In a research paper published in Nano Energy, a group of researchers reported that when a platinum-plated atomic force microscope tip is pushed over a pristine doped silicon substrate, an extremely thin silicon oxide layer is formed.

Study: Current degradation mechanism of tip contact metal-silicon Schottky nanogenerator. Image Credit: sanjaya viraj bandara/Shutterstock.com

The transfer of electrons across the tip touched surface transforms from a contact surface to a tribo-tunneling method when the number of slides over the same region increases. Furthermore, current deterioration may be reduced when the pristine silicon substrate is heated with nitrogen. Their research not only adds to our knowledge of the electron transfer mechanism in active Schottky connections but also points to a path for future junction optimization for steady current production.

Miniaturization of Electronic Devices

Electronic equipment can be simplified to decrease their imprints, energy consumption, and transmission time consumption for a wide range of applications, including sensing devices for the Internet of Things (IoT), portable versatile electronic parts for healthcare monitoring devices, and so on, thanks to advances in nanoscience and microelectromechanical systems (MEMS) technology.

Till now, the majority of these devices have relied on external sources of power such as energy storage devices, which have a finite lifespan. Having a reliable power supply for such electronic gadgets is critical to increasing their application. As a result, small portable energy collectors are seen to be a viable option. Several forms of micro/nano electric generators, such as electrostatic generators, electromagnetic generators (EENG), plyometric generators (PENG), and thermoelectric generators (TENG), have been proven for this purpose.

Working Process of Traditional TENGs

Electrostatic voltage and eventually contact electrification are used to operate classic TENGs. Regular directional contact-separation action of two electrodes with considerably varying electron affinities generates alternating current (AC). Anodes must be insulated. Although a converter bridge in the open circuit may convert produced AC to direct current (DC), the inverters waste electric energy, resulting in low energy conversion and poor mobility.

Due to the tribo-voltaic interaction, a DC was generated by moving a metallic AFM tip on the MoS2 substrate.

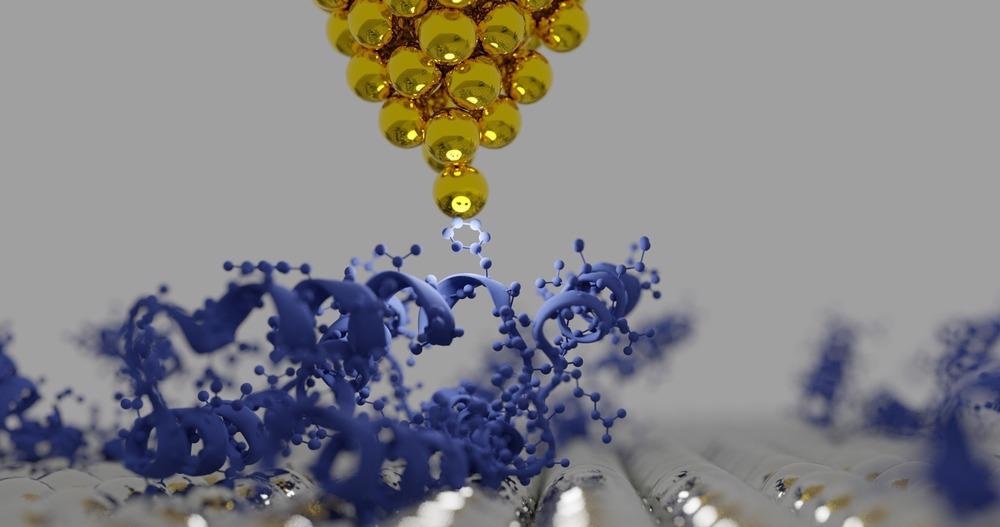

Sliding a Platinum-Coated AFM Tip Over Doped Silicon Substrates

The researchers examined how current is generated when a Pt-coated AFM tip is pushed over-doped silicon surfaces.

With a conducting AFM, the current production across the same and various sliding surfaces is examined systematically (C-AFM). They discovered that when the AFM tip is pushed over the same location repeatedly, the produced current decreases dramatically as the frequency of sliding cycles increases.

While the tip slides across the substrate, an extremely thin silicon oxide layer forms, most likely due to degradation of the silicon substrate action of electric force between the tip and the surface. When the AFM tip was continuously swept over the same region, the produced DC current reduced dramatically.

The total current in the initial scan over a freshly cleaned surface seemed to be larger than in successive current mapping over the same region. Interestingly, when researchers took the scans over another freshly cleaned surface area without altering the tip, a set of comparable current tracing was acquired. This data demonstrated that AFM tip wear and tear did not affect the deterioration of the produced DC. Instead, it might be the consequence of changes in the silicon surface characteristics caused by AFM tip scanning.

Annealed Silicon Substrates in Nitrogen Environment

The researchers investigated the effect of an ultra-thin coating of silicon oxide on output flux density by annealing two samples of freshly cleaned silicon substrates at 150 °C for one hour. During air annealing, an ultra-thin silicon oxide layer developed on the substrate.

Nitrogen annealed sample, on the other hand, did not stimulate the formation of a silicon oxide film. In contrast to the cleaned surface, the silicon annealed in nitrogen exhibited a small drop in current density.

The researchers also scanned the nitrogen annealed silicon substrate to evaluate the effect of nitrogen annealing on current output. The current output from the nitrogen annealed surface exhibited less deterioration than those scanned in air.

Research Findings and Conclusion

The researchers examined how the flux density generated by sweeping (or moving) a Pt-plated AFM tip over silicon substrate surfaces deteriorated. The average current acquired by current tracing was found to be substantially lower when the frequency of tip swept over the same region was increased.

The decrease of DC current is caused by the formation of an ultrathin silicon oxide layer between the probe tip and the silicon substrate, which is induced by the generated electric field and water molecule adsorption. It was also revealed that annealing the treated silicon substrate in a nitrogen environment reduced the degradation process.

Continue reading: Using AFM for Nanostructure Analysis.

Reference

Deng, S. et al. (2021). Current degradation mechanism of tip contact metal-silicon Schottky nanogenerator. Nano Energy. Available at: https://www.sciencedirect.com/science/article/abs/pii/S221128552101137X

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.