Researchers at the KTH Royal Institute of Technology have created a miniature robotic muscle substance that breaks through brick walls. With electronic impulses of less than one volt, the material—a specially developed hydrogel—can shape-shift, expand, and compress on demand.

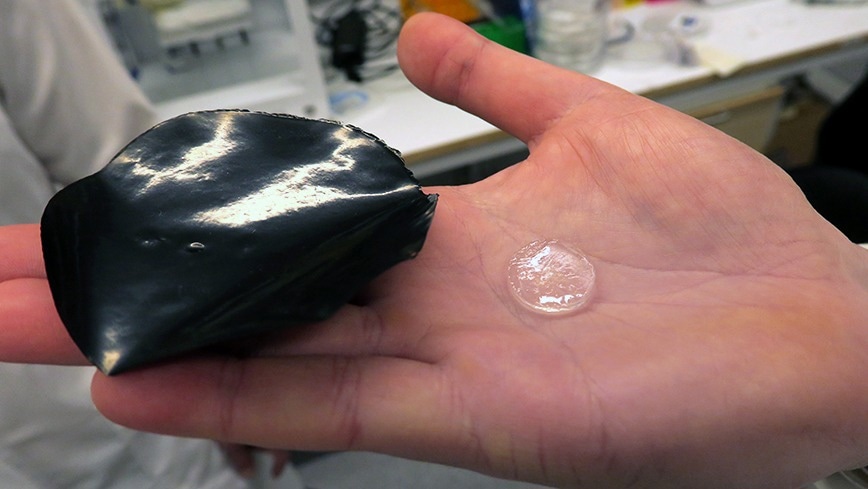

The hydrogel muscle (left) and a piece of hydrogel before being combined with carbon nanotubes. Image Credit: David Callahan

The hydrogel muscle (left) and a piece of hydrogel before being combined with carbon nanotubes. Image Credit: David Callahan

The material is constructed of cellulose nanofibers (CNFs) generated from wood, and robotics is just one potential application it can be used for. Potential applications of the technique include biochemical synthesis and medicine.

The KTH Royal Institute of Technology researchers published their findings in Advanced Materials.

According to Tobias Benselfelt, a researcher at the KTH Royal Institute of Technology’s Division of Fibre Technology, these hydrogels swell as a result of water movement driven by electrochemical pulses, in contrast to robotic muscles that expand in response to pressured air or liquid.

The main ingredients of the material are water, wood pulp-derived cellulose nanofibers, and carbon nanotubes, which act as a conductor. Despite being a hydrogel, the material takes on the appearance of plastic strips when mixed with carbon nanofibers.

Inspired by Plants

The strength of the material stems from the nanofibers’ arrangement in the same direction as wood grain.

Nanofiber hydrogels swell uniaxially—on a single axis—generating high pressure. A single 15×15cm piece can lift a 2-tonne car.

Tobias Benselfelt, Researcher, Division of Fibre Technology, KTH Royal Institute of Technology

By incorporating conductive carbon nanotubes into the hydrogel, the material’s swelling could be electronically regulated, leading to the creation of what the researchers refer to as electrochemical osmotic hydrogel actuators.

The study’s co-author, Max Hamedi of KTH, contends that the growth patterns of plants served as inspiration.

Think about how strong plants are. Trees can grow up through the pavement by the same forces that we are applying—we are just controlling that force electronically.

Max Hamedi, Associate Professor, Division of Fibre Technology, KTH Royal Institute of Technology

Potential Uses

According to Benselfelt, an intriguing feature of the research is the ability to electronically regulate the porosity of the material. These hydrogels have the potential to enhance porosity by 400 percent, which makes them the perfect material for electrotunable membranes that are intended to segregate or distribute medications or molecules in real-time.

This perfectly controlled expansion also allows the material to apply enough force to break a small brick, as demonstrated by the researchers in connection with their study. However, for the time being, the researchers believe they will be limited to small devices such as valves or switches in microfluidics.

Hamedi added, “Currently, they come in thin sheets, which limits their use as artificial muscles for larger robots.”

Looking further into the future, underwater robots could be a feasible robotics application. According to Benselfelt, they can be employed at vast depths since hydrogels cannot be squeezed by water pressure.

Benselfelt noted, “Generally, it is a step towards soft machines that are lifelike. However, this vision is very far in the future.”

Another advantage of the technology is that it is quite cheap to produce. The team is still working to improve the material, 3D-print electrical muscles, and figure out how to scale it for commercial application.

The study was conducted at KTH Royal Institute of Technology and the Digital Cellulose Center, with researchers from the Max Planck Institute of Intelligent Systems, Linköping University, and Technische Universität Braunschweig.

Journal Reference:

Benselfelt, T., et al. (2023) Electrochemically Controlled Hydrogels with Electrotunable Permeability and Uniaxial Actuation. Advanced Materials. doi:10.1002/adma.202303255