In a study published in the journal Results in Materials, graphene nanosheets (GNs) produced from waste plastics were synthesized for cost-efficient thermoelectric (TE) devices.

Study: Graphene nanosheets derived from waste plastic for cost-effective thermoelectric applications. Image Credit: MOHAMED ABDULRAHEEM/Shutterstock.com

An Introduction to Thermoelectric Devices

As energy demands rise, there is an urgent need to improve energy production to meet the demands for various applications.

The rise in global warming caused by increased energy usage is a significant source of worry. Therefore, there is a pressing need to identify long-term strategies to reduce net ecological effects by replacing traditional power supplies with sustainable sources of energy.

Currently, a large amount of poor-quality thermal energy is unavoidably created and, sadly, wasted in everyday living and commercial operations.

Thermoelectric (TE) substances may generate power from waste heat. Even at relatively small temperature gradients compared to the ambient temperature, TE systems are capable of directly converting heat into electricity by utilizing the movement of solid inner carriers.

The effectiveness of TE devices is determined by the kind of TE substances utilized in the operation.

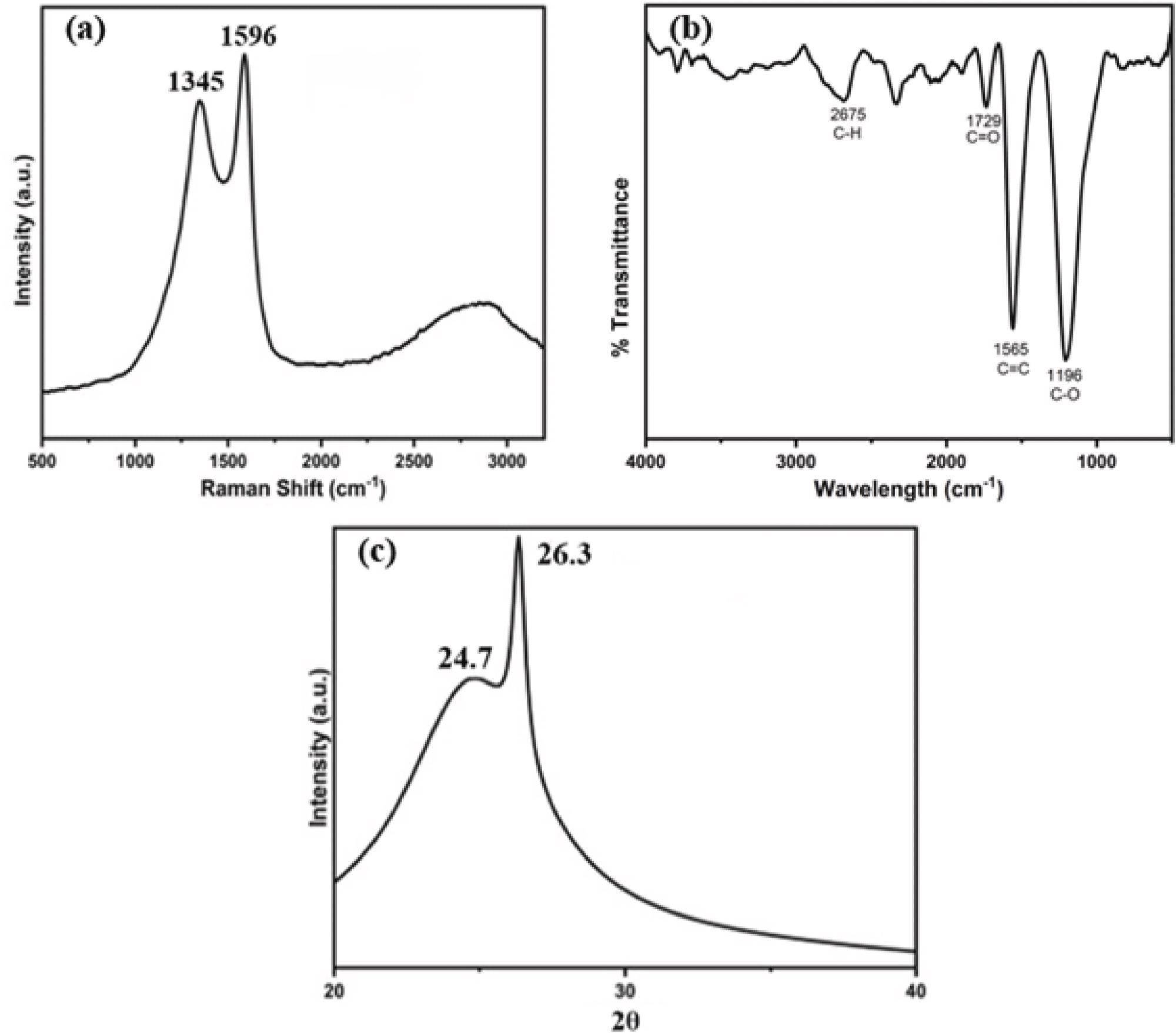

Figure 1. (a) Raman Spectra of reduced graphene nanosheets from waste plastics, (b) FT-IR spectra of graphene nanosheets from waste plastics, (c) XRD spectrum of graphene nanosheets from waste plastics. © Garg, K. K., Pandey, S., Kumar, A., Rana, A., Sahoo, N. G., & Singh, R. K. (2022)

Advantages of Using Graphene

Scientists have shown the applicability of carbonaceous nanomaterials for the implementation of TE devices owing to their simplicity of fabrication and exceptional features.

Graphene is recognized as one of the worthy options because of its superior mechanical, electrical, and thermal capabilities. Its distinctive 2D honeycomb framework has carbon atoms in the sp2 state, providing it with a planar shape.

At normal temperatures, graphene also exhibits exceedingly large charge carrier movement and a variety of quantum phenomena. This indicates its possible use in next-generation field-effect transistors.

Furthermore, the science world has a hurdle in the bulk production of GNs to investigate real-time uses of graphene for efficient energy storage and conversion devices.

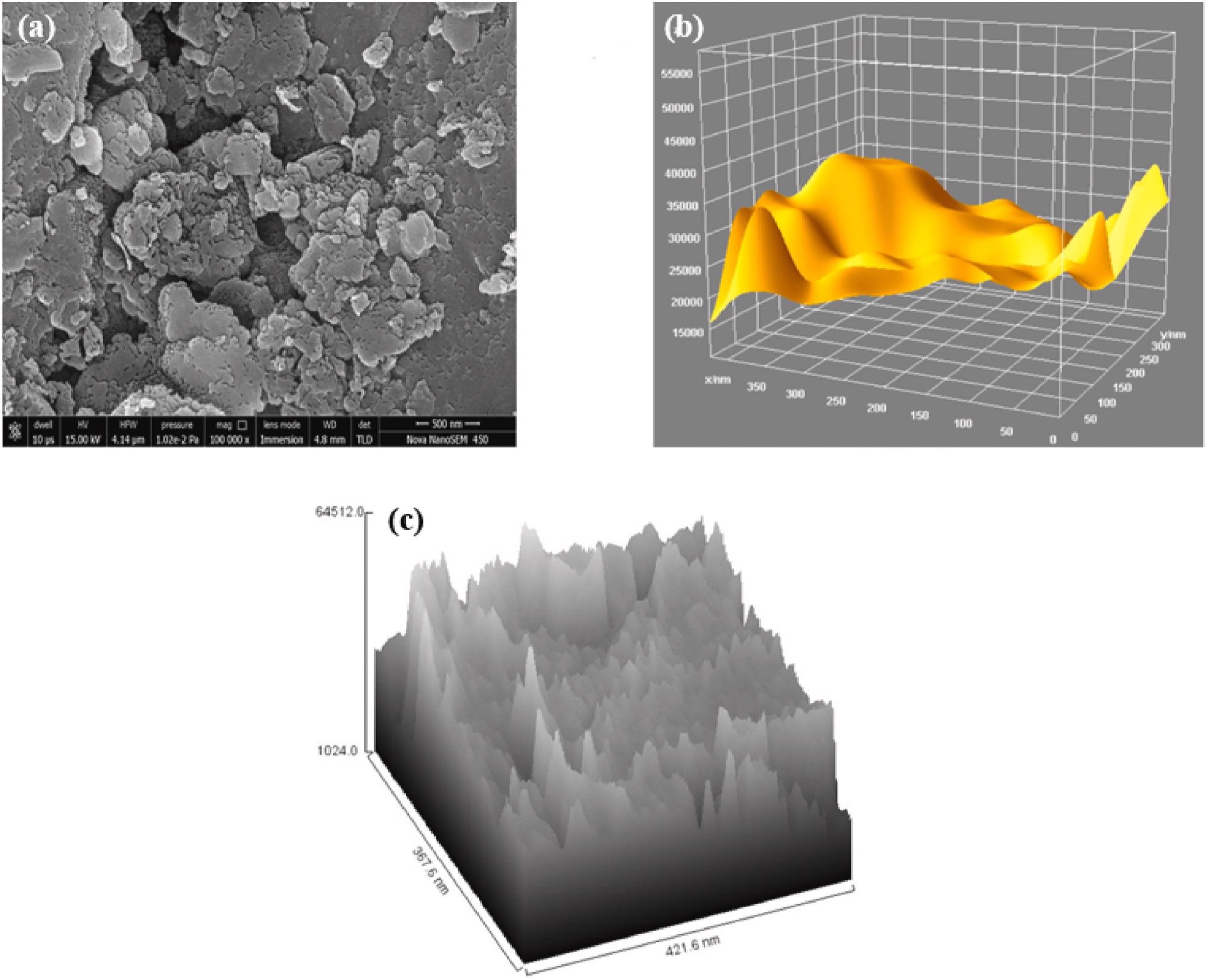

Figure 2. (a) FESEM image of waste plastic derived reduced GNs, (b) 3D surface plot from the FESEM image of reduced GNs from waste plastics, (c) surface plot from the FESEM image of reduced GNs from waste plastics. © Garg, K. K., Pandey, S., Kumar, A., Rana, A., Sahoo, N. G., & Singh, R. K. (2022)

Addressing the Problem of Synthesizing Graphene

Many experts have revealed a promising method for obtaining good-quality graphene using solid garbage materials in this respect.

Due to its non-biodegradable nature, plastic garbage has greatly contributed to an urgent scenario amongst solid waste products.

The current volume of waste plastic has created a difficult problem that has already triggered a number of environmental difficulties. Fortunately, the substantial carbon composition of plastics provides us with a new avenue for improved plastic waste management via the creation of value-added goods.

While there are several ways known for the fabrication of graphene, including chemical procedures, chemical vapor deposition (CVD) and electrolytic exfoliating methods, the production of graphene utilizing these procedures is very time-consuming and expensive.

As a result, using graphene created by these processes in cost-efficient commercial operations becomes extremely challenging.

This study illustrated a mass manufacturing method that can deliver high-quality GNs in a very cost-efficient way; thus, the current form of graphene may be employed for a myriad of practical applications such as dye-sensitized solar cells, perovskite solar cells, supercapacitors, and cementing applications.

These real-world implementations of plastic waste-derived GNs demonstrate the prospects of this study, which not only reduces the concentration of solid plastic waste in the environment but also provides a productive route to convert waste to energy.

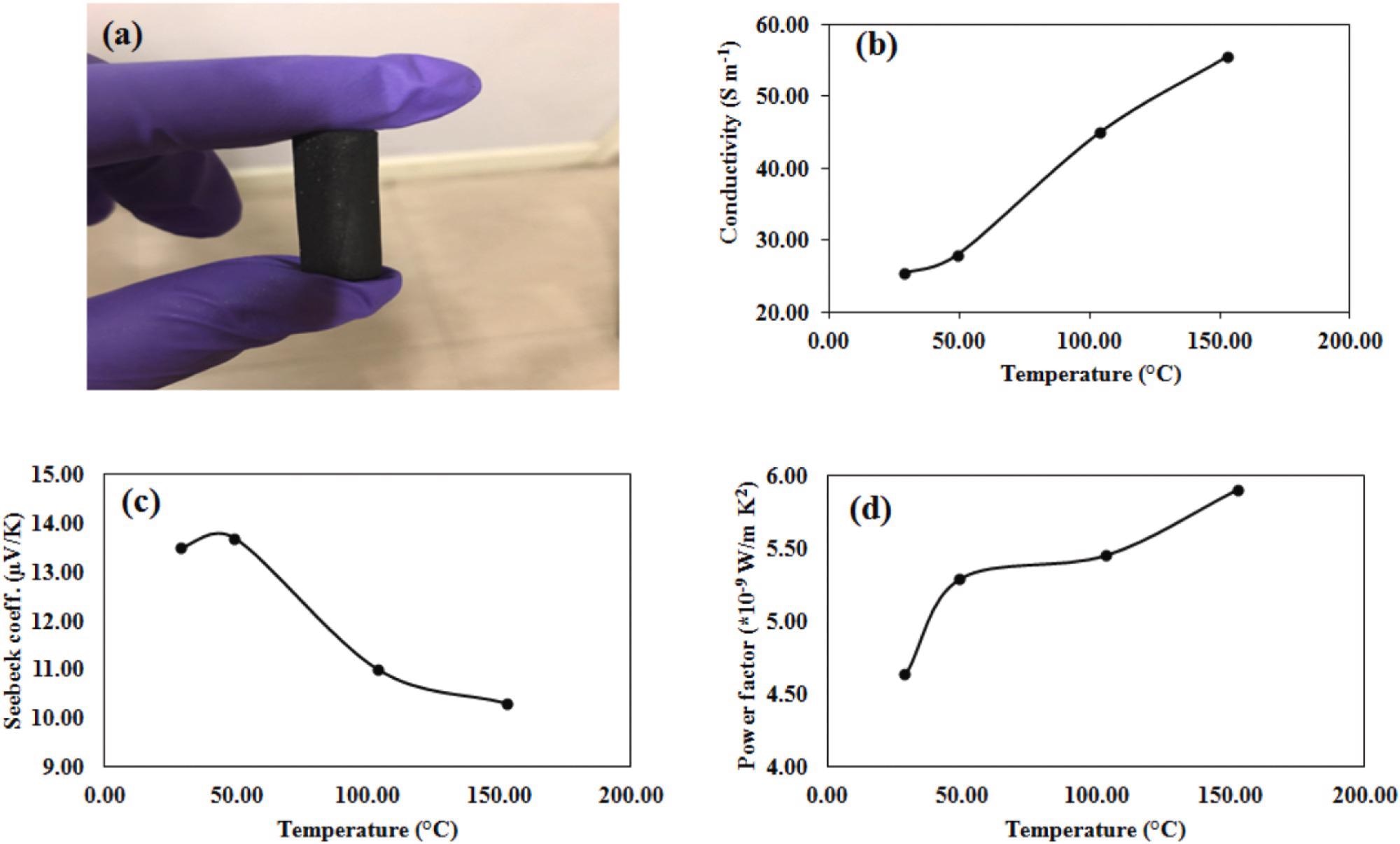

Figure 3. (a) Vertical image of the GNs based rectangular bar (12 mm × 5 mm × 5 mm) for TEs applications, (b) Conductivity graph for the GNs, (c) Seebeck coefficient graph for the GNs, (d) Power factor analysis for the GNs. © Garg, K. K., Pandey, S., Kumar, A., Rana, A., Sahoo, N. G., & Singh, R. K. (2022)

Important Findings of the Study

In this study, the team successfully synthesized inexpensive GNs from plastic wastes utilizing inexpensive Al2O3 through the previously disclosed two-step pyrolytic procedure.

With the existence of the edge flaws, the GNs produced were determined to be 3–4 nm thick. The existence of edge flaws inside the GNs resulted in semiconductive characteristics within the synthesized GNs.

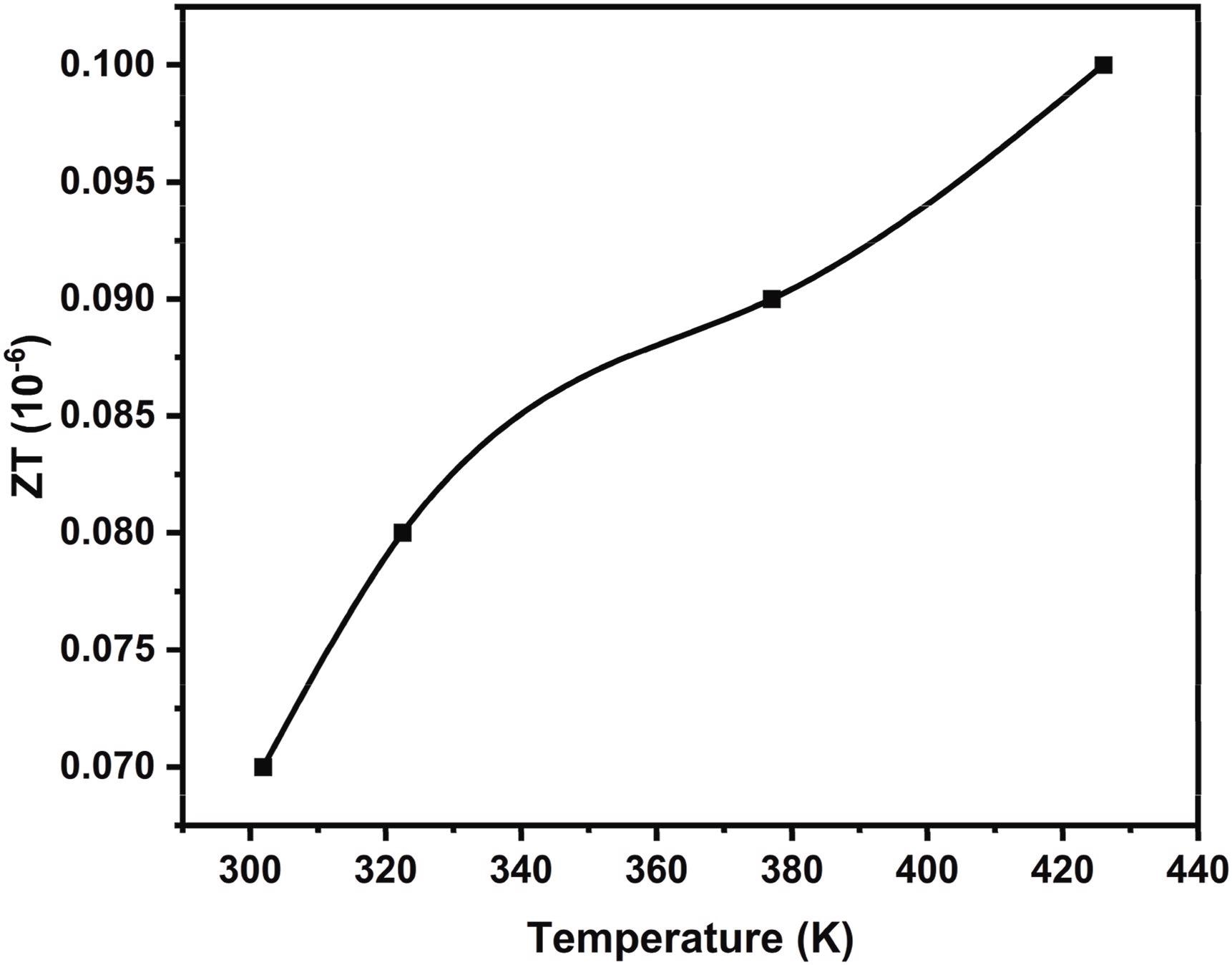

The thermoelectric properties of the GNs were also examined to assess the practicality of the method.

Simultaneous increases in electric conductance and the Seebeck coefficient were discovered, indicating that the GNs had strong TE properties. As a result, the synthesized GNs may be used as a contender for TE materials in a range of TE devices.

Figure 4. Thermoelectric figure of merit (ZT) of waste plastic derived GNs. © Garg, K. K., Pandey, S., Kumar, A., Rana, A., Sahoo, N. G., & Singh, R. K. (2022)

Reference

Garg, K. K., Pandey, S., Kumar, A., Rana, A., Sahoo, N. G., & Singh, R. K. (2022). Graphene nanosheets derived from waste plastic for cost-effective thermoelectric applications. Results in Materials, 13. Available at: https://www.sciencedirect.com/science/article/pii/S2590048X22000085?via%3Dihub

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.