May 16 2014

Engineers use silicon dioxide to make lithium-ion batteries that last three times longer between charges compared to current standard

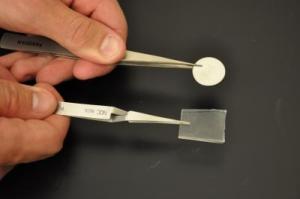

This is the silicon polymer and battery used for the research. (Credit: UC Riverside)

This is the silicon polymer and battery used for the research. (Credit: UC Riverside)

Using a material found in Silly Putty and surgical tubing, a group of researchers at the University of California, Riverside Bourns College of Engineering have developed a new way to make lithium-ion batteries that will last three times longer between charges compared to the current industry standard.

The team created silicon dioxide (SiO2) nanotube anodes for lithium-ion batteries and found they had over three times as much energy storage capacity as the carbon-based anodes currently being used. This has significant implications for industries including electronics and electric vehicles, which are always trying to squeeze longer discharges out of batteries.

"We are taking the same material used in kids' toys and medical devices and even fast food and using it to create next generation battery materials," said Zachary Favors, the lead author of a just-published paper on the research.

The paper, "Stable Cycling of SiO2 Nanotubes as High-Performance Anodes for Lithium-Ion Batteries," was published online in the journal Nature Scientific Reports.

It was co-authored by Cengiz S. Ozkan, a mechanical engineering professor, Mihrimah Ozkan, an electrical engineering professor, and several of their current and former graduate students: Wei Wang, Hamed Hosseinni Bay, Aaron George and Favors.

The team originally focused on silicon dioxide because it is an extremely abundant compound, environmentally friendly, non-toxic, and found in many other products.

Silicon dioxide has previously been used as an anode material in lithium ion batteries, but the ability to synthesize the material into highly uniform exotic nanostructures with high energy density and long cycle life has been limited.

There key finding was that the silicon dioxide nanotubes are extremely stable in batteries, which is important because it means a longer lifespan. Specifically, SiO2 nanotube anodes were cycled 100 times without any loss in energy storage capability and the authors are highly confident that they could be cycled hundreds more times.

The researchers are now focused on developed methods to scale up production of the SiO2 nanotubes in hopes they could become a commercially viable product.