An article published in the journal Forests highlights improved quasistatic Berkovich nanoindentation methods for improving measurement accuracy in complicated polymeric materials like wood cell walls.

Study: Best Practices for Quasistatic Berkovich Nanoindentation of Wood Cell Walls. Image Credit: Digital Photo/Shutterstock.com

Traditional methods presume that specimens are rigidly supported, homogenous, and semi-infinite. However, for accurate results, newly-improved quasistatic Berkovich nanoindentation is desirable as it provides a way to correct and detect errors related to surface detection and structural compliances emerging from dirty probes, nanoindenter performance, and displacement drift.

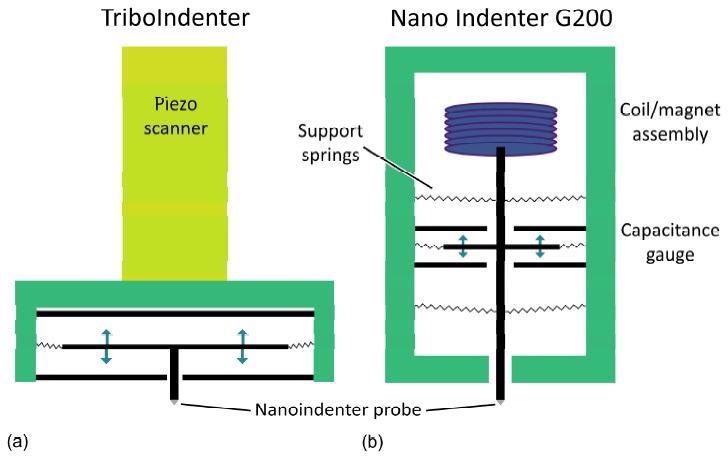

Two example designs of transducers used in commercial nanoindenters. (a) The standard transducer of Bruker’s Hysitron (Minneapolis, MN, USA) TriboIndenter is a three-plate capacitive force/displacement transducer. The probe is attached to the center plate, which is suspended between the two outer plates by leaf springs. To measure displacement, an AC signal 180_ out of phase is applied to the two outer plates, creating an electric field potential between the two outer plates that is zero in the center. The voltage measured from the middle plate is calibrated to measure displacement. Force is applied to the center plate by applying a large DC offset to the bottom or top plate, which creates an electrostatic attraction with the center plate that can be calibrated as a force. The transducer is attached to a piezo scanner, which allows the nanoindenter probe to also be used as an imaging stylus. (b) The KLA-Tencor Corporation (Milpitas, CA, USA) Nano Indenter G200 uses an electromagnetic force transducer and capacitance gauge to measure displacement. The probe assembly is also supported by leaf springs. Image Credit: Jakes, J. E., & Stone, D. S.

From Traditional to Improved Nanoindentation

Performing fused silica calibration trials to calculate the nanoindenter machine compliance and probe area function is a common part of traditional nanoindentation study. These calibrations are then utilized to calculate hardness and elastic modulus by analyzing the load–depth trace of the test material.

The key to improvements is to determine multi load nanoindentations, in which mechanical characteristics are assessed as a function of nanoindentation size at each nanoindentation point.

A substitute for improvisation can be to rely on Continuous Stiffness Measurements (CSM), but additional efforts are required to make CSM reliable.

Nanoindentation Basics

One of the basics includes instrumentation to determine load and displacements separately, an actuation mechanism to perform a predefined loading function, and the capacity to precisely pinpoint nanoindentation in the specimen.

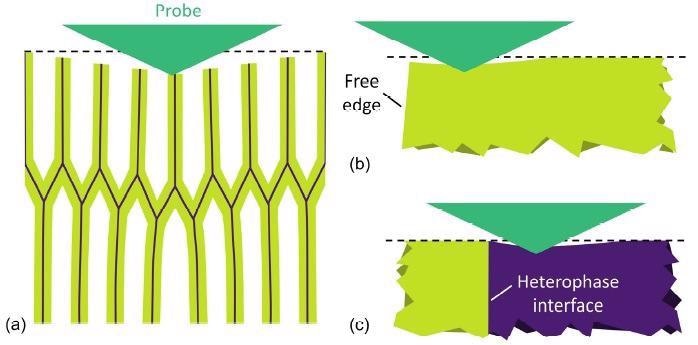

Moreover, basic contact mechanics and load-depth trace are analyzed to determine elastic properties such as Young’s Modulus of Wood. In addition, the structural compliance Cs method is applied to study outcomes on nanoindentation of specimen-scale flexing nearby edges.

Multiload nanoindentations are performed to evaluate accurate Cs. Furthermore, to acquire load (P) and depth (h) as precisely as feasible, the user must construct pre-nanoindentation load functions and experimental techniques. It is also necessary to select a wood specimen that is entirely flat, clean, and placed perpendicular to the direction that the nanoindentation probe is pressed into the material.

Schematics illustrating potential sources of structural compliances in wood cell wall nanoindentation, including (a) specimen-scale flexing represented by deformations in the wood cellular structure, (b) a free edge, such as with an empty lumen, and (c) a heterophase interface, such as between the CCML and S1 secondary cell wall. Image Credit: Jakes, J. E., & Stone, D. S.

Materials and Methods

The specimen, latewood loblolly pine, is prepared under ambient conditions. During the studies, the temperature is not actively regulated and fluctuated between 24 and 26 degrees Celsius. Moreover, residual indents are captured with Atomic Force Microscope (AFM) in contact mode using Advance Surface Microscopy.

Analysis Algorithm

To assure the process order, an analysis algorithm is necessary to perform that allows data to be discarded or to be improved by making modifications.

Firstly, fused silica calibrations are performed to determine the Cm, probe area function, and Berkovich probe tip imperfections. Secondly, images of the residual nanoindentation impressions are used to verify the placement and quality of the nanoindentation. Nanoindenter probe Scanning Probe Microscopy (SPM) or AFM are commonly used to obtain these pictures.

Thirdly, a preliminary load-depth trace is checked to identify anomalous behavior of the results obtained. If only a tiny percentage of the nanoindentations in a data set behave abnormally, they should be removed before the analysis method continues.

Afterward, pre-nanoindentations liftoff analysis is performed to detect dirty probe tips. In the next step, Displacement drift is measured and corrected. Then a preliminary analysis is performed to study if any unloading segments match to nanoindentations with nanoindentation diameter, Ao ½ > 0.266 µm. Finally, surface errors are detected, and then results are compared to independent area measurements.

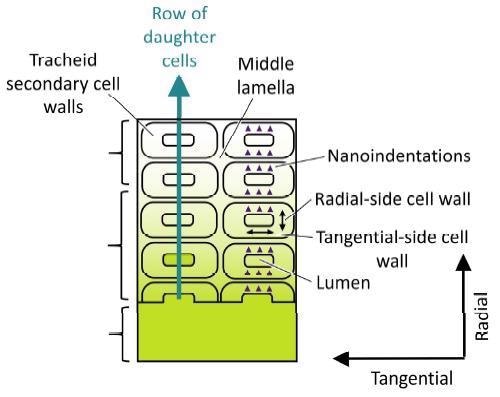

Schematic illustrating how to design an experiment taking advantage of a row of daughter cells to study the effects of treatment, such as an adhesive or coating, on cell wall properties with a high amount of sensitivity. Image Credit: Jakes, J. E., & Stone, D. S.

Results of the Study

To highlight the main results of this study, only nanoindentations having at least three unloading segments that matched the size criterion were initially included. Moreover, the constant characteristics for Ao ½ > 0.266 µm also indicated that structural compliances had been adequately accounted for and that no significant depth surface detection mistake had occurred.

Lastly, the most important result was that properties do not depend on nanoindentation size Ao ½ > 0.266 µm. In improvements, it was advised to run a single experiment for all treatments and include as much information as possible in the data.

Nanoindentation - A Valuable Tool

Nanoindentation has proven to be an effective method for determining the mechanical characteristics of complicated micrometer-scale materials like wood cell walls. The accuracy of quasistatic Berkovich hardness and elastic modulus measurements in complicated materials, such as wood cell walls, was improved using nanoindentation techniques and an analysis program proposed in this research.

Continue reading: https://www.azonano.com/article.aspx?ArticleID=5890.

Further Reading

Jakes, J. E., & Stone, D. S. (2021) Best Practices for Quasistatic Berkovich Nanoindentation of Wood Cell Walls. Forests, 12(12). Available at: https://www.mdpi.com/1999-4907/12/12/1696

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.