According to a study published on June 25th, 2024, in Carbohydrate Polymer Technologies and Applications, Japanese researchers from Yokohama National University have developed holocellulose nanofibers (HCNFs) and discovered a preservative-free method for long-term storage. This advancement not only preserves the HCNFs but also offers significant benefits for transport and handling, greatly enhancing their potential applications in the food and cosmetic industries.

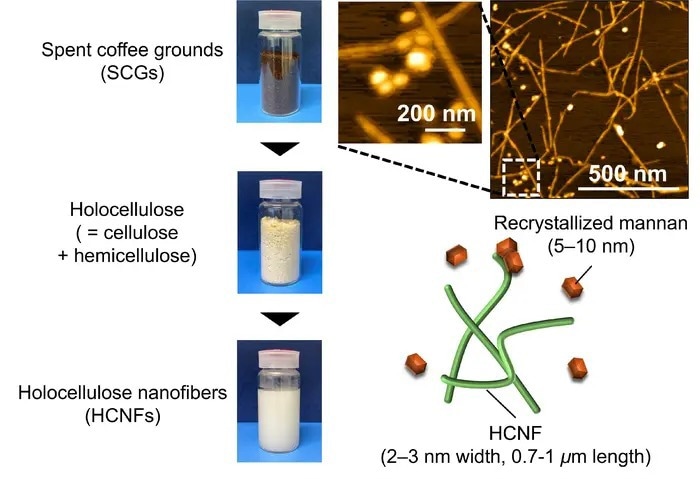

Spent coffee grounds are purified to yield holocellulose, which is then reduced to HCNFs using mechanical nanofibrillation. The HCNFs are 2-3 nm and 0.7-1 mm in length. An AFM (Atomic Force Microscopy) image of the HCNF shows recrystallization of mannan. Image Credit: Noriko Kanai, Graduate School of Information Sciences, Yokohama National University.

Each year, over 6 million tons of spent coffee grounds are generated globally from the coffee we consume. While some of these grounds are repurposed as biofuel, the majority end up in landfills.

Over the past decade, research has increasingly focused on finding sustainable ways to reuse these grounds, particularly by extracting polysaccharides from the cellulose and hemicellulose found in the cell walls of ground coffee beans. These polysaccharides have wide-ranging applications in composites, biopolymers, food packaging, construction materials, and cellulose nanofibers (CNFs). CNFs, which are cellulose particles reduced to a nanoparticle size of 3 to 5 nm, are especially valuable in the food, cosmetic, and coating industries.

In 2020, Japanese researchers from Yokohama National University pioneered a method to isolate CNFs from spent coffee grounds using TEMPO-mediated oxidation. However, this method left up to 40 % of the hemicellulose in the coffee grounds unused. To address this, the researchers shifted their focus to holocellulose—a combination of hemicellulose and cellulose—to extract holocellulose nanofibers (HCNFs).

Chemically unmodified and uniform quality HCNFs from agricultural/food waste are highly desirable for food additives such as emulsifiers. We hypothesized that the high hemicellulose contents in the holocellulose from spent coffee grounds and their unique structure could achieve completed nanofibrillation down to 3–5 nm wide and 1–3 μm long by mechanical disintegration.

Izuru Kawamura, Professor, Faculty of Engineering, Yokohama National University

Not only did the researchers successfully form HCNFs, but they also discovered a preservative-free method for long-term storage, which offers additional benefits for transport and handling. This breakthrough significantly enhances the utility of HCNFs in the food and cosmetic industries.

To create HCNFs from spent coffee grounds, the researchers first removed lignin and lipids, then reduced the remaining holocellulose fibrils to the nanoscale through a process called nanofibrillation, which involves disintegrating fibril bundles into nanofibrils. They employed a jet mill with ultrahigh water pressure to mechanically nanofibrillate the holocellulose, forming the HCNFs.

A key component in this process is mannan, the least degraded hemicellulose left in spent coffee grounds after roasting. Mannan has been shown to form a network between cellulose fibrils, a bond so strong that even chemical treatments may not fully break it. In some cases, mannan may even recrystallize.

The presence of mannan proved crucial in the reconstitution of HCNFs after freeze-drying. Typically, the physical properties of nanocellulose are altered during dehydration, making it difficult to redisperse in water. However, when freeze-dried HCNFs were placed in room temperature water, they easily redispersed to the nanoscale with just a simple shake.

The spent coffee grounds-derived HCNFs were completely nanofibrillated to 2–3 nm wide and 0.7–1 μm long, which was finer in width and shorter in length than general CNFs or HCNFs obtained by mechanical nanofibrillation, and desirable morphologies for food additives.

Noriko Kanai, Assistant Professor, Faculty of Environment and Information Sciences, Yokohama National University

Not only did they produce finer and shorter HCNFs, but the discovery of the HCNF's specific behavior in the freeze-dried condition offers several advantages.

Kanai added, “The advantages of the once-freeze-dried HCNFs from spent coffee grounds are 1) preservative-free for long-term storage, 2) volume reduction during transportation, and 3) easy handling with only handshaking without solvent change or additional refinement process.”

The study team’s next endeavor will continue the work they have done using HCNFs.

Kawamura noted, “Dried HCNFs have some advantages for commercial use, such as long-term storage without preservatives and volume reduction for transportation. As a next step, we are exploring the possibility of upcycling spent coffee grounds-derived HCNFs as cosmetic and food additives.”

Journal Reference

Kanai, N., et. al. (2024) Mannan-rich Holocellulose nanofibers mechanically isolated from spent coffee grounds: Structure and properties. Carbohydrate Polymer Technologies and Applications. doi:10.1016/j.carpta.2024.100539