Graphene and boron nitride show great potential as fillers in polymer matrices and as photocatalysts because of their desirable chemical and physical properties. However, their widespread usage is limited because economic mass production remains a challenge.

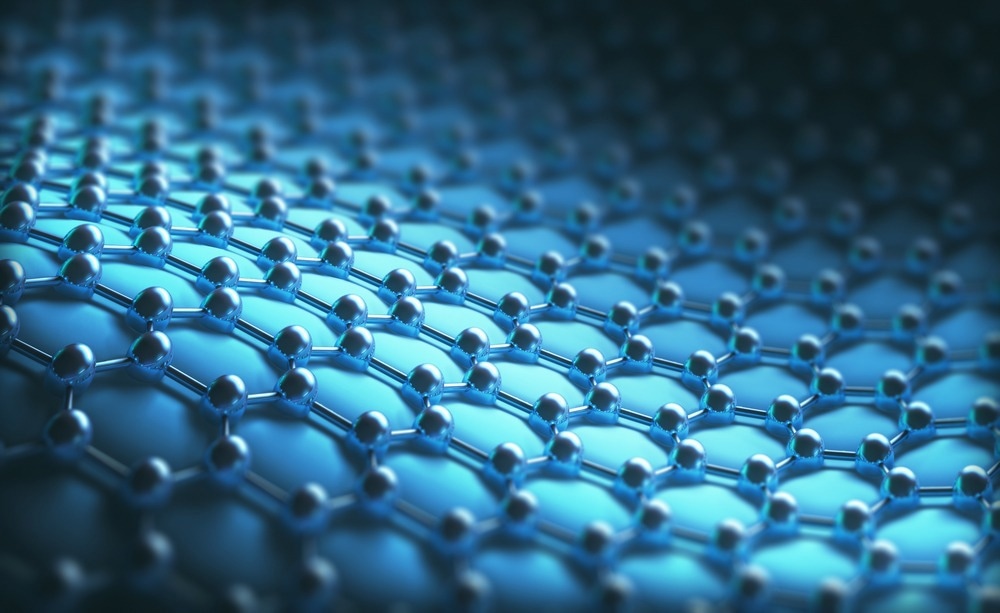

Study: One-Step Green Production of Biocompatible Functionalized Few-Layer Graphene/Boron Nitride Nanosheet Hybrids Using Tannic Acid-Based Liquid-Phase Exfoliation. Image Credit: ktsdesign/Shutterstock.com

With this in mind, a new method of producing biocompatible nanohybrids made of boron nitride and tannic acid was published in the journal ACS Sustainable Chemistry & Engineering.

Importance of Few-Layer Graphene

The highly desirable physical qualities of graphene, including its superior elastic modulus, high thermal conductivity and high surface area, make it a very suitable candidate for use in catalytic, medical, electrical, and biomedical applications. Potential areas of use range from nanohybrids and supercapacitors to wastewater management and treatment.

A hexagonal honeycomb-like lattice of very thin sheets of carbon atoms makes up a graphene few-layer film. Three processes: microwave treatment, nanodiamond conversion, and graphite arc discharge, are used to create few-layer graphene.

2D functionalized few-layer graphene (FFG) sheets with a C/O ratio of around two are formed when sp3 hybridized carbon atoms are joined in a 2D hexagonal sheet with an array of oxygen functionalities on both sides.

Boron Nitride vs. Graphene – A Comparison

Hexagon-shaped boron nitride has intrigued material scientists due to its peculiar chemical properties. As boron nitride atoms are alternatively connected and arranged in a configuration where two atoms in adjoining layers are occluded on top of one another owing to polarity mismatch, it differs from graphite.

However, interest in boron nitride has increased because of its inert chemical nature, biocompatibility and high thermal properties.

Boron Nitride Nanosheets (BNNs)

Nanohybrids composed of boron nitride can significantly improve the mechanical properties of their host matrix. BNNs show elevated performance levels in terms of fracture strength, thermal conductivity, and thermal stability.

BNNs, therefore, hold the potential to be engineered with other nanohybrids, as a filler in polymer matrices to improve their performance.

Challenges in the Production of BNNs and Graphene

Further use of these high-performance materials is restricted by their environmental sustainability as well as scalable production.

Green medicinal biomolecule tannic acid-based liquid-phase exfoliation was used in this work to try and develop a green technique for manufacturing FFG/BNN nanohybrids.

Tannic Acid-based Liquid Exfoliation Approach

Tannic acid-assisted techniques for synthesizing nanomaterials can result in highly hydroxyl- and carboxyl-functionalized materials, which are crucial for real-world applications.

Tannic acid has not been used for direct exfoliation in the hybridization of 2D nanohybrids before now. In this research, it was employed as a green stabilizing and exfoliating agent.

The most suitable surface modifier for improved chemical and physical properties of nanoparticles and 2D nanohybrids is tannic acid, which is one of the most prevalent green compounds with high levels of pyrogallol-catechol groups. The FFG/BNN that was constructed displayed long-term dispersion stability.

The authors argued that this technique, being easily employable and having a high yield, can not only show applications of FFG/BNNs as standalone compounds but also can be used for improving the mechanical properties of nanohybrids by acting as a filler in the polymer matrices.

Future Prospects and Implications of the Research

This research provides an important methodology for creating FFG/BNNs at a large scale and managed to achieve the highest yield of 57.3%. However, the possibility of tweaking the parameters such as raw material and nanohybrid ratio can be explored and exploited to achieve even higher yield and would provide more insight into the dynamics of two-dimensional materials.

If verified to be massively reproducible, this method could be utilized by research groups and industries to manufacture improved FFG/BNN hybrids while maintaining an eco-friendly approach.

Reference

Deshmukh, A. R., Chaturvedi, P. K., Lee, S.-Y., Park, W.-Y., & Kim, B. S. (2022). One-Step Green Production of Biocompatible Functionalized Few-Layer Graphene/Boron Nitride Nanosheet Hybrids Using Tannic Acid-Based Liquid-Phase Exfoliation. ACS Sustainable Chemistry & Energy. Available at: https://doi.org/10.1021/acssuschemeng.2c02484

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.