Researchers from the University of Delaware and the Chinese Academy of Sciences have successfully used nanotechnology to create a real “flux capacitor”.

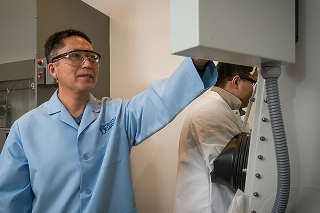

UD's Bingqing Wei is part of a research team that has reported on the use of nanotechnology to improve the energy density of dielectric capacitors.

UD's Bingqing Wei is part of a research team that has reported on the use of nanotechnology to improve the energy density of dielectric capacitors.

The flux capacitor is mainly known as a device from science fiction, but capacitors have become vital components in computing systems, electric vehicles, and portable electronics. High storage capacity is a key advantage of batteries, but they can offer only slow energy delivery.

Conversely, capacictors offer rapid delivery of energy, but suffer from inferior storage capacity. This characteristic is referred to as energy density, and has been the subject of much research.

The dielectric capacitor consists of an insulating material placed between two conducting metal plates.

The paper, titled “Dielectric Capacitors with Three-Dimensional Nanoscale Interdigital Electrodes for Energy Storage”, discusses the research findings in the online-only journal of AAAS, Science Advances.

“With our approach, we achieved an energy density of about two watts per kilogram, which is significantly higher than that of other dielectric capacitor structures reported in the literature,” says Bingqing Wei, professor of mechanical engineering at UD.

“To our knowledge, this is the first time that 3D nanoscale interdigital electrodes have been realized in practice,” he adds. “With their high surface area relative to their size, carbon nanotubes embedded in uniquely designed and structured 3D architectures have enabled us to address the low ability of dielectric capacitors to store energy.”

An interdigitated design is one of the key success factors of this novel capacitor. It resembles interwoven fingers between two hands wearing “gloves”. This design helps reduce the distance between opposite electrodes considerably, thereby enhancing the capacitor’s ability for electrical charge storage.

Another innovative design feature of the new capacitor is the 3D nanoscale electrode, which offers high voltage breakdown. As a result, the integrated dielectric material, such as alumina, can reliably perform its intended purpose as an insulator.

“In contrast to previous versions, we expect our newly structured dielectric capacitors to be more suitable for field applications that require high energy density storage, such as accessory power supply and hybrid power systems,” Wei says.