Sep 10 2009

Engineers from a maker of wireless metrology devices for wafer processing equipment, CyberOptics Semiconductor, will release their latest vibration-monitoring software at SEMICON Taiwan and demonstrate how it helps fab engineers predict equipment failure and identify wafer-contamination sources to improve yield and cycle time.

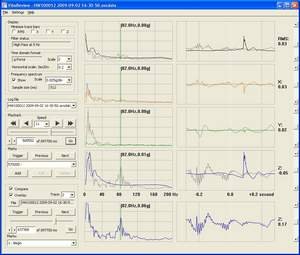

CyberOptics engineers at SEMICON Taiwan will demonstrate how fab engineers identify vibration anomalies with its latest vibration-monitoring software by filtering out acceptable acceleration offsets produced by regular slow-moving equipment or high-frequency noises between 1 to 200 Hz.

CyberOptics engineers at SEMICON Taiwan will demonstrate how fab engineers identify vibration anomalies with its latest vibration-monitoring software by filtering out acceptable acceleration offsets produced by regular slow-moving equipment or high-frequency noises between 1 to 200 Hz.

CyberOptics engineers at SEMICON Taiwan will demonstrate how fab engineers identify vibration anomalies by filtering out acceptable acceleration offsets produced by regular slow-moving equipment or high-frequency noises between 1 to 200 Hz, according to Craig C. Ramsey, Ph.D., CyberOptics Semiconductor's general manager and CTO.

Ramsey said engineers are able to set low, high or band-pass filters of equipment vibration frequencies with the company's latest vibration-monitoring software. Engineers may, for instance, filter out vibrations of 20 Hz and below and monitor vibrations of 21 Hz and above.

The software gives engineers the ability to troubleshoot and conduct preventative maintenance (PM) for vibration-related contamination and downtime "more efficiently and accurately by accounting for the natural environment of each process and existing controls," Ramsey said.

"When you know the relationship between equipment and tools in a process, you can really begin to optimize for acceleration and vibration," Ramsey said. "Our team in Taiwan will walk engineers through vibration monitoring and how the data applies to the floor."

Ramsey added that CyberOptics' new AVS 1.6 for the WaferSense® Auto Vibration System (AVS) helps engineers "quickly contrast" vibration by equipment, run time and technician to set process controls. The software allows engineers to generate an overview CSV file in Excel that contains a color-coded summary table of peak accelerations and vibration excursion across multiple data log files.

Fab engineers analyze more narrow data with the software by comparing two waveforms from different data logs. Engineers lay a second log-file trace for time domain and frequency domain over the main trace. Users can also export a portion of a single data log to a CSV file, as well as an entire data log.

Engineers have the ability to select from one of three units of measurement when using the software: g-Force, GAL (acceleration in cm/s2) -- or Energy (g2sec), which is a "good indicator of how much vibration a piece of equipment experiences in a given period," Ramsey said.

CyberOptics' AVS is a wireless, wafer-like device that allows engineers to establish yield-based vibration standards for equipment and technicians, identify vibration sources and set acceptable acceleration parameters for equipment.

CyberOptics Semiconductor will demonstrate its set of vibration-monitoring applications, VibeView™ and VibeReview™, and its entire line of WaferSense metrology devices at SEMICON Taiwan at booth 908 with its distribution partner, Taiwan Puritic Corp. (TPC).

For more details on the software and download instructions, visit http://www.cyberopticssemi.com/downloads/wafersense/avs/

The WaferSense family of devices includes the Airborne Particle Sensor (APS), Auto Leveling System (ALS2 Vertical), Auto Teaching System (ATS) and Auto Gapping System (AGS). Each device follows the processing life of a wafer and reports real-time metrology data.