According to a recent study published in the journal Nano Letters, van der Waals forces facilitate controlled crystal building of graphene and single-layer hexagonal boron nitride to produce wafer-scale sheets of clean boundaries with near-unity efficiency.

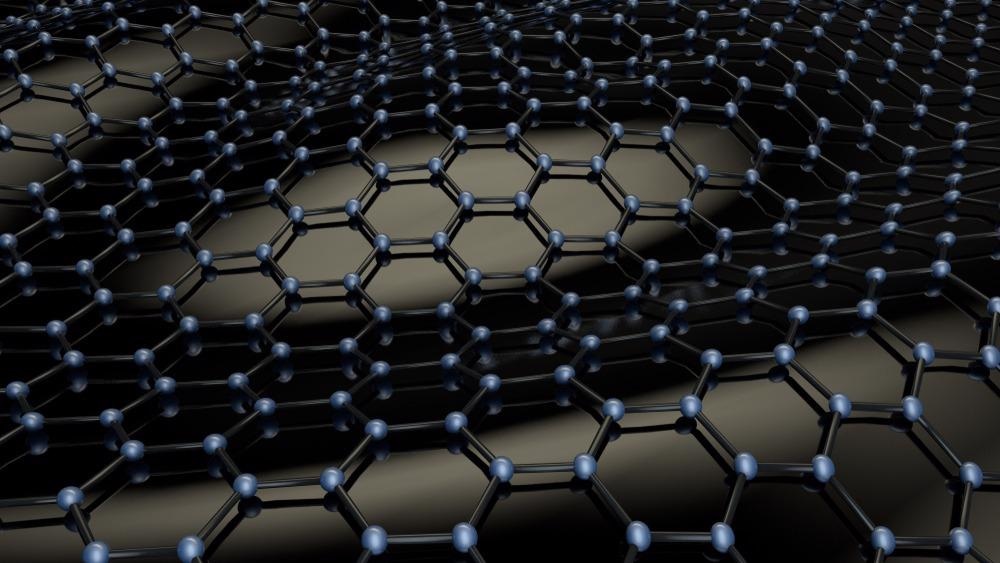

Study: Wafer-Scale Programmed Assembly of One-Atom-Thick Crystals. Image Credit: 3DStach/Shutterstock.com

Based on the modification of their depths and molecular architectures, polycrystalline films have a variety of physical characteristics.

The layer-by-layer construction of nanoscale crystals provides a significant method of flexibly designing films at the atomic scale, which is impossible to do with current growing processes.

However, molecularly pure material synthesis with great flexibility and repeatability continues to be a challenge.

Advantages of Assembly of 2D Materials

Following the separation of graphene, the assembling of diverse two-dimensional (2D) compounds into artificial structures has been extensively investigated for the invention of novel features and the production of improved nanotechnology.

The construction of 2D materials allows a range of van der Waals configurations through architectural degrees of freedom that are hard to construct with traditional base material or surface modification methods that rely on self-assembly mechanisms and have two distinct benefits.

For starters, the isolation of the development and assembling phases allows for a variety of combinations with unsuitable growing conditions.

Second, since there are no chemical interactions between neighboring layers, the crystallographic alignment of different layers can be controlled to change the molecular geometries of the whole structure.

Several layered architectures have been created to support controlled interactions with different constituent atoms, notably electrons, protons, phonons, and polaritons, even with modest variants of 2D materials.

The essential building components, graphene, and hBN have superior electrical, photonic, and physical capabilities.

Arrangement of 2D materials, aided by van der Waals forces, results in, regulated surfaces that control the attributes of final layers.

Limitations of Current Assembly Methods

Due to the absence of dependable manufacture of homogenous assembly units, current mechanical techniques for assembling graphene and hBN have limited productivity.

They are made by either peeling layers from crystalline structures or growing sheets using chemical vapor deposition (CVD).

The thickness of crystalline structure limits the size of exfoliated layers, which have a regionally nonhomogeneous thickness and tiny diameters, often on the order of tens of micrometers.

Wafer-scale films with oriented crystalline phases are produced by CVD nucleation and growth; however, the traditional approach for assembling the films entails a wet process, which introduces interstitial impurities.

The construction of large-scale transition metal dichalcogenides has progressed rapidly in recent years; yet, molecularly pure synthesis of graphene and hBN crystals remained unclear and continues to be a vital technology to be explored.

Programmed Crystal Assembly of Graphene and ML hBN

In this study, the researchers provide a method for fabricating high-quality, spatially homogeneous multilayered sheets using programmed crystal assemblies (PCA) of graphene and single-layer hexagonal boron nitride (ML hBN).

The primary possibilities of this assembly approach are shown in two cases.

The first is a graphene/hBN lateral superlattice, which is made by layering graphene and ML hBN alternatively to a maximum layer count of NL =5.

The second instance is chromatic twisted graphite (CTG), which is made by NL bending sheets about the mounting plane while keeping the intermediate revolution unchanged.

The PCA technique also allows for the flexible and efficient incorporation of a variety of 2D materials, providing a comprehensive framework for the construction of innovative van der Waals architectures.

As an example, homogeneous graphene/MoS2 superlattices were formed by integrating as-grown MoS2 sheets with graphene at near unity efficiency.

Research Findings and Prospects

According to the results, the PCA approach can program materials' inherent features by controlling not only their scale but also their molecular form, ushering in a new age of "nano-topo-technology."

A designer technique may create a variety of aggregates with single-atom accuracy on a wafer-scale to examine reactions with basic components, allowing for the identification of diverse physical characteristics.

In contrast to natural crystallites, van der Waals crystals with regulated surfaces may provide strong infrared light sensitivity, extremely thin thermal separation, improved conductance, and rapid ion dispersion at van der Waals surfaces.

This dependable and scalable technology may be used to investigate increasingly complicated structures and speed up the creation of sophisticated van der Waals crystal-based electronics.

Reference

Yang, S.-J. et al. (2022). Wafer-Scale Programmed Assembly of One-Atom-Thick Crystals. Nano Letters. Available at: https://pubs.acs.org/doi/10.1021/acs.nanolett.1c04139

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.