In a recent article published in the Journal of Carbon Research, researchers investigated the effectiveness of low-temperature annealing techniques for polycrystalline graphite, specifically NBG-18, a material commonly used in nuclear applications.

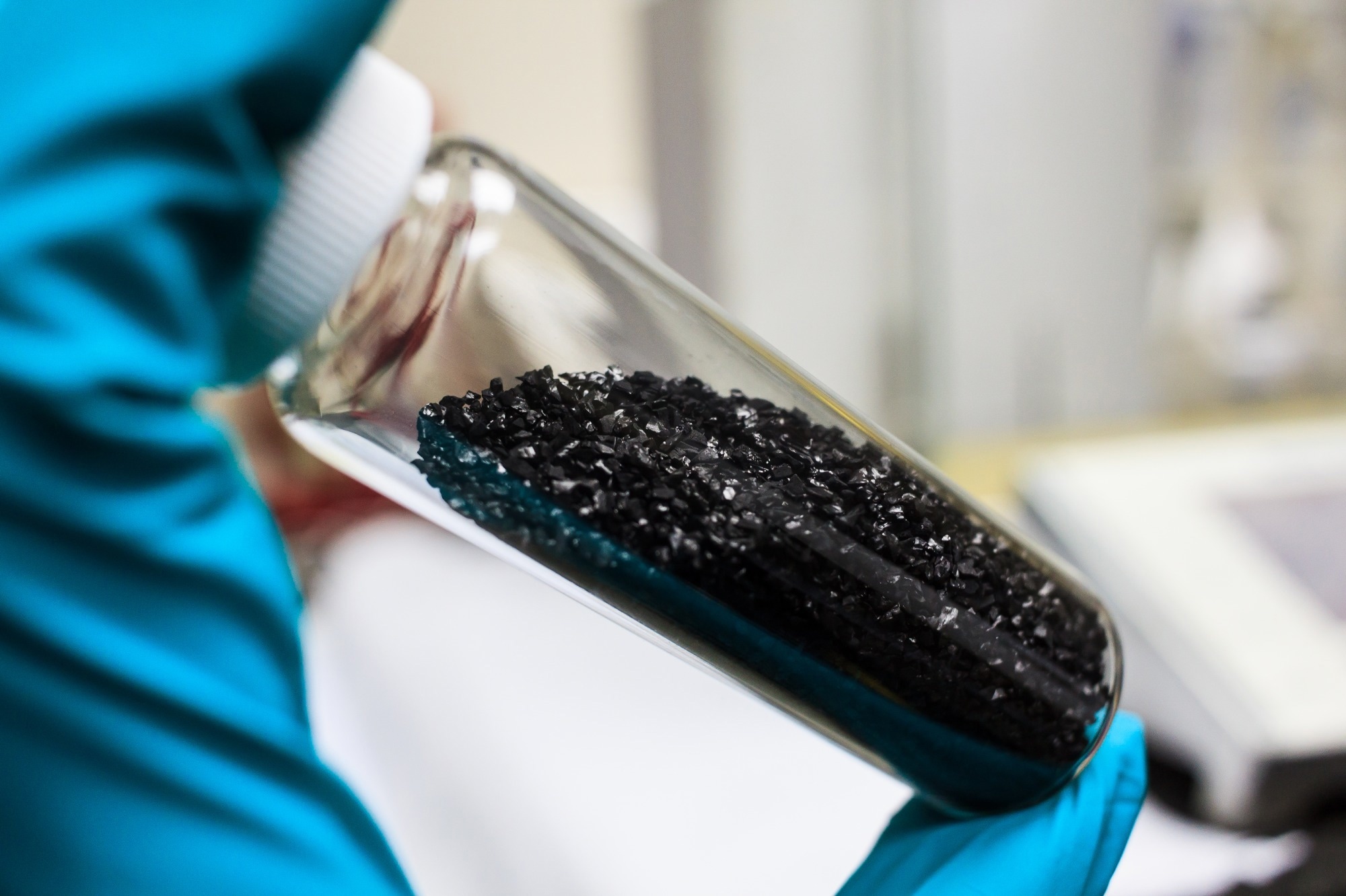

Image Credit: Eaum M/Shutterstock.com

This research introduced an innovative approach utilizing the electron wind force (EWF) to achieve defect annealing at significantly lower temperatures. The primary goal was to assess this method’s ability to reduce defect sizes and improve the material’s electrical properties, which are crucial for its performance in nuclear environments.

Background

Polycrystalline graphite is widely utilized in the nuclear industry due to its exceptional thermal and electrical properties. However, the presence of defects, which can arise from manufacturing processes and environmental factors, significantly impacts its performance.

Traditional thermal annealing methods, while effective in reducing defects, require high temperatures that can compromise the material's integrity and lead to energy inefficiencies. As the demand for more efficient and sustainable materials grows, there is a pressing need to explore alternative annealing techniques that operate at lower temperatures.

The electron wind force (EWF) method shows promise, as it mobilizes defects without the adverse effects of high-temperature treatments. This study aims to investigate the effectiveness of EWF in enhancing the properties of polycrystalline graphite, with a focus on improving performance in nuclear reactor environments.

The Current Study

Researchers used a systematic approach to evaluate the EWF technique on NBG-18 graphite. Specimens were treated with pulsed currents at densities of 25.2 A/mm² and 44.5 A/mm², while maintaining a low temperature of 28 °C. Electrical resistivity was monitored as an indicator of annealing effectiveness. Defects were characterized before and after treatment using advanced imaging methods, including X-ray computed tomography (X-CT) and Raman spectroscopy.

Micro-CT scans were performed to evaluate the size and distribution of defects within the graphite samples. The imaging process involved segmenting the tomographic images into graphite material and defects, enabling a detailed analysis of porosity and defect morphology. Additionally, nanoindentation tests were performed to evaluate changes in mechanical properties post-annealing. The experimental setup included a Berkovich tip for indentation, with a focus on minimizing standard deviation in hardness measurements.

Results and Discussion

The EWF technique led to a notable reduction in electrical resistivity. At a current density of 25.2 A/mm², resistivity decreased to 31.7 % of its initial value within just a few pulses, indicating a significant mobilization of defects. However, at 44.5 A/mm², the reduction was less pronounced, suggesting that some defects were harder to mobilize at higher densities. This behavior highlights the limitations of the current equipment and suggests that higher current densities could further enhance defect annealing.

Imaging analyses showed a significant reduction in average defect size within the submicron range, although the EWF technique was less effective at modifying larger defects, such as pores exceeding 10 microns in diameter.

The study highlighted that while EWF is highly effective for two-dimensional defects like grain boundaries, its ability to address three-dimensional defects is limited. Additionally, the findings indicated that the annealing process occurred mostly within the first few seconds of current application, in contrast to traditional thermal annealing, which requires extended exposure to high temperatures.

The study also compared the effectiveness of EWF with conventional thermal annealing methods. Similar reductions in resistivity were achieved, but only at much higher temperatures, around 700 °C, highlighting the energy efficiency of the EWF method. The integration of electrical resistance measurements and imaging techniques provided a thorough understanding of defect dynamics and the overall effectiveness of the annealing process.

Conclusion

The research demonstrated that the electron wind force technique offers a low-temperature alternative for annealing defects in polycrystalline graphite.

The significant reduction in electrical resistivity and defect size confirms the method's potential to enhance material properties without the drawbacks of high-temperature treatments. These findings suggest EWF could improve nuclear graphite performance, particularly where energy efficiency and material integrity are critical.

Future work will focus on optimizing current density, addressing larger defects, and further examining mechanical properties. This study contributes to ongoing efforts to develop more efficient material processing techniques for the nuclear industry and beyond.

Journal Reference

Liu G., Oh H., et al. (2024). Low-Temperature Annealing of Nanoscale Defects in Polycrystalline Graphite. Journal of Carbon Research 10(3):76. DOI: 10.3390/c10030076, https://www.mdpi.com/2311-5629/10/3/76