Variants of commercial grade alloys with nanocrystalline structure show great promise for enhanced mechanical properties, ultimately helping reduce waste and retain sustainable supply chains.

Study: Mechanical properties of friction induced nanocrystalline pearlitic steel. Image Credit: lbrumf2/Shutterstock.com

In a paper published in the journal Scientific Reports, the fabrication and analysis of frictional nanostructured steel are carried out using the machining method. Rapid cooling of the developed chip was used to stabilize the nanocrystalline assembly.

Fabrication Approaches for Nanostructured Metals

Nanostructured metals have been at the forefront of a myriad of technological developments recently. The fabrication of nanocrystalline structured metals is usually carried out using top-down or bottom-up approaches.

In the top-down method, rough structures are refined mainly using the process of severe plastic deformation (SPD). In the bottom-up approach, materials are assembled by atomic or molecular aggregation. Examples include vapor deposition or quick solidification processes.

SPD procedures restructure the entire specimen, resulting in a unique bulk material with distinct characteristics governed by the nanocrystalline arrangement. Other approaches, which have received much less attention and development, focus only on surface modifications.

Advantages of Nanostructured Metals

The mechanical characteristics of nanocrystalline metallic structures are considerably different from those of their coarse-grained analogs.

The toughness and tensile strength of nanocrystalline metallic structures are particularly high as a result of the reduced movement of linear dislocations contained within grain boundaries (GBs). These properties can offer certain technical advantages.

Important Findings of Previous Studies

Surface coatings having a micrometer grain size of less than a micrometer have been documented. The settings needed for developing these surface coatings are expected to be different from those needed for nanocrystalline structuring of the whole bulk material.

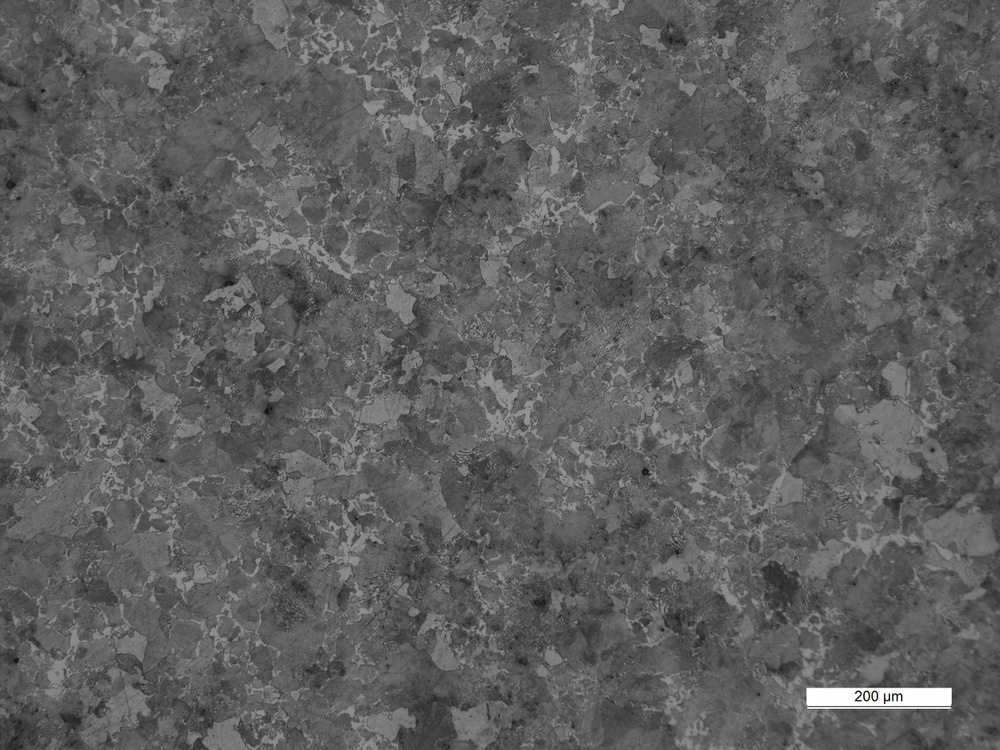

Analyses of the chip friction surface revealed significant refinement as well as considerable changes in the arrangement of the alloy's constituents.

In the top layer, the size of grains measured in the friction surface of AISI 1045 carbon steel did not exceed 100 nm.

A dynamic recrystallization approach resulted in the refinement of crystal sizes, along with a significant rearrangement of the alloying components from the initial pearlitic structure and a decrease in residual stress.

Friction-Induced Nanomaterials

Bulk nanocrystalline metallic structures are often defined by a rise in hardness and a detrimental loss in thermal stability, which is typical for top-down and bottom-up manufacturing approaches.

Meanwhile, there is a growing focus on investigating mechanical characteristics of the intermediate and finalized phases of thin sheets of friction-induced nanomaterials (FIN).

Pillar test investigations have revealed that FINs possess distinct collapsing patterns under ultimate compressive stresses and high material strength. This indicates that their deformation mechanisms are completely unique.

FINs deviate significantly from existing nanomaterials concerning thermal stability. They exhibit remarkable thermal stabilities akin to supramicron structured alloys. FINs were created at cryogenic settings via surface sliding, which resulted in rapid localized self-heating because of the high strain rates and subsequent rapid cooling.

The steel undergoes quick machining, in which massive strain rates are used to heat up the material to 0.6 times the melting temperature and then cool down in milliseconds. Afterward, similar grain sizes may be easily achieved in the chip.

This technique may therefore serve as a benchmark for testing the characteristics of future nanocrystalline alloy structures.

Significant Findings of the Research

In this study, the team examined the FIN produced from AISI 1045 carbon steel via a rapid cutting procedure. The specimens were subjected to structural, morphological, chemical, and mechanical analysis.

The assessment of bulk-equivalent tensile strength at various grain sizes, even sub-100 nm crystalline materials, was made possible by a series of pillar compressions and the crystal size gradient inside the chip surface.

Results of the Research

The FIN sheet was formed during machining from AISI 1045 carbon steel, which was distinguished by a gradient of internal stresses and crystal size.

The uppermost 5 µm of the FIN sheet was subjected to rotational dynamic recrystallization and rapid cooling, which maintained the crystal size at 100 nm. In the ferrite lattice, carbon was distributed evenly.

The recrystallized sheet showed a strength of 2000 MPa, which was about thrice that of pure AISI1045. The modulus of elasticity of the nanocrystalline layer was lowered by 12% when compared to pure AISI1045.

Reference

Medina-Clavijo, B., Rafael-Velayarce, J. et al. (2022). Mechanical properties of friction induced nanocrystalline pearlitic steel. Scientific Reports, 12. Available at: https://www.nature.com/articles/s41598-022-16848-2

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.