Reviewed by Lexie CornerAug 28 2024

Professor Takahiro Maruyama's team at Meijo University has developed a novel approach for using cobalt (Co) and iridium (Ir) nanoparticle catalysts in a liquid-phase synthesis process. This novel technique presents a viable answer to the long-standing problems of production efficiency and scalability. The findings were published in the Journal of Nanoparticle Research on June 19th, 2024.

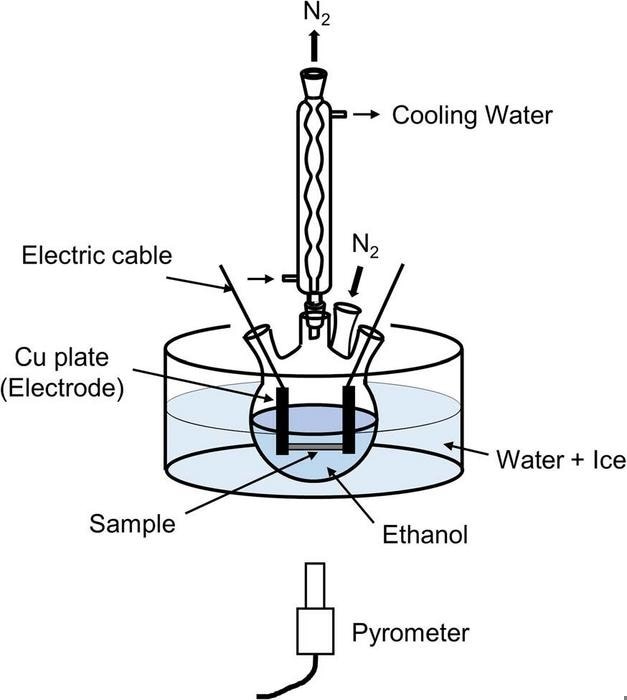

SWCNTs were grown using LPS with liquid ethanol as the feedstock. The LPS setup for SWCNT growth is schematically shown in Fig. 1. Image Credit: Takahiro Maruyama / Meijo University.

SWCNTs were grown using LPS with liquid ethanol as the feedstock. The LPS setup for SWCNT growth is schematically shown in Fig. 1. Image Credit: Takahiro Maruyama / Meijo University.

Single-walled carbon nanotubes (SWCNTs) are well-known for their extraordinary features, making them useful in various modern technologies. However, producing these nanotubes effectively and on a large scale has been consistently difficult.

Our primary objective was to develop a method that not only yields high-quality SWCNTs but also scales effectively for industrial applications. The Co and Ir nanoparticle catalysts have been instrumental in achieving these goals.

Takahiro Maruyama, Professor, Meijo University

The current study shows that the Co catalyst significantly increases the yield and structural integrity of SWCNTs during the liquid-phase synthesis process. Unlike classic gas-phase approaches, this liquid-phase approach provides more control over the reaction environment.

This innovative method results in more consistent outcomes and a more scalable process. The study also revealed that the Co and Ir catalysts remain effective after multiple usage cycles, enhancing the sustainability of the production process. Consequently, this novel approach has the potential to lower production costs, making single-walled carbon nanotubes (SWCNTs) more competitive across various markets.

Moreover, using Ir catalysts allows for precise control over the diameters and chiralities of the nanotubes, which is crucial for tailoring their electronic and mechanical properties. This fine-tuning could lead to significant advancements in applications such as high-performance transistors and sensitive sensors.

The study also provides a detailed analysis showing that SWCNTs produced using this method exhibit fewer defects than those made through conventional techniques, which is expected to improve their performance in a wide range of applications.

Maruyama added, “This advancement could enable a broader range of uses for SWCNTs in fields like electronics and energy storage, thanks to the enhanced production process.”

Furthermore, producing SWCNTs with fewer impurities may result in more efficient and reliable technologies. The increased quality of the nanotubes is projected to increase their utility in various devices, including flexible screens and cutting-edge batteries.

The study has far-reaching ramifications, including potential benefits for companies producing flexible electronics, transistors, and energy storage devices. With improved manufacturing procedures, SWCNTs may become a more realistic choice for many applications, encouraging innovation and wider acceptance.

The new technology opens the door to further exploration of different nanomaterials, potentially leading to additional technological advancements. The study also suggests that the Co-Ir catalytic system could be adapted to synthesize other nanostructures, expanding its commercial applications.

However, the study concludes that more research is needed. While the results are promising, scaling up the technique for large-scale production remains a challenge. The long-term stability and reusability of the Co and Ir catalysts must be thoroughly investigated to ensure their suitability for industrial applications. Overcoming these challenges will be essential to transitioning the laboratory findings into practical commercial solutions.

Prof. Maruyama and his team are optimistic about the potential of this catalytic system in the future.

He concluded, “We are eager to explore how this technology can be applied to other carbon nanomaterials. The opportunities are extensive, and we are only beginning to tap into their full potential.”

Journal Reference:

Maruyama, T., et. al. (2024) Liquid-phase synthesis of single-walled carbon nanotubes using Co and Ir nanoparticle catalysts. Journal of Nanoparticle Research. doi.org/10.1007/s11051-024-06047-7