May 26 2021

The ultrathin material graphene is defined by its extremely small bending modulus—superflimsiness.

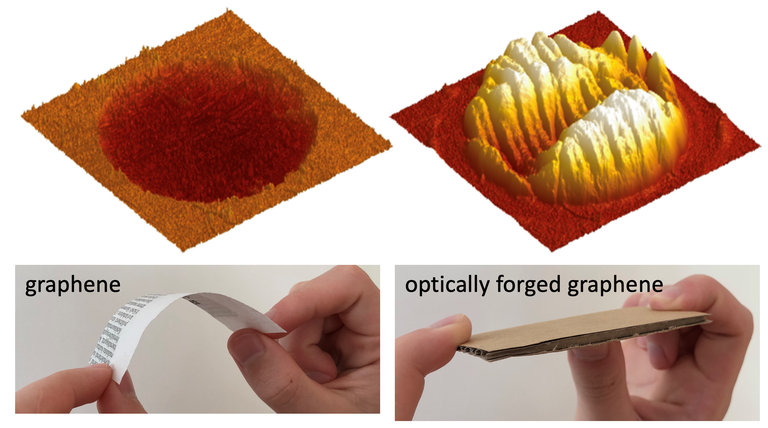

Top: Atomic force microscopy images of the suspended graphene drum skin before and after optical forging. Below: analog presentation of how a material can become stiffer when it is corrugated. Image Credit: University of Jyväskylä/Pekka Koskinen, Vesa-Matti Hiltunen.

Top: Atomic force microscopy images of the suspended graphene drum skin before and after optical forging. Below: analog presentation of how a material can become stiffer when it is corrugated. Image Credit: University of Jyväskylä/Pekka Koskinen, Vesa-Matti Hiltunen.

Scientists from the Nanoscience Center of the University of Jyväskylä have now demonstrated that a new experimental method, known as optical forging, can make graphene extremely stiff and boost its stiffness by many orders of magnitude. The study was published in the npj 2D Materials and Applications journal in May 2021.

Graphene—an atomically thin carbon material—has exceptional properties, like high optical transparency, excellent thermal conductivity and large charge carrier mobility.

The tensile strength and impermeability of graphene are 200 times that of steel, making it well-suited for nanomechanical applications. But regrettably, the exceptional flimsiness of graphene makes any 3D structures notoriously hard and unstable to fabricate.

But now these challenges may be over because a team of researchers from the Nanoscience Center of the University of Jyväskylä has revealed how graphene can be made extremely stiff by using an exclusively designed laser treatment. This stiffening process paves the way to whole new application fields for graphene.

Previously, the same team of researchers had prepared 3D graphene structures with the help of a pulsed femtosecond laser patterning technique, known as optical forging. This laser irradiation creates defects in the graphene lattice, which consequently extends the lattice and results in stable 3D structures.

In this case, the researchers applied optical forging to alter a monolayer graphene membrane, which was suspended similar to a drum skin, and then quantified its mechanical characteristics through nanoindentation.

The measurements showed that graphene had increased bending stiffness by up to five orders of magnitude when compared to pristine graphene, which is actually a new world record.

At first, we did not even comprehend our results. It took time to digest what optical forging had actually done for graphene. However, gradually the full gravity of the implications started to dawn on us.

Dr. Andreas Johansson, University of Jyväskylä

Dr Johansson headed the study on defining the characteristics of the optically forged graphene.

Stiffened Graphene Opens up Avenues for Novel Applications

The study showed that increased bending stiffness was the outcome of optical forging by strain-engineering corrugations in the graphene layer.

As part of the analysis, the team carried out thin-sheet elasticity modeling of the corrugated graphene membranes and demonstrated that the stiffening occurs on both the nanoscales and microscales at the level of the induced flaws in the graphene lattice.

The overall mechanism is clear but unraveling the full atomistic details of defect-making still needs further research.

Pekka Koskinen, Professor, University of Jyväskylä

The modeling was performed by Professor Koskinen.

Stiffened graphene paves the way for many innovative applications, like leveraging the mechanical resonance frequency of graphene membrane resonators up to the GHz regime or fabricating microelectromechanical scaffold structures.

Since graphene is impermeable, strong and lightweight, one possibility is to apply optical forging to graphene flakes to create micrometer-scale cage structures for transporting drugs intravenously.

The optical forging method is particularly powerful because it allows direct writing of stiffened graphene features precisely at the locations where you want them.

Mika Pettersson, Professor, University of Jyväskylä

Professor Pettersson has supervised the development of the latest method.

“Our next step will be to stretch our imagination, play around with optical forging, and see what graphene devices we can make,” concluded Professor Pettersson.

Journal Reference:

Hiltunen, V.-M., et al. (2021) Ultrastiff graphene. npj 2D Materials and Applications. doi.org/10.1038/s41699-021-00232-1.