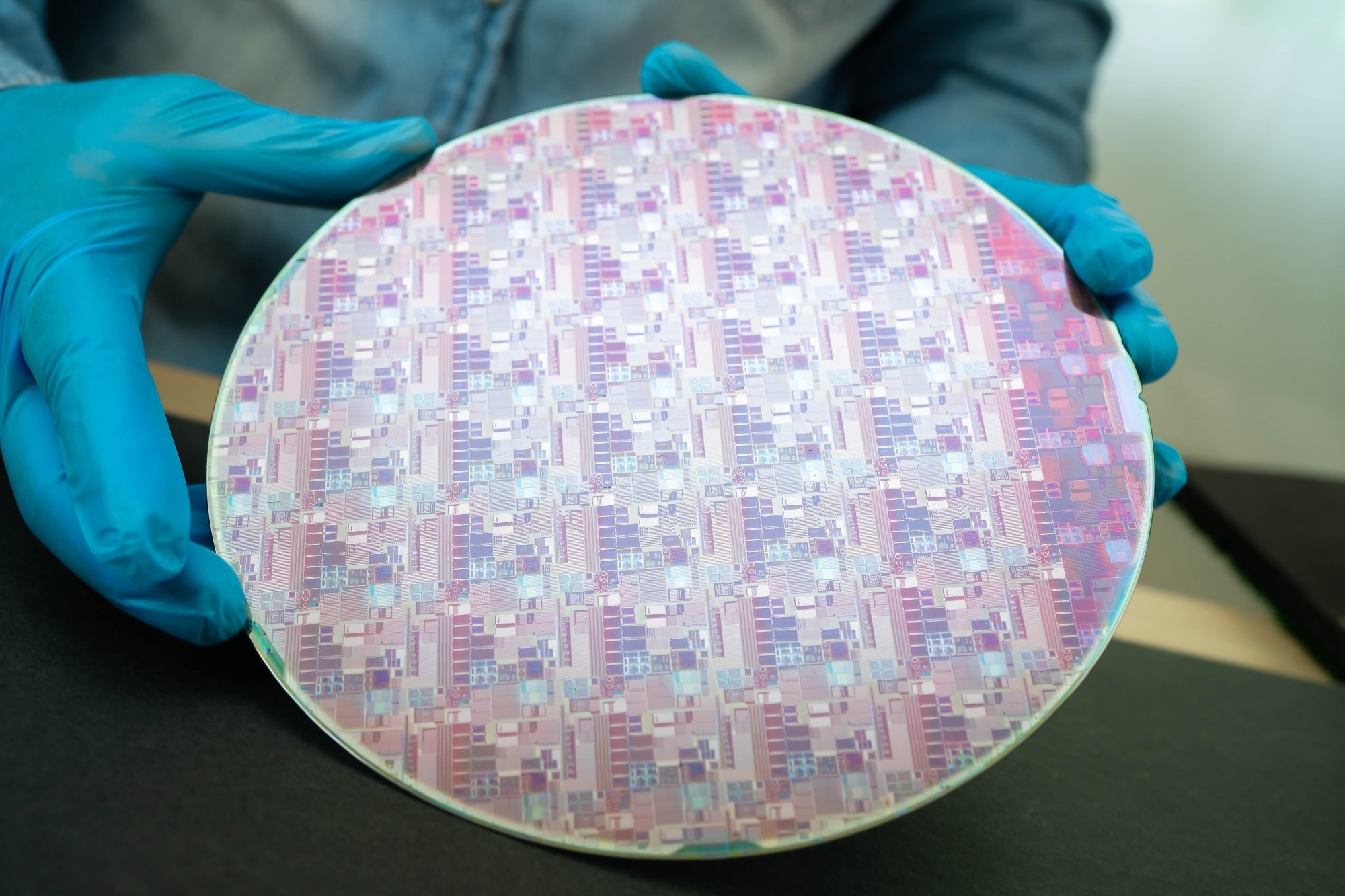

Extreme Ultraviolet (EUV) lithography is transforming semiconductor manufacturing by enabling the etching of extremely fine patterns onto silicon wafers. Utilizing light with a 13.5 nm wavelength, this technology is essential for advancing chip miniaturization beyond traditional methods.

Image Credit: superbeststock/Shutterstock.com

How Does EUV Lithography Work?

EUV Lithography is a state-of-the-art technology in chip manufacturing that uses highly energetic ultraviolet light to carve detailed patterns onto semiconductor surfaces.

It enables the production of chips with features smaller than 7 nanometers, pushing the boundaries of Moore's Law—a principle that has driven the exponential growth of computing power by doubling the number of transistors on a microchip approximately every two years.

This technology generates high-energy photons capable of exposing ultra-fine circuit patterns with resolutions below 20 nm, surpassing traditional optical lithography methods.1

EUV lithography's ability to achieve such precision is critical for producing advanced microchips that support greater density and performance in electronic devices while supporting the trend of miniaturization in the tech industry.2

Advantages of EUV Lithography

The primary advantage of EUV lithography is its ability to create extremely fine patterns on silicon wafers, which is necessary for modern semiconductor devices demanding higher performance and lower power consumption.3

Unlike traditional photolithography methods, which use longer wavelengths and struggle with miniaturization, EUV lithography enables the development of smaller, denser, and more powerful microchips. This capability is crucial in industries that require advanced processing power, such as electronics, automotive, and AI computing.4

By delivering finer patterns with greater accuracy and fewer defects, EUV lithography not only enhances chip performance but also improves manufacturing efficiency. The increased precision results in higher yields, reduced production costs, and better overall efficiency, making it a transformative technology in semiconductor manufacturing.

Challenges of EUV Lithography in Chip Production

Despite its advantages, EUV lithography presents several challenges. The process is costly and requires high maintenance, with technical demands related to light source intensity, mask defects, and environmental impacts.5

The significant investment in advanced equipment and the development of specialized materials, such as photoresists capable of handling higher photon-shot noise, further complicate its adoption.6

Technical complexities, such as the need for robust pellicles to protect photomasks and the difficulty of scaling laboratory techniques to industrial production, further complicate its adoption.

However, as these issues are addressed, EUV lithography is becoming indispensable for producing advanced processors and memory devices that power modern electronics.7

Future of EUV Lithography in Semiconductors

EUV lithography is set to become a cornerstone of semiconductor technology, driving the continued miniaturization of devices by leveraging its exceptionally short-wavelength light.8

Recent advancements are expanding the scope of EUV lithography. The introduction of high-numerical aperture (High-NA) EUV scanners is a significant development, enhancing resolution and enabling patterning down to the sub-2 nm range. This improvement is crucial for meeting the demands of future technology nodes and maintaining the pace of innovation in semiconductor design.

Additionally, progress in EUV photoresists is enabling resolutions as fine as 11 nm, with further advancements expected in the near future.3,9 These developments are essential for achieving high-volume manufacturing at advanced nodes, contributing to greater process stability and defect control, which are vital for maintaining the reliability of semiconductor production.

These technological strides also contribute to greater process stability and defect control, which are vital for maintaining the reliability of semiconductor production.

The market for EUV lithography is projected to grow from $9.4 billion in 2023 to $25.3 billion by 2028, reflecting its increasing role in semiconductor manufacturing. Emerging technologies like maskless digital EUV lithography are being explored to provide cost-effective, high-resolution patterning solutions, potentially revolutionizing integrated circuit manufacturing.10,11

Conclusion

In summary, EUV lithography represents a foundational advancement in semiconductor technology. Its ability to create extremely fine patterns on silicon wafers is crucial for the next generation of microprocessors and memory chips. As the technology continues to evolve and overcome existing challenges, it will play a transformative role in shaping the future of computing and electronic devices.

Discover More: Ultra-High Purity Gas Mixing for Improved Semiconductor Manufacturing

References and Further Reading

1. Manouras, T., et al. (2020). High Sensitivity Resists for EUV Lithography: A Review of Material Design Strategies and Performance Results. Nanomaterials. doi.org/10.3390/nano10081593

2. Ober, CK., et al. (2023). Recent developments in photoresists for extreme-ultraviolet lithography. Polymer. doi.org/10.1016/j.polymer.2023.126020

3. Katari. M. (2024) The Impact of Extreme Ultraviolet Lithography (EUVL) on Semiconductor Scaling. Journal of Artificial Intelligence General Science (JAIGS). doi.org/10.60087/jaigs.v2i1.190

4. Giannopoulos, I., et al. (2024) Extreme ultraviolet lithography reaches 5 nm resolution. Nanoscale. doi.org/10.1039/D4NR01332H

5. Liddle, AJ., Ruix, R. (2024). Novel Patterning Technologies. [Online] SPIE. Avaialble at: https://spie.org/Publications/Proceedings/Volume/12956#_=_

6. Popescu., C., et al. (2022) Recent accomplishments in EUV lithography patterning for multi-trigger resist. International Conference on Extreme Ultraviolet Lithography. doi.org/10.1117/12.2641787

7. Choi, HW., et al. (2023) Graphite Pellicle: Physical Shield for Next-Generation EUV Lithography Technology. Advanced Materials Interfaces. doi.org/10.1002/admi.202202489

8. Tian, W. (2023) Research progress of laser lithography. Journal of Physics: Conference Series. doi.org/10.1088/1742-6596/2608/1/012016

9. Develioglu, A., et al. (2023). Advancements in EUV photoresists for high-NA lithography. International Conference on Extreme Ultraviolet Lithography. doi.org/10.1117/12.2686250

10. Johnson. K., (2019) Maskless EUV lithography, an alternative to e-beam. Journal of Micro/Nanolithography, MEMS, and MOEMS. doi.org/10.1117/1.JMM.18.4.043501

11. Skyquest. (2024) Extreme Ultraviolet (EUV) Lithography Market Insights [Online] Skyquest. Available at: https://www.skyquestt.com/report/extreme-ultraviolet-lithography-market# (Accessed on 4 September 2024)

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.