Reviewed by Lexie CornerFeb 19 2025

Research published in Matter by Rice University and collaborators reports that MAC, a material recently synthesized at the National University of Singapore, is eight times tougher than graphene.

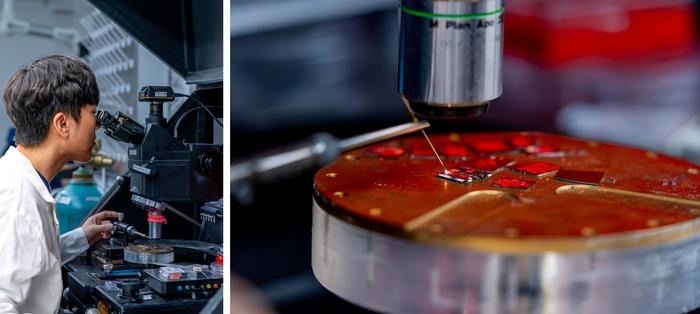

Researchers at Rice University and collaborators found that a new carbon material known as monolayer amorphous carbon is eight times tougher than graphene. Image Credit: Gustavo Raskoksy/Rice University

Researchers at Rice University and collaborators found that a new carbon material known as monolayer amorphous carbon is eight times tougher than graphene. Image Credit: Gustavo Raskoksy/Rice University

Even the strongest materials can fracture under stress, presenting a challenge for materials scientists. Graphene and other carbon-based materials exhibit high strength, but their susceptibility to rapid crack propagation makes them prone to sudden failure.

Monolayer amorphous carbon (MAC) is a newly developed carbon material with high strength and durability. Like graphene, MAC is a two-dimensional, single-atom-thick material. However, unlike graphene, which has a crystalline hexagonal lattice, MAC consists of both crystalline and amorphous regions, forming a composite structure.

The toughness of MAC is attributed to this composite structure, suggesting that a composite design approach could help mitigate the brittleness of two-dimensional materials.

This unique design prevents cracks from propagating easily, allowing the material to absorb more energy before breaking.

Bongki Shin, Study First Author and Graduate Student, Materials Science and Nanoengineering, Rice University

This development has significant implications for two-dimensional materials, which are used in applications such as wearable technology, high-capacity energy storage, advanced sensors, and improved electronic devices. However, the brittleness of these materials has limited their practical implementation. Addressing this challenge is necessary to further exploit their properties.

The resilience of 2D nanomaterials can be enhanced through two approaches: incorporating reinforcing nanostructures into thin films, referred to as extrinsic toughening, or modifying the material's internal structure, known as intrinsic toughening. The in-plane structure of MAC, consisting of crystalline regions embedded within an amorphous matrix, provided an ideal model for assessing the fracture toughness of nanocomposites.

We believe that this structure-based toughening strategy could work for other 2D materials, so this work opens up exciting possibilities for advanced materials design.

Jun Lou, Professor and Study Corresponding Author, Materials Science and Nanoengineering, Department of Chemistry, Rice University

Researchers at Rice University used in situ tensile testing within a scanning electron microscope to observe crack formation and propagation in real time. This allowed them to directly examine how the structure of the MAC nanocomposite inhibits crack propagation.

Meanwhile, a research team at the Massachusetts Institute of Technology, led by Markus Buehler, used molecular dynamics simulations to analyze the material at the atomic scale. These simulations provided insights into how the combination of crystalline and amorphous regions influences fracture energy.

This hadn’t been done before because creating and imaging an ultrathin, disordered material at the atomic scale is extremely challenging. However, thanks to recent advances in nanomaterial synthesis and high-resolution imaging, we were able to uncover a new approach to making 2D materials tougher without adding extra layers.

Yimo Han, Assistant Professor and Study Corresponding Author, Materials Science and Nanoengineering, Rice University

The study was funded by the Singapore Ministry of Education, the Singapore National Research Foundation under its Competitive Research Program, the Welch Foundation, and the United States Department of Energy.

Journal Reference:

Shin, B., et al. (2025) Intrinsic toughening in monolayer amorphous carbon nanocomposites. Matter. doi.org/10.1016/j.matt.2025.102000