A synthetic nanocomposite material, that becomes stronger under continued stress, has been developed by scientists. The work has been performed at the Rice University lab of a chemist and a professor in materials science and mechanical engineering, Pulickel Ajayan.

This recent work shows the possibility of strengthening the polymer-based nanocomposites using carbon nanotube fillers.

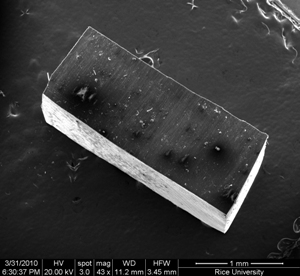

A small block of nanocomposite material proved its ability to stiffen under strain at a Rice University laboratory.

A small block of nanocomposite material proved its ability to stiffen under strain at a Rice University laboratory.

A graduate student at Rice University lab, Brent Carey, has created a composite using polydimethylsiloxane (PDMS), a rubbery polymer, and a group of multiwalled nanotubes that are vertically aligned. While testing the fatigue properties of the composite, Carey has discovered an exciting property. He found that the composite material were not damaged even after repeated stress and the stress stiffened the material.

He utilized the dynamic mechanical analysis (DMA) for testing the polymer-based composites and the results have been surprising. The test shows that there has been a 12% increase in the stiffness of the material after applying 3.5 million compressions over a week. Hence, the use of nanomaterials-based composites boosts the interfacial effects when compared to conventional composites. Another important fact that has been found by the researchers is that simple loding does not change the properties of a material. It is only the dynamic stress that strengthens the nanocomposites.

Thus, the Rice researchers’ work shows the efficient use of nanomaterials as fillers in composites. This new research results will help to understand how carbon nanotubes and polymer work together at the nanoscale.

Source: http://media.rice.edu/