In a paper published in the journal Langmuir, a cogent analysis of the innate physioelectrochemical qualities of flexible electrodes developed from conductive papers based on carbon allotropes, including conducting papers of graphene (GR), carbon nanotubes (CNTs), and carbon fiber (CF), is presented.

Study: Evaluation on the Intrinsic Physicoelectrochemical Attributes and Engineering of Micro-, Nano-, and 2D-Structured Allotropic Carbon-Based Papers for Flexible Electronics. Image Credit: Shawn Hempel/

Shutterstock.com

The Rise of Flexible Electronics

Flexible technology is gaining popularity for new electronic equipment including, sensors, batteries, and bioimaging devices, due to its beneficial qualities such as slenderness, minimal weight, flexibility, and cheap cost.The emergence of different kinds of carbon allotrope-based conductive papers opened up a new dry process fabrication route for the production of wearable and pliable devices. The predominant morphological characteristics and micro-structured or nanostructured facets of the carbon-based papers have a significant impact on electrochemical characteristics and flexure stability.

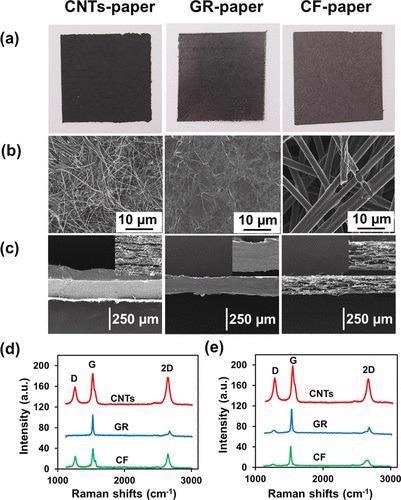

(a) Photographs of CNTs-paper, GR-paper, and CF-paper. (b) Top view and (c) cross-sectional view of SEM images for CNTs-paper, GR-paper, and CF-papers. (c) Inset shows high magnification. (d) Raman spectra of original allotropic carbon papers CNTs-paper (red line), GR-paper (blue line), and CF-paper (green line). (e) Raman spectra of allotropic carbon papers CNTs-paper (red line), GR-paper (blue line), and CF-paper (green line) after pretreatment with isopropanol, plasma, and isopropanol, respectively. Image Credit: Kongkaew, S., et al

Fabrication Techniques

The manufacturing specifics of pliable electrodes are significant among the components of flexible technology. Existing approaches for fabricating pliable electrodes can be divided into two categories: "bottom-up" technique i.e., wet chemistry on the basis of depositing a conductive layer onto a pliable substrate or printing precursory conductive inks, and the “top-down" technique based on forming a predeveloped conductive bulk flexible substrate into anodes and cathodes.

The bottom-up technique based on imprinting conductive dyes may present a few drawbacks, including the thorough utilization of solvents for dye preparation, the need for a supplementary screen, mask, or stencil to design the conductive dyes, as well as a well-heated dye curing procedure. In contrast, vapor evaporation strategies involve costly equipment for manufacturing flexible electrodes.

The top-down strategy utilizing a predeveloped flexible conductive substrate manufactured on a grand scale via the assembly of nanoscale or microscale components into a macroscale papery substrate opens up a new avenue for the simple manufacture of sophisticated flexible electronic equipment.

Bending stability test evaluated by 1/Csp with repeated bending cycles and corresponding SEM images in high magnification after 300 cycles bending for (a) CNTs-paper-, (b) GR-paper-, and (c) CF-paper-based flexible electrodes. (a) Inset shows the bending angle. SEM image in low magnification at bending position for (d) CNTs-paper, (e) GR-paper, and (f) CF-paper after repeated 300 bending cycles. Image Credit: Kongkaew, S., et al

Incorporation of Allotropes

The electrolytic performance of electrical or bioelectronic equipment has been greatly improved as a result of the use of sophisticated allotropes such as diverse types of metallic nanoparticles (NPs); nanostructured 2D-structured materials based on carbon; and nanostructured conductive polymers.

Materials based on carbon (for example, graphite, carbon fiber, and glassy carbon) are the most often used electrode components. Ordinary carbon offers several advantages, including strong thermal and electric conduction, chemical stability, cytocompatibility, a large operating window, and minimal background current.

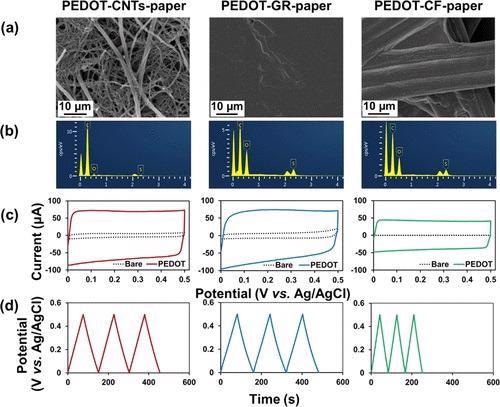

Sophisticated nanostructured carbon allotropes such as CNTs and GR with better conductance, quicker charge-transfer rate, and increased specific area with superior electrode characteristics are intriguing materials for upcoming electronic equipment. The electrodes of sophisticated electrical equipment must be modified with synthetic catalysts or polymeric organic conductors. Prussian blue (PB) and poly(3,4-ethylenedioxythiophene) (PEDOT) were combined with electrodes of carbon allotropes, resulting in better conductance, capacitance, and electrolytic sensory capabilities.

Flexible Electrodes based on Carbon Papers

Considerable effort has been dedicated to the innovation of carbon allotrope papers with low weight and pliability, like carbon fiber (CF), carbon nanotubes (CNTs), and graphene (GR) based papers, as motivated by the evolving conducting paper industry.

The use of these predeveloped conductive sheets eliminates the need for wet chemistry or an extra stencil for print and well-heated curing operations, while the production of the pliable electrode is accomplished by straightforward xurography and paper assembly.

An understanding of the innate nanoscale or microscale qualities of CNTs, GT, and CF within the assembled bulk conductive sheets, such as morphology, chemical properties, and faults arising from nanostructured or micro-structured carbon allotropes, along with flexure stability, electrolytic properties, and post catalytic modification, for the creation of sophisticated flexible electrodes based on carbon papers.

(a) SEM images and (b) EDX spectra of PEDOT-CNTs-paper, PEDOT-GR-paper, and PEDOT-CF-paper. (c) Cyclic voltammograms of CNTs-paper, GR-paper, and CF-paper in 0.1 M KCl solution before and after modification of PEDOT at a scan rate of 0.05 V s–1. (d) Galvanostatic charge–discharge curves of PEDOT-CNTs-paper, PEDOT-GR-paper, and PEDOT-CF-paper in 0.1 M KCl solution. Image Credit: Kongkaew, S., et al

Research Findings

All of the allotropic carbon sheets demonstrated an excellent characteristic G band matching to the in-plane vibrations of SP2 bonded carbon, which is required for a conductive electrode foundation.

When compared to the micro-structured CF-paper electrode, the nanostructured CNTs- and GR-paper electrodes demonstrated quicker electrode kinetics. Bending stabilities of CNTs- and GR-paper electrodes constructed of nanostructured carbon demonstrated increased stability, enabled by the nano-dimensional characteristic of the combined CNTs and GR for superior resistance to structural fracture during bending. Researchers also showed how to functionalize allotropic carbon papers using an inorganic catalyst to make PB-carbon-paper for electrochemical sensing and an organic conducting polymer to make PEDOT-carbon-paper for energy storage. Despite the fact that CNTs- and GR-papers are more expensive than CF-papers, their superior electrochemical performance and bending stability are critical for the development of improved flexible and wearable electronics.

Continue reading: How Can Printable Silicon Nanocomposites Improve Metalenses?.

Further Reading

Kongkaew, S., Meng, L., Limbut, W., Kanatharana, P., Thavarungkul, P., & Mak, W. C. (2021). Evaluation on the Intrinsic Physicoelectrochemical Attributes and Engineering of Micro-, Nano-, and 2D-Structured Allotropic Carbon-Based Papers for Flexible Electronics. Langmuir. Available at: https://doi.org/10.1021/acs.langmuir.1c02121

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.