A collaborative research between Physicists at University of Texas at Austin and researchers from China and Taiwan has yielded the world’s smallest semiconductor laser. This is touted as a significant progress in the emerging field of photonic technology with implications for applications ranging from medicine to communication to computing.

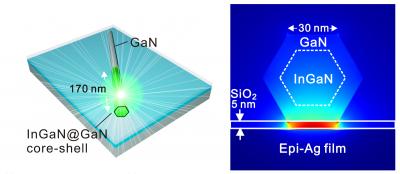

This is an illustration of the nanoscale semiconductor structure used for demonstrating the ultra-low-threshold nanolaser. A single nanorod is placed on a thin silver film (28 nm thick). The resonant electromagnetic field is concentrated at the 5-nm-thick silicon dioxide gap layer sandwiched by the semiconductor nanorod and the atomically smooth silver film. Credit: copyright Science

The challenge in the development of small, fast and low energy photonic technologies such as ultra sensitive, disease detecting biosensors, ultrafast computer chips and new generation of communication technologies is in scaling down the size of semiconductor lasers. Photonic devices that employ nano lasers to transmit information by generating optical signals can easily replace electronic circuits. A factor that has impeded the size and performance of photonic devices is the three-dimensional diffraction limit.

The nano laser developed by the University of Texas team operates below the three-dimensional diffraction limit. It is a continuous wave laser that emits a green light when triggered. The laser cannot be seen with the naked eye and is made of a gallium nitride nanorod partly filled with indium gallium nitride. The nanorods are placed above a thin layer of silicon which in turn lies above an atomically smooth silver film. The alloys used in the nanorods are those commonly employed in LEDs.

The atomically smooth film is the result of 15 years of work by the team. Atomically smooth photonic devices restrict data loss as they do not scatter plasmons, which are electron waves transmitting data. Nano lasers could lead the way for on-chip communication systems, thereby eliminating information loss and heat gain associated with multi-chip systems.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.