 |

TranSeal Kit for 12 mm Sample Tubes |

Includes: 3 TranSeals with alternate size O-rings and installation instructions |

| 004-27070-00 |

Sample Port Frit |

20 µm, 1/4 in |

| 004-25040-06 |

Gasket 1/2 in, SS, Retainer Assembly |

|

| 004-25040-05 |

Gasket 1/4 in, SS, Retainer Assembly |

VCR sealing for sample port and P0/ vapor source port |

| 004-54618-00 |

Tool for Removing the Sample Port O-ring |

|

| 240-14855-00 |

Sample Tube Holder |

Rack for 12 sample tubes |

| 300-32800-00 |

Support for Sample Tube Weighing |

Sample tube holder for balance |

| 240-25853-00 |

Funnel |

For sample tubes (fits various sample tube sizes) |

| 004-54104-02 |

Brush |

For cleaning sample tubes, 16 in long |

| |

Software and Manual |

|

| 350-20800-00 |

3Flex Software |

Current version software |

| 350-42800-00 |

3Flex Operator Manual |

|

| |

Degas Devices |

|

| 060-00035-00 |

FlowPrep 060 for 3Flex |

Degasses up to six samples at up to 400 °C with flowing gas. A gas regulator is required. |

| 061-00035-00 |

VacPrep 061 for 3Flex |

Degasses up to six samples at up to 400 °C; uses flowing gas or evacuation by vacuum. Evacuation requires a vacuum pump, gas source, and gas regulator required. |

| |

Smart VacPrep |

Is an advanced six-port system that utilizes a vacuum to prepare samples by heating and evacuation. Each of the ports may be operated independently. Samples may be added or removed from degas ports without disturbing the treatment of other samples undergoing preparation. Degassing automatically terminates when the samples have completed all programmed steps. |

| 067-00000-00 |

Smart VacPrep without Vacuum Pump |

|

| 067-00000-11 |

Smart VacPrep with Vacuum Pump, 110 V |

|

| 067-00000-22 |

Smart VacPrep with Vacuum Pump, 230 V |

|

| 067-00001-00 |

Smart VacPrep with High-Vacuum Pump |

|

| |

Temperature Control Devices |

|

| 350-33005-00 |

ISO Controller |

Micromeritics’ ISO Controller utilizes thermoelectric cooling based on the Peltier principle. The unit is designed to maintain a constant temperature between 0 °C and 80 °C when using CO2, N2, and other gases for adsorption analysis. The device rapidly cools and efficiently maintains temperature with minimal electrical current required. The sample area will accommodate up to 3 sample tubes. Heat removal is uniform and accurate when the unit is used with an appropriate liquid (ambient water or liquid antifreeze). The dewar section is placed on the instrument dewar elevator and then raised into position for analysis. |

| 025-00350-00 |

Chiller Dewar |

A closed plumbing system that circulates fluid from a temperature-controlled bath into a small Dewar filled with antifreeze in which the sample tubes are immersed. |

| 025-26002-00 |

Recirculating Bath |

Temperature range from -28 °C to 200 °C, 230 V, 50 Hz. Refrigerated and heating circulator for temperature control of the Chiller Dewar. Note: Recommended for use with the Chiller Dewar Option 025-00350-00 |

| 026-00350-00 |

Cryostat |

The Micromeritics Cryostat is a closed-cycle cryocooler based on the Gifford-McMahon (GM) refrigeration principle. It uses helium gas from a helium compressor to generate cryogenic temperatures. The refrigeration effect of the GM cooler results from a series of thermodynamic processes acting on the helium gas that includes: charging and compression, displacement and heat exchange with the regenerator, expansion, and heat absorption (cooling effect). |

| 021-00000-00 |

LN2 transfer system |

For easy filling of sample Dewars; includes 47 L Dewar, mobile platform, and pump with 100 cm discharge line |

3Flex Chemi-Consumables & Supplies

Chemi–Consumables & Supplies

Source: Micromeritics Instrument Corporation

| Part Number |

Description |

Notes |

| |

Gas and Vacuum Supply |

|

| 004-25318-00 |

Reducer - for Chemisorption |

1/4 stub × 1/8 tbg, SST |

| 201-25818-00 |

Gas Inlet Line for Chemisorption |

Gas Inlet Line, SS 6 ft |

| 004-28998-02 |

Clamp, Hose |

For Chemisorption Clamp, Hose, 7/32 in - 5/8 in |

| 350-32802-00 |

Exhaust tube for instrument |

1/4 in ID x 10 ft long, to connect instrument exhaust with lab ventilation system. |

| 350-32801-00 |

Exhaust tube for vacuum pump |

3/8 in ID x 10 ft long, to connect vacuum pump exhaust with lab ventilation system. |

| |

General Operating Supplies |

|

| 350-63835-00 |

Cable for Sample Thermocouple |

DB9, Type K |

| 004-28410-01 |

Clip for Sample Thermocouple |

For standard chemisorption sample tube |

| 004-25891-00 |

Clip for Sample Thermocouple |

For use with bulb sample tube |

| 350-31720-00 |

Furnace Insulator Set |

|

| |

Reference Materials |

|

| 004-16825-00 |

Reference Material Platinum on Alumina |

Reference material for active metal dispersion |

| |

Sample Tubes and Accessories |

|

| 350-33635-00 |

Extended Operating Supplies (6-month supply) for Chemisorption |

Includes: O-rings, sample port dust frit, reference material, furnace insulator set, quartz hanging filler rod assembly, quartz wool, quartz filter discs, sample tube brush, sample tube stoppers, and exhaust tubing. NOTE: Sample tubes are not included in the 3Flex Chemisorption Extended Operating Supplies. Sample tubes must be ordered separately. |

| 350-33632-00 |

Extended Operating Supplies (12-month supply) for Chemisorption |

Includes: O-rings, sample port dust frit, reference material, furnace insulator set, quartz hanging filler rod assembly, quartz wool, quartz filter discs, sample tube brush, sample tube stoppers, and exhaust tubing. NOTE: Sample tubes are not included in the 3Flex Chemisorption Extended Operating Supplies. Sample tubes must be ordered separately. |

| 350-61030-00 |

Sample Tube Flow Thru, Quartz, 12 mm |

|

| 350-61032-00 |

Sample Tube Flow Thru, Quartz, 12 mm, 6 cc Bulb |

|

| 350-61003-02 |

Hanging Filler Rod for Chemisorption Tube, Quartz |

|

| 240-32000-00 |

Stopper for Chemisorption Tube |

|

| 004-25225-02 |

Ferrule 6mm, Rear, Stainless Steel |

For chemisorption exhaust port |

| 350-25874-03 |

Nut for Chemisorption Exhaust Port, 6mm |

|

| 004-25474-00 |

O-Ring for Chemisorption Tube, Sample Port |

Kalrez |

| 004-25079-10 |

O-Ring for Chemisorption Tube, Exhaust Side |

Viton, Brown |

| 004-25678-00 |

O-Ring for Chemisorption Tube, Exhaust Side |

Kalrez |

| 350-33636-00 |

Kit Kalrez O-Rings for 3Flex |

Includes: 2 O-Rings for Sample Port and 2 O-Rings for Exhaust Port |

| 004-32164-01 |

Quartz Wool |

|

| 004-54805-00 |

Stuffing Extractor Tool for Removing Quartz Wool |

|

| 248-32702-00 |

Filter Disc, Quartz (qty. 100) |

|

| 350-61033-00 |

Glass Rod for Filter Disc Installation |

|

| 350-33032-00 |

Quartz Filter Discs Kit |

Includes: quartz filter discs (pack of 100), quartz filter discs instructions, glass rod for filter disc installation |

| 350-25875-00 |

Stand for Sample Tube Weighing |

|

| 004-54609-0 |

Brush for Cleaning Chemisorption Tube |

3 mm Dia x 20 mm X 300 mm LG |

TCD–Consumables and Supplies

Source: Micromeritics Instrument Corporation

| Part Number |

Description |

Notes |

| |

Reference Materials |

|

| 004-16825-00 |

Reference Material Platinum on Alumina |

Reference material for active metal dispersion |

| 004-16828-00 |

Reference Material Cupric Oxide |

Reference material for TPR |

| 004-16836-00 |

Reference Material Silver Oxide |

Reference material for TPR |

| 004-16848-00 |

Reference Calcium Oxalate Monohydrate |

Reference material for TPD |

| |

General Operating Supplies |

|

| 004-32602-00 |

Septum |

|

| 004-61602-00 |

Syringe, 1 mL |

|

| 004/61604/00 |

Syringe, 10 mL |

|

| 004-61604-01 |

Syringe Needle |

3/4 x 029 x 012, 3/Pkg, Needle for 1 mL and 10 mL Syringe |

| 230-61001-00 |

Tube for Cold Trap |

|

Application

Metal-Organic Frameworks and Porous Organic Polymers

Empowering the Study of Energy Storage and Gas Separations by MOFs and porous-organic polymers (POPs).

Investigate the Influence of Hydrogen Adsorption Enthalpy

3Flex can quickly transition from physisorption to chemisorption, allowing for the examination of enthalpy related to ligand impact.

Determine the Influencing Relationship of Surface Area, Pore Volume, and Substrate/Analyte Interactions for Uptake, Capacity, and Release Evaluations

In a single run, the 3Flex can examine a sample with three different probe gases at once, one on each analysis port.

Evaluate Optimal Small Pore Size as A Strategy to Enhance Hydrogen–Framework Interactions

Accurate and precise micropore and ultra-micropore (<0.7 nm) measurements are made possible by superior gas management and temperature control.

Advanced Pore Size Analysis with NLDFT Models

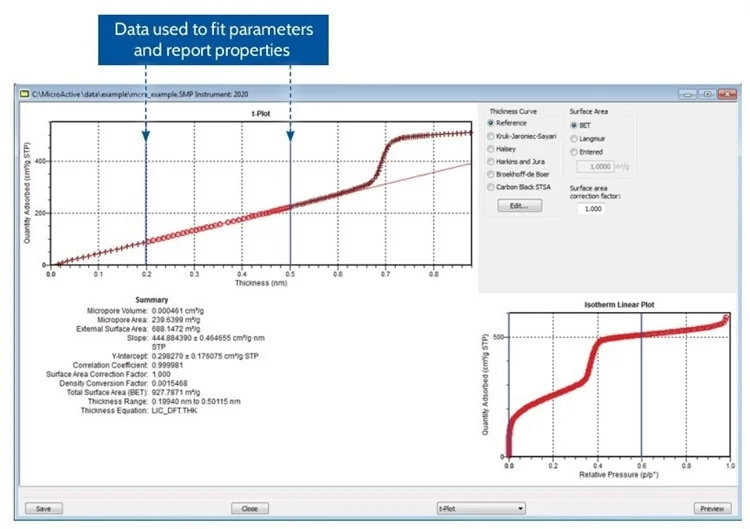

Using an intuitive user interface, MicroActive™ Data Software enables users to graphically record the relevant range of isotherm data, saving you time and effort when converting data into textural information like surface area and pore size.

The potent reporting software allows users to export the data to a spreadsheet, save it to PDF, or print reports. The MicroActive user interface lets users copy and paste data to the preferred program for additional analysis or custom plotting.

Advancing the Understanding for Strategy and Synthesis in Zeolite Design

Quantitatively Determine the Number of Surface Active Sites for Catalytic Potential

Provide information on the catalysts’ dispersion, metal area, monolayer uptake, and crystallite size. The 3Flex's exceptional versatility enables complete characterization with a single instrument by enabling users to switch in minutes from physisorption analysis to chemisorption analysis.

Determine if Zeolite Processing Has Resulted in Loss of Structure or Degradation

The 3Flex’s sophisticated architecture offers the best micropore resolution in the market. It also offers complementary information and X-Ray diffraction to address small structural flaws brought on by processing.

The Advanced Design of the 3Flex Provides Industry Leading Resolution and Accuracy

Acquire valuable insights about pore architecture to improve the understanding of selectivity, diffusion rates, and transport.

Gain Valuable Data for Improving Activated Carbon Adsorbents and Catalyst Performance

Determine Adsorption Dynamics in Regard to Resident Time for Performance in Fixed Bed and Flow Through Systems

Understand how surface area, pore volume, and pore size distribution affect performance.

Gain Valuable Insight of Structural and Chemical Heterogeneity Influence on Adsorption Dynamics

Superior gas management, hard seal valves, metal seals, and precise temperature control allow for accurate and exact micropore measurements.

Evaluate Temperature and Chemical Deactivation Processes in Regard to Porosity and Surface Activity

Temperature and gas control accuracy provide consistent analytical results from sample to sample and batch to batch.

High-Resolution and Vapor Isotherms

Image Credit: Micromeritics Instrument Corporation

The innovative manifold design, together with inbuilt control, creates an ultra-stable environment for pressure and temperature monitoring. Aside from hardware enhancements, software advancements include a new enhanced dosing approach that enables users to mix pressure and volume increments.

The 3Flex comes with a large library of fluid characteristics for fixed gases and regularly used vapors. Isotherm data can be easily acquired when hydrocarbons are used as the adsorptive.

Software

Data Reduction and Control Software

MicroActive for 3Flex – Data Reduction and Control Software

- Direct interaction with adsorption/desorption data is possible. The user is immediately updated with new textural properties by simply adjusting the calculation bars.

- Click-and-drag bars slide to pick the computation range, reducing the utilization of dialog boxes and tunneling of dialogs to define the calculation parameters.

- User-customizable data ranges through the graphic interface, enabling direct modeling for BET, BJH, t-Plot, Langmuir, DFT interpretation, and more. MicroActive isotherm analysis software includes a large number of NLDFT models for estimating pore size distributions.

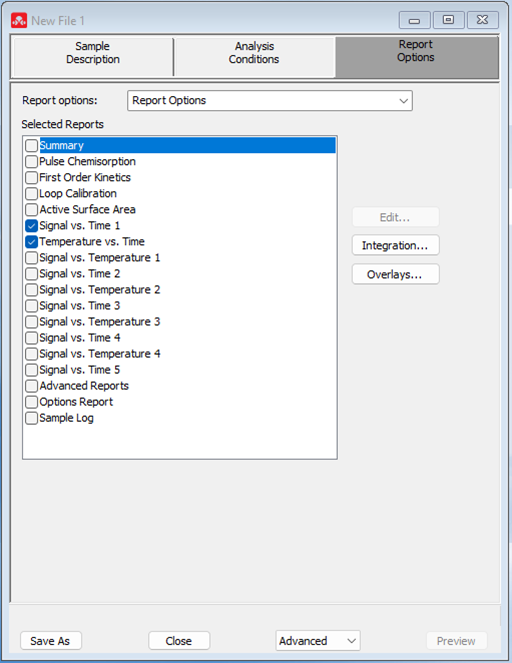

- Users can define reports with on-screen previews using the Report Options editor.

- Python programming interface for user-defined reports is included.

- Mercury intrusion findings can be superimposed with pore size analysis from the 3Flex on up to 25 files.

t-Plot analysis of N2 at 77 K on MCM-41 silica. The t-Plot calculation shows this is not a microporous material despite the large gas capacity. Image Credit: Micromeritics Instrument Corporation

3Flex Interactive Reports Include:

- Horvath-Kawazoe

- MP-Method

- DFT Pore Size and Surface Energy

- Dubinin-Radushkevich

- Dubinin-Astakhov

- User-Defined Reports (5)

- Isotherm

- BET Surface Area

- Langmuir Surface Area

- t-Plot

- Alpha-S Method

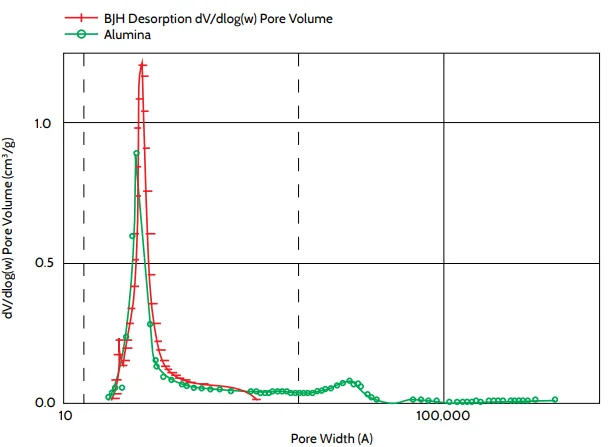

- BJH Adsorption and Desorption

- Dollimore-Heal Adsorption and Desorption

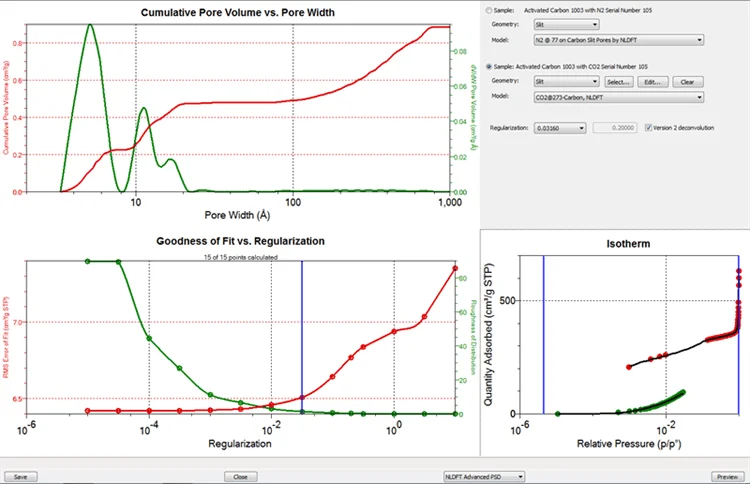

NLDFT Dual Isotherm Deconvolution and Pore Size Distribution

The NLDFT Advanced PSD, Dual DFT modeling enables the user to use the information acquired from nitrogen/argon and CO2 isotherms to produce a comprehensive pore size distribution on materials (such as carbon slit pores) where molecular-sized pores are present.

When compared to traditional nitrogen analysis, the range of pore size analysis in this approach is extended to lower pore sizes. This is because CO2 can access ultra-micropores that N2 cannot access at cryogenic temperatures due to diffusion limitations.

Image Credit: Micromeritics Instrument Corporation

Using two isotherms, this sophisticated NLDFT approach allows you to calculate the pore size distribution of your sample. In this example, CO2 adsorption (green) at 77 K and N2 (red) are utilized to generate a single pore-size distribution. Users do not have to copy and paste CO2 and nitrogen distributions since both isotherms are used to generate a single distribution.

Mercury Porosimetry/Gas Adsorption Overlay

MicroActive for the 3Flex offers a useful application that allows users to overlay pore size distributions from mercury porosimetry with gas adsorption distributions. With this new import feature, users can quickly see micropore, mesopore, and macropore distributions in a single application.

Image Credit: Micromeritics Instrument Corporation

Overlay of the different pore size distributions for BJH desorption and mercury intrusion logs for alumina pellets.

3Flex Surface Characterization Analyzer - Product Overview

Video Credit: Micromeritics Instrument Corporation