A unique reusable and self-healing natural polymer hydrogel (Chitosan/polymethylacrylic acid-CMA) has been proposed by researchers from China in the latest article published in gels.

Study: Highly Flexibility, Powder Self-Healing, and Recyclable Natural Polymer Hydrogels. Image Credit: Gilmanshin/Shutterstock.com

Pros and Cons of Hydrogels

Hydrogels are nanoscale polymers that are water-swollen and have excellent hydrophilic three-dimensional (3D) networking due to mechanical or chemical crossing connections.

Hydrogels have distinct features due to their unique structure. They possess high inherent softness, natural hydrophilic nature, distinct swelling behavior as well as sensitivity to the physiological environment.

Hydrogel-based functional materials have stimulated the interest of researchers and have been widely employed in sorption polymers, controlled drug delivery, synthetic biology, and wearable elastic electrical devices in the past few decades.

Even though hydrogels have evident beneficial results, they are discarded due to permanent degradation (e.g., mechanical breaks, dryness or when part of the hydrogel is missing).

Due to the absence of meaningful recycling techniques, neglected materials contribute significantly to waste and environmental problems. As a result, a new reusable hydrogel with superior efficiency should be produced.

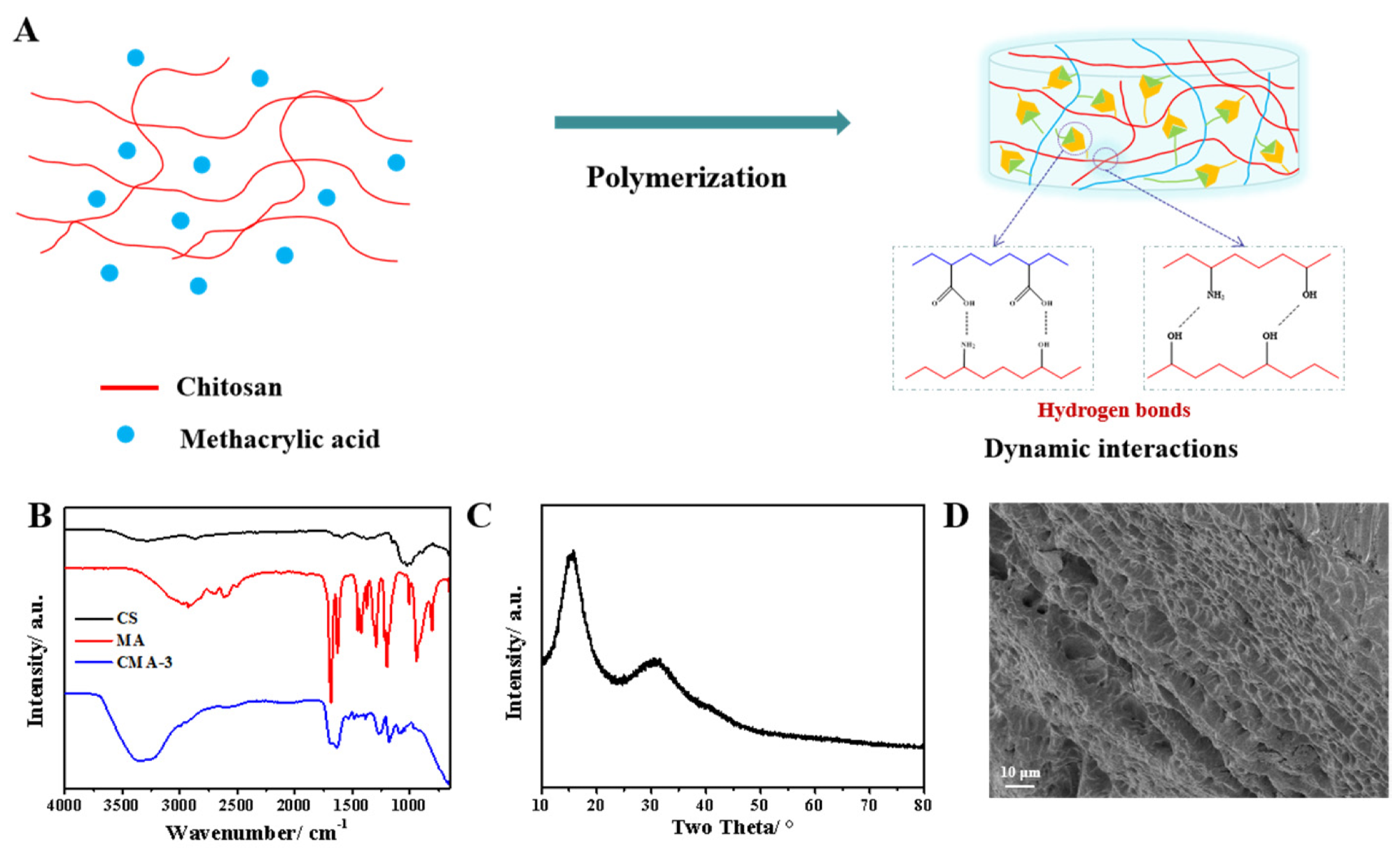

Figure 1. (A) Preparation of CMA hydrogels. (B) FTIR spectra of CS, MA and CMA-3 hydrogels. (C) XRD pattern of CMA-3 hydrogel. (D) SEM image of CMA-3 hydrogel.© H. Miao., et al. (2022)

Self-Healing Hydrogels

Diverse functional hydrogels have been developed in recent years to address the issues of reusability.

Self-healing hydrogel is thought to be an excellent choice for addressing mechanical stress. When touched by bidirectional and continuous contacts, the self-healing hydrogel may efficiently repair its structural system and restore its functionality.

Researchers created a hydrogel that could combine into one piece in 2 minutes and restore 87 percent of its mechanical strength after 40 minutes at 25 degrees Celsius.

Industrial Utilization of Hydrogels

Since the discovery of the first artificial hydrogels in 1954 by Wichterle and Lim, hydrogel techniques have been applied to agricultural production, drug carriers, medical products, synthetic biology, diagnostic testing, dressings, isolation of biological molecules or cells and barrier components to monitor and control genetic contractures, and biosensors.

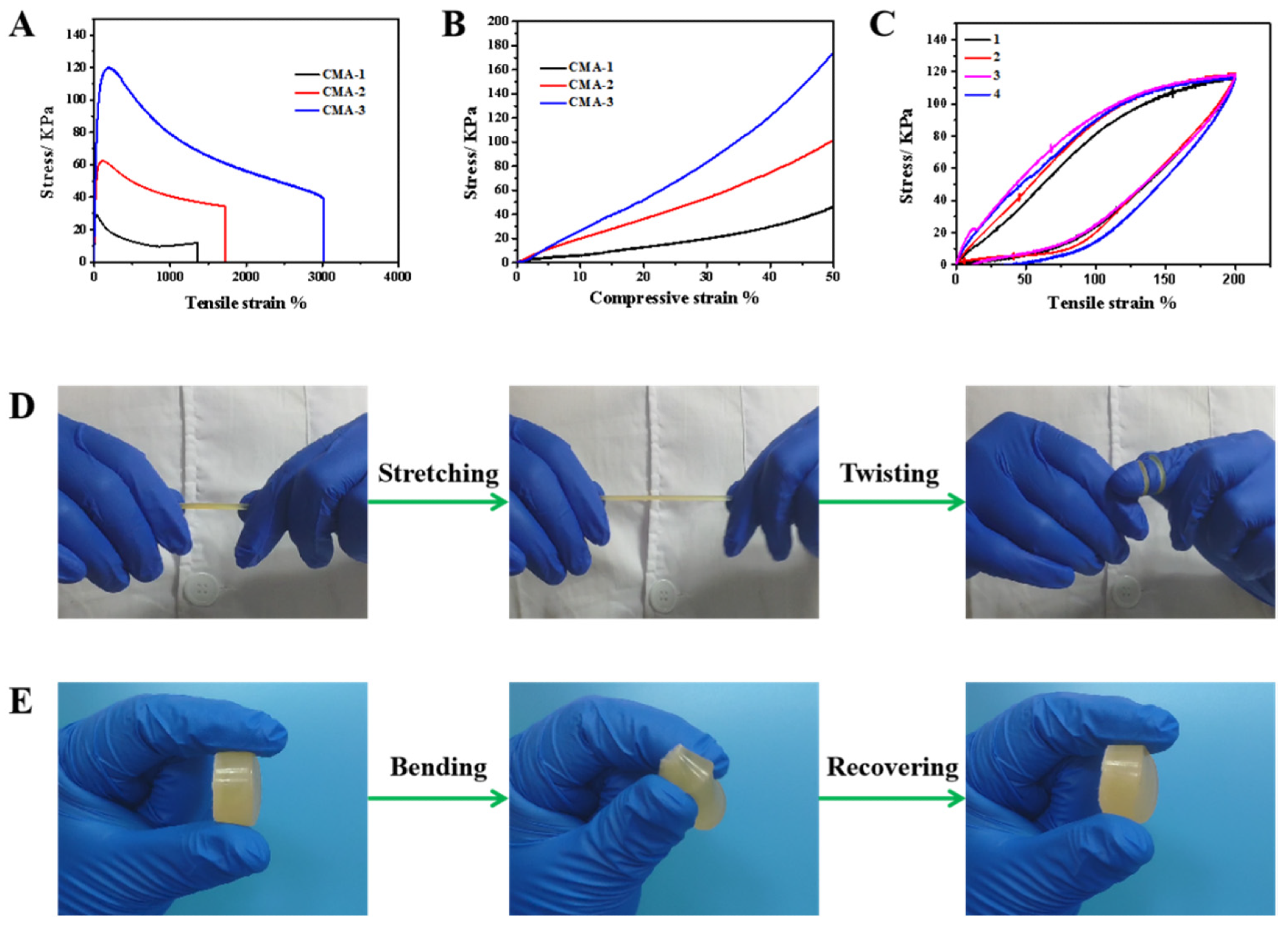

Figure 2. Mechanical properties of CMA hydrogels: (A) Tensile strain curve at 10 mm min−1. (B) Compressive strain curve at 5 mm min−1. (C) Stretching–releasing cycles. Photographs of CMA-3 hydrogel exhibiting excellent stretching and bending flexibility (D,E). © H. Miao., et al. (2022)

Various Technologies for Production of Hydrogels

While hydrogels are typically made using hydrophilic monomers, hydrophobic monomers are occasionally utilized to modify the characteristics for certain uses.

In general, hydrogels may be made from both synthetic and natural polymers. In its most basic form, a hydrogel is just a hydrophilic polymeric matrix that has been bridged in some way by producing a flexible framework.

As a result, any approach that can be used to manufacture a cross-linked polymer may also be utilized to build a hydrogel.

To make hydrogels, copolymerization/cross-linking free-radical polymerizations are often used.

Other technologies such as bulk polymerization, solution polymerization (often known as cross-linking), and suspension polymerization are used for their synthesis.

Research Findings

CMA hydrogels were manufactured using free radical polymerization by using bidirectional hydrogen bonding with 3D network architectures associated with the natural frame structure of Chitosan (CS) and functional monomer-methacrylic acid (MA).

Mechanical characteristics are an important performance metric to consider when evaluating hydrogel materials. The stress rose from 26 kPa to 125 kPa as the MA content grew from 1.0 g to 3.0 g, the tensile strain grew from 1357 percent to 3012 percent, and Young's modulus grew from 20.3 kPa to 42.9 kPa.

Under 50% compressing strain, the compression stress rose from 32 kPa to 176 kPa as the MA concentration grew from 1.0 g to 3.0 g.

It also displayed considerable flexibility without snapping. Even when subjected to human weight stress, the hydrogel was capable of maintaining consistency without splitting and rapidly return to its former state when the load was withdrawn.

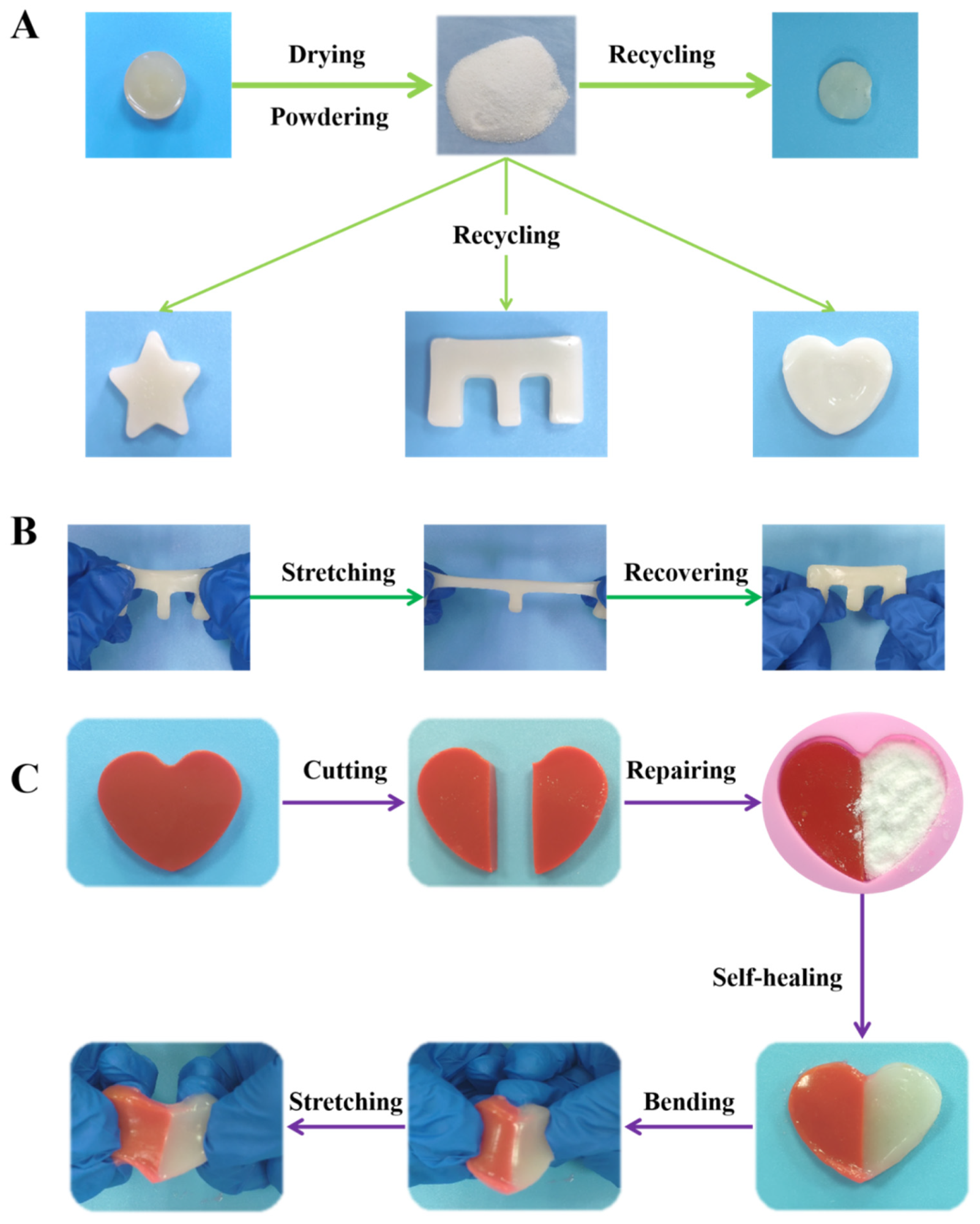

Two CMA-3 hydrogel discs were made and colored to directly illustrate this self-healing capability. The colorful hydrogel discs were split in half.

Following this, the red and orange halves were brought into contact at room temperature. After 1 minute, the two halves of hydrogels had effectively self-healed into a single one.

In short, the synthesized hydrogel demonstrated excellent mechanical, self-healing and failure recovery properties. Based on these benefits, the CMA hydrogel might be beneficial in a variety of applications.

Figure 3. (A) Photographs of powder self-healing abilities of CMA-3 hydrogel. (B) Photographs of CMA-3 hydrogel exhibiting excellent stretching flexibility. (C) Photographs of CMA-3 hydrogel repairing partially missing hydrogel. © H. Miao., et al. (2022)

Reference

H. Miao., et al. (2022) Highly Flexibility, Powder Self-Healing, and Recyclable Natural Polymer Hydrogels. Gels. 8(2). 89. Available at: https://www.mdpi.com/2310-2861/8/2/89

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.