Using the proper aspect ratios, 1D flexible perovskite nanorods or nanowires may decrease crystalline surface defects and ultimately improve the performance of devices. In a study recently published in the journal Materials Research Bulletin, electrospinning was used to create completely synthetic perovskite/polymer composite nanofibrous films suitable for perovskite solar cell applications.

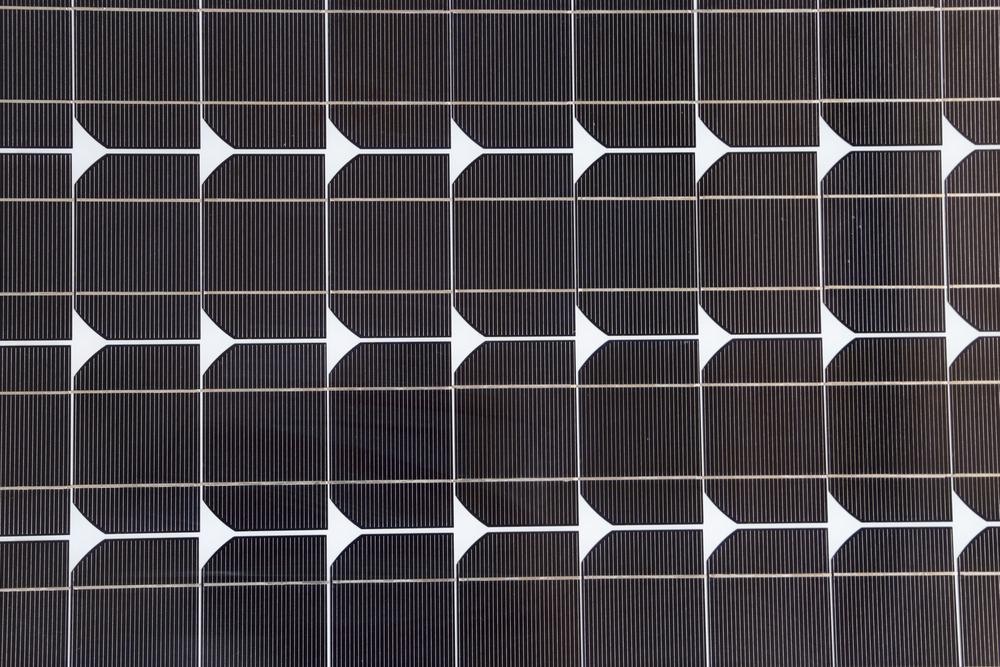

Study: Flexible Hybrid Perovskite Nanofiber for All-Inorganic Perovskite Solar Cells. Image Credit: NJH Photography/Shutterstock.com

Metal Halide Perovskites

Metallic halide perovskite substances have fascinating photovoltaic characteristics, a high coefficient of light absorption, and an inexpensive fabrication process, which offers a limitless area to utilize in the solar cell research field.

CsPbX3-based (X = I, Br, and Cl) fully synthetic perovskite materials, in particular, offer superior heat and light stability and be potential alternative options for optoelectronic systems such as solar cells.

The outstanding light and heat stability of fully synthetic metal halide perovskites may aid in the prevention of permanent chemical deterioration of perovskite materials in the presence of ambient conditions. As such, the life span of the perovskite solar cells (PSCs) is significantly extended.

Advantages of One-Dimensional Perovskite Nanostructures

With ultra-compact physical dimensions and appropriate aspect ratios, 1D perovskite nanoscale structures such as perovskite nanorods (PNRs) and perovskite nanowires (PNWs) can help decrease surface defects and grain boundaries, allowing for smooth and direct carrier transfer within singular crystalline paths and providing improved system performance.

Meanwhile, with suitable dimensions and a greater ratio of surface area to volume, they preserve amazing light-collecting potential and photophysical characteristics that are at least as good as their 3D perovskite nanostructured equivalents.

More importantly, the remarkable mechanical characteristics of 1D nanoscale structures suggest building very pliable PSCs.

Owing to these remarkable capabilities, 1D perovskite nanostructured materials have been developed and are extensively researched in the domains of sensors, solar power, and LEDs.

Benefits of the Electrospinning Technique

The electrospinning method, as a versatile and scalable assembling procedure for 1D nanoscale structures, has lately piqued the attention of researchers. It is regarded as a useful technique for producing thin-film, nanofibrous polymers with improved crystallinity, and nanorods or nanowires with tunable morphologies.

Moreover, electrospun nanofibers could be used to create composite nanofibers for various use-cases in photoconductive materials by acting as a useful and uncomplicated matrix for materials with varied functionalities such as 1D perovskite nanorods or nanowires, complexed polymers, and perovskite quantum dots (PQDs).

The electrospun nanofibrous membranes are highly porous, and the nanostructures link with each other in a network architecture, retaining outstanding elastic and flexible capabilities.

The benefits of electrospun nanofibers stem from the morphological containment aspect of their installation and the ability to manipulate the crystallization, direction, and optical characteristics of the perovskite nanoparticles contained in the nanofiber layers.

Due to electrospun polymeric nanofibers' presence, the installed PQDs integrated or scattered on the polymer nanofibers are isolated from one another, reducing agglomeration and preserving the intrinsic optical characteristics of these PQDs to a higher degree.

Based on these benefits, several scientists are engaged in examining electrospun nanofibers as the light absorbing component of PSCs, and even the morphological confinement effects, crystallizing, directional, and optical characteristics of perovskite nanocrystals.

Lately, electrospun polymer hybridized nanofibers with better optical absorption coefficients were utilized in the perovskite active layer of PSCs; nevertheless, the related power conversion efficiency (PCE) was severely poor. Moreover, the alignment and topology of perovskite nanocrystals in composite electrospun nanofibrous layers are strongly linked to the concentration of perovskite precursor solution.

Key Findings of the Study

This study presented an efficient method for manufacturing 1D pliable perovskite hybridized nanofibers as the light-capturing component of PSCs by electrospinning.

The proportion of PbBr2 in the precursor mixture influences the fluidity of the spinning mixture and the architectures of the perovskite nanocrystals on the nanofibrous layers. Furthermore, the inclusion of the polymeric scaffolding in the nanofibrous membranes may generate heterogenized nucleation, modify the crystallization, expansion, and alignment of the perovskite nanocrystals, and hence influence their photophysical characteristics.

Compared to the standard perovskite thin-film fabrication procedure, the electrospinning perovskite nanofibrous layers had outstanding mechanical characteristics and were not confined by the substrate. This would substantially simplify the pairing of PSCs with flexible materials, promoting the advancement of wearable electrical devices even further.

Continue reading: What Does an Alternative to Silicon-Based Solar Cells Look Like?

Reference

Ning, L., Gu, N., et al. (2022). Flexible Hybrid Perovskite Nanofiber for All-Inorganic Perovskite Solar Cells. Materials Research Bulletin. Available at: https://www.sciencedirect.com/science/article/pii/S0025540822000216?via%3Dihub

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.