In a study published in the journal Nanomaterials, a novel technique on the basis of the fluidized bed chemical vapor deposition (FBCVD) method was developed to produce three-dimensional graphene networks (3D GNs) with diverse nanostructures.

Study: Mass Production of 3D Connective Graphene Networks by Fluidized Bed Chemical Vapor Deposition and Its Application in High Performance Lithium-Sulfur Battery. Image Credit: Rost9/Shutterstock.com

3D Graphene

Graphene has been extensively researched because of its unique and exceptional features, including a large specific area, good electric conductance and charge transport, good heat conduction, strong mechanical performance, superior pliability, and effective light absorbance. Its usage in battery packs, electrochemical capacitance, catalysts, storing hydrogen, environmental decontamination, and sensing applications have been extensively researched.

On the other hand, isolated graphene films frequently experience permanent aggregation because of the significant van der Waals forces and considerable inter-film junction contact resistance. To minimize graphene sheet restacking, 2D graphene is often formed into 3D frameworks with organized architectures.

3D graphene retains the bulk characteristics of 2D graphene and improves its use for real-world applications. Graphene research has grown significantly in the realm of electrochemical energy storage.

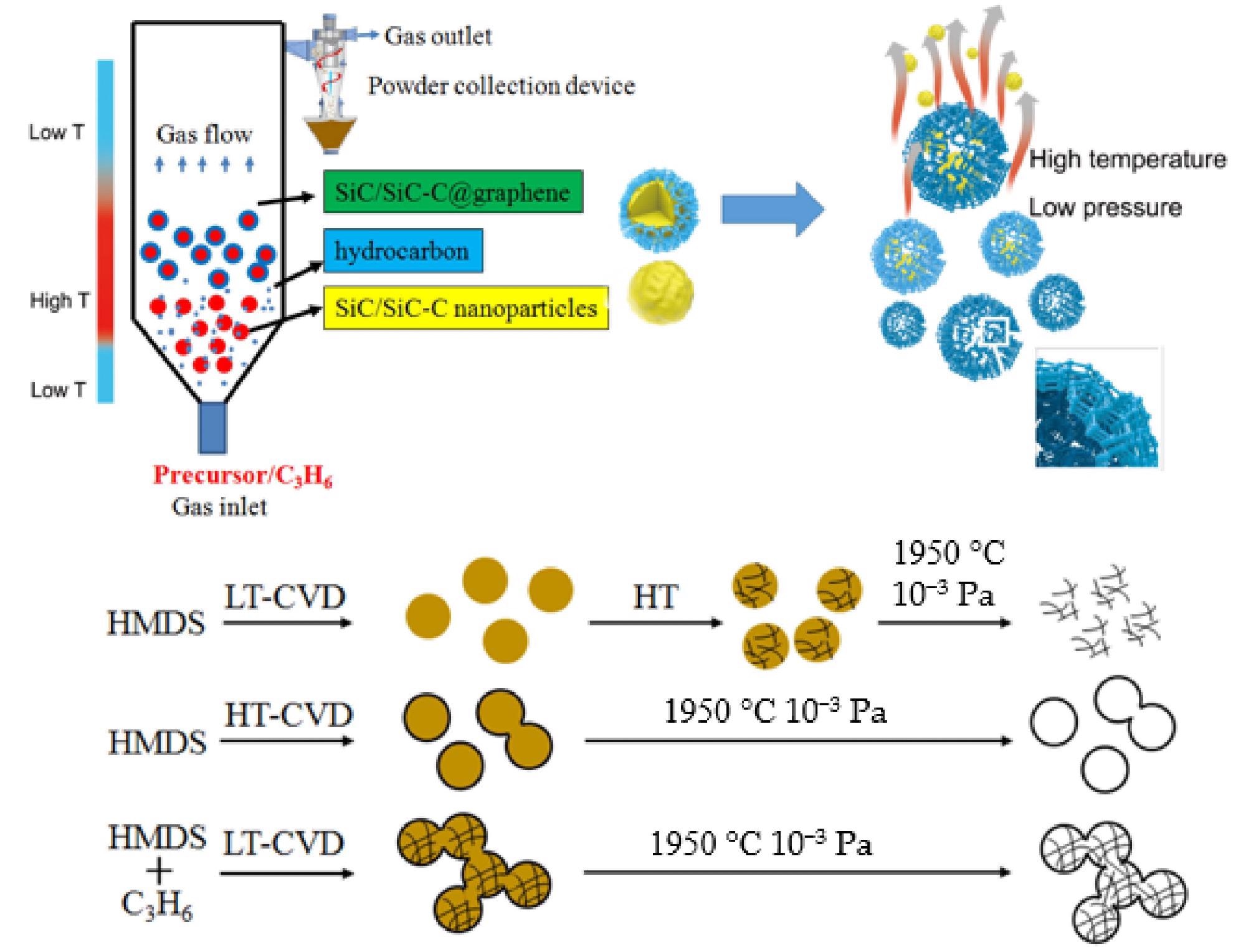

Schematic diagram of the preparation process for the 3DGNs by fluidized bed chemical vapor deposition combined with subsequent heat treatment. © Liu, R., Zhao, J. et al. (2022).

Optimizing Lithium-Sulfur Batteries

As sulfur in elemental form has the largest hypothetical capacity of any cathode material, lithium–sulfur batteries are currently undergoing a significant amount of investigation. However, because of the inherent insulating sulfur/lithium sulfides and breakdown of intermediary polysulfide entities for irreversible loss, Li-S batteries continue to have poor cycle life and rate performance.

Furthermore, strong mechanical qualities are needed to withstand the volumetric growth of sulfur while discharging. Significant effort has been made to create cathodic materials with mesoporous and robust morphologies to produce cathodes capable of effectively transporting charged particles to sulfur, retaining the soluble polysulfides, and mitigating volumetric expansion of the cathode.

Owing to its remarkable electrical conductance, excellent mechanical performance, and capability to stop polysulfide dissolution, 3D graphene networks (3DGNs) have considerable promise as cathode materials for Li-S batteries.

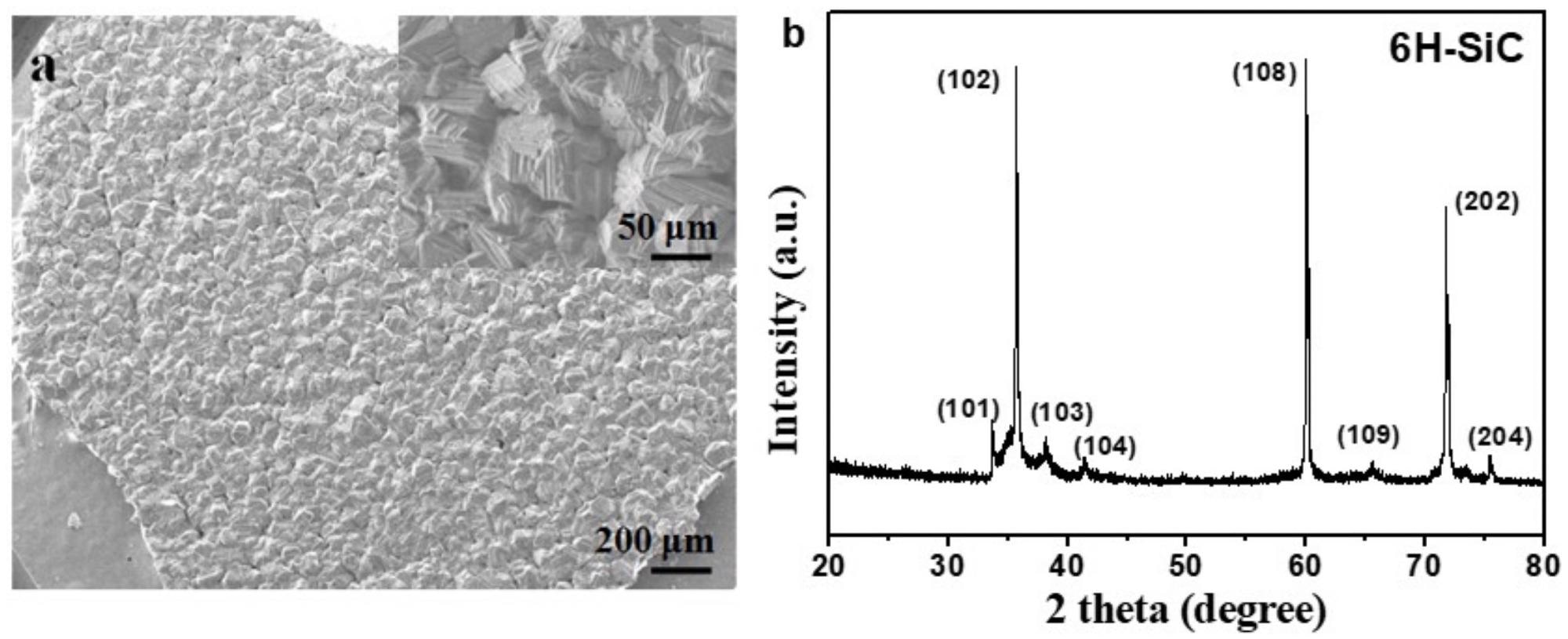

(a) SEMimages and (b) XRD pattern of the deposited SiC product on the graphite crucible cover. © Liu, R., Zhao, J. et al. (2022).

Fabrication of 3D Graphene Networks

Numerous techniques for synthesizing 3DGNs have hitherto been established, which may be split into two subgroups: graphene sheet assembly and direct fabrication from sources of carbon.

Assembly of graphene sheets is typically done in the liquid state. Owing to the high solubility afforded by the involvement of hydrophiles, graphene is utilized in the form of graphene oxide (GO).

Graphene sheets are created by scattering GO in a solution and then reducing GO chemically, electrochemically, or hydrothermally. These assembling procedures often produce 3DGNs made of GO or reduced GO (rGO).

Main Advantages

Significant discharging capacity, outstanding cycle performance, and good efficiency are attributed to the strong affinities of carbon and sulfur originating from the nanostructural hierarchy of 3DGNs. The connected GNs boost the conductance of the cathode, allowing the discharging capacity to be increased.

The hollow spheres' interwoven interior graphene nanoscale belts are strong enough to withstand volume changes and may also offer an optimal internal setting for electrochemical changes. The unique exterior graphene layers restrict the shuttle effect by preventing polysulfide movement to the electrolyte, which is thought to be the primary cause of degradation of efficiency and cyclic performance in Li-S batteries.

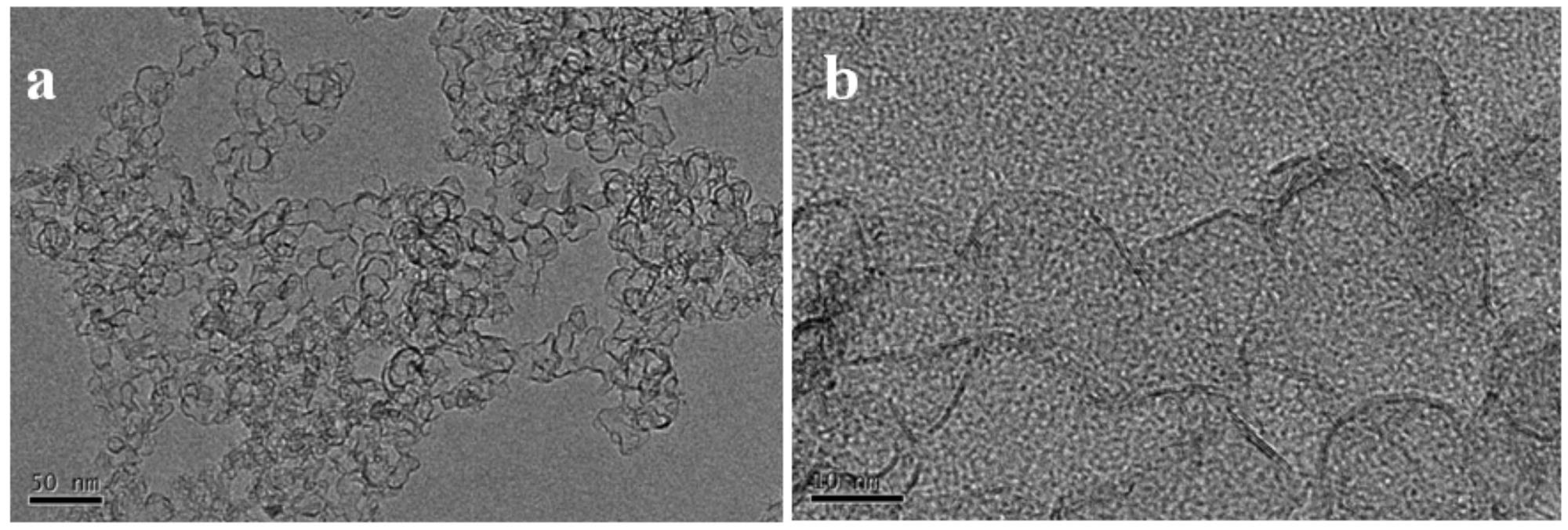

TEM images of the connective 3D graphene hollow cages obtained from the sample prepared at the FB–CVD temperature of 1300 °C under pure Ar atmosphere (sample S4). (a) Low magnification, (b) High magnification. © Liu, R., Zhao, J. et al. (2022).

Important Findings of the Study

In this study, by using the FBCVD method followed by heat treatment, 3DGNs with new nanostructures were created. Core/shell structured SiC-graphene nanoscale composites were made by utilizing the fluidized bed's irregular temperature profile and the quick transportation mechanism.

By changing the reaction environment, FBCVD precursors, and heat, 3DGNs with various nanostructures may be constructed.

SiC@graphene nanoscale composites were used to create unique 3D graphene nanoarchitectures with interwoven graphene nanobelts and linked graphene shells. The 3DGNs worked well as electrodes of Li-S batteries, exhibiting greater sulfur loading, higher discharging capacity, outstanding cycle performance, and good efficiency.

The 3DGNs' interior hierarchy and exterior microstructures enabled excellent electrochemical performance by enhancing conductance, resisting volumetric expansion, and preventing the shuttle effect.

Future Prospects

This study presents a unique and efficient synthesis technique for the creation of 3DGNs with nanoarchitectures.

Due to their precise structural design and incorporation with various functional materials, these unique 3DGNs will find wide uses in sectors such as Li-ion batteries, catalytic carriers, and supercapacitors. The FBCVD process's mass manufacturing offers up new avenues for large-scale engineering applications of 3D graphene materials.

Continue reading: How Doped Graphene Could Revolutionize Next-Gen Technologies.

Reference

Liu, R., Zhao, J. et al. (2022). Mass Production of 3D Connective Graphene Networks by Fluidized Bed Chemical Vapor Deposition and Its Application in High Performance Lithium-Sulfur Battery. Nanomaterials, 12(1). Available at: https://www.mdpi.com/2079-4991/12/1/150/htm

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.