The CoreAFM is the outcome of smartly integrating the core components of AFM to achieve utmost flexibility and user-friendliness. The CoreAFM is set up to conduct AFM at its best, thanks to its fundamental design approach.

A full AFM system, with an unmatched small footprint, has been created by combining an advanced flexure-guided scanner, active vibration isolation table, XYZ sample stage, camera and airflow shielding in a single all-in-one device.

The system has a 24-bit digitalized controller that was designed exclusively for the CoreAFM scanhead. The CoreAFM system includes all of the basic functionalities of recent AFM. To get the CoreAFM back in operation, all that the user needs to do is connect the controller and put in power and USB.

The Best Value Research AFM

- Integrated system with a small footprint

- Practical to handle

- Research AFM with a competitive price tag

- 33 modes and functions

In my lab at ESPCI, we study the interfacial dynamics of soft materials. Usually, a polymeric material makes up either the surrounding fluid or a surface layer and a colloid can be used as a tracer or model object interacting with the surface.

Dr. Joshua D. McGraw, Gulliver UMR 7083, CNRS ESPCI-PSL / IPGG, France

Dr. Joshua D. McGraw added, “As such, AFM in general, and colloidal probe AFM in diverse environments more specifically, is a necessity for my lab. With such applications in mind, and with a young researcher’s budget, Marco from Nanosurf’s technical sales team suggested the CoreAFM.

In addition to performing very well in air for surface topographic characterization, the instrument also performs under liquid environments and at elevated temperatures using a colloidal probe. This latter functionality is possible thanks to the CoreAFM’s impressive modularity. An extensive library of accessories and functional add-ons, all with a good value for money, give me the flexibility to upgrade the instrument to suit my research needs as they arise.

Dr. Joshua D. McGraw, Gulliver UMR 7083, CNRS ESPCI-PSL / IPGG, France

“Lastly, the technical team at Nanosurf is very available for troubleshooting support when the need arises, and have always helped to solve problems efficiently. Given the instrument’s value-for-money, the personal and efficient technical support, the instrument’s performance and modularity, I would not hesitate to recommend the CoreAFM,” stated Dr. Joshua D. McGraw.

Seamlessly Extendable Functionality

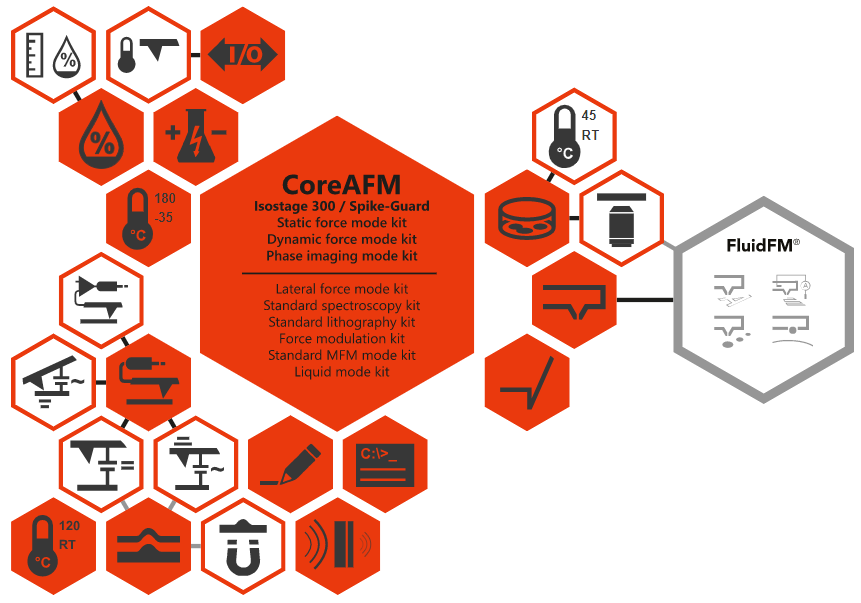

The CoreAFM is an ideal choice of instrument for applications ranging from materials research to life science and electrochemistry, with 32 standard and optional modes and entirely compatible add-ons. The functionality of the CoreAFM system may be effortlessly expanded, starting from its basic system. Sample heating, scripting, environmental control and other advanced AFM modes and features may be readily added to the CoreAFM. See the overview image for further information and dependencies.

Image Credit: Nanosurf AG

Easy Setup and Handling

Check out how simple it is to set up and use the CoreAFM. Watch the video for a demonstration of the system’s major functions as well as a quick tutorial on how to take a measurement with it.

Nanosurf CoreAFM Overview and Tutorial

Video Credit: Nanosurf AG

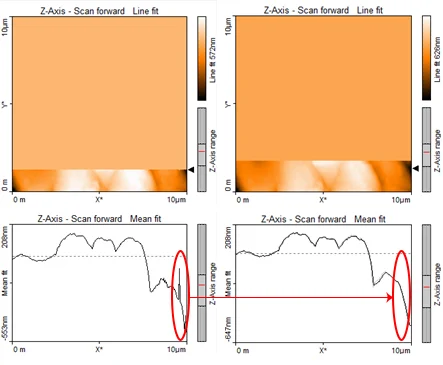

Spike-Guard

The innovative Spike-Guard, which avoids glitches during imaging, reflects the Isostage’s deeper system integration. Despite the fact that the Isostage is an active vibration isolation technology, glitches might arise if distortions are extreme. Spike-Guard identifies these abnormalities and rescans the line to ensure that the image is distortion-free.

Image Credit: Nanosurf AG

Powerful and Versatile

High-resolution XYZ driving of the 100 × 100 × 12 μm scanner is ensured by state-of-the-art electronics with 24-bit ADC and DAC, allowing for low-noise force detection restricted only by the cantilever.

The CoreAFM is the instrument of choice for applications ranging from materials research to life science and electrochemistry, with 32 standard and optional modes and completely compatible add-ons. The capability of the CoreAFM system may be effortlessly expanded, from its basic system.

A closed scanner compartment features acoustic and air current isolation, while sample stage positioners still allow you to adjust your sample.

Image Credit: Nanosurf AG

When the scanner compartment is opened, it provides access to the scanner and sample stage, e.g. to place a new sample for measurement.

Image Credit: Nanosurf AG

CoreAFM Imaging Modes

The above discussion reveals the modes that the instrument is capable of. Some modes may involve the use of extra hardware or software options. Please see the brochure for further information.

Standard Imaging Modes

- Dynamic force mode (Tapping mode)

- Lateral force mode

- Phase imaging mode

- Static force mode

Magnetic Properties

- Magnetic force microscopy

Electrical Properties

- Electrostatic force microscopy (EFM)

- Conductive AFM (C-AFM)

- Kelvin probe force microscopy (KPFM)

- Piezoelectric force microscopy (PFM)

Mechanical Properties

- Force modulation

- Force spectroscopy

- Unfolding and stretching

- Electrochemical AFM (EC-AFM)

- Force mapping

- Stiffness and modulus

- Lithography and nanomanipulation

- Adhesion

Included Measurement Modes

Static force, phase imaging, dynamic force, MFM, force modulation, lateral force, standard lithography and standard spectroscopy are all available right out of the box with the CoreAFM. CoreAFM mode kits, on the other hand, can improve the user's measuring experience.

Included Standard Mode Kits

The static force mode kit, phase-imaging mode kit and dynamic force mode kit are all included by default with the CoreAFM to get customers started right away. A mode kit may comprise samples, appropriate cantilevers, accessories or a mix of these items, depending on the measurement mode.

Additional Standard Mode Kits

The standard spectroscopy kit, standard MFM mode kit, standard lithography kit, lateral force mode kit, standard liquid mode kit and force modulation mode kit are additional standard-level mode kits that may be purchased individually.

System Specifications

Table 1. Scanner. Source: Nanosurf AG

| . |

. |

. |

| Max. scan range (XY) |

100 µm(1) |

<5 nm flatness |

| Max. height range (Z) |

12 µm(2) |

closed loop |

| Detector noise (RMS) |

typ. 60 pm |

max. 100 pm |

| Sensor noise (RMS) |

typ. 180 pm |

max. 250 pm |

| Dynamic noise (RMS) |

typ. 40 pm |

max. 70 pm |

| Static noise (RMS) |

typ. 100 pm |

max. 200 pm |

(1) Manufacturing tolerances ±5%

(2) Manufacturing tolerances ±10%

Table 2. Controller. Source: Nanosurf AG

| . |

. |

. |

| Scan control and inputs |

24-bit ADC/DAC |

200 kHz |

| Digital lock-in (2×) |

16-bit ADC/DAC |

20 MHz |

| User in/out, Excitation in |

24-bit ADC/DAC |

5 MHz, 10 V |

| Digital sync |

2-bit line/frame sync out |

5 V, TTL |

| Thermal tuning |

10 Hz – 2 MHz |

|

| FPGA, 32-bit CPU, 256 MB RAM |

programmable |

USB 2.0 |

Table 3. Cantilever. Source: Nanosurf AG

| . |

. |

| Width |

min. 20 μm |

| Length |

min. 40 μm |

| Reflective coating |

Reflective coating recommended |

| Liquid measurements |

Yes, with gold coating |

| Alignment grooves |

Required by default

Special cantilever holders without alignment grooves are available |

Resonance frequency

dynamic mode |

<4 MHz |

| Cantilever shape |

Single rectangular cantilevers and multilever cantilevers (depending on scan head version and cantilever holder) |

| Chip thickness |

300 μm, 500 μm or 600 μm depending on cantilever holder |

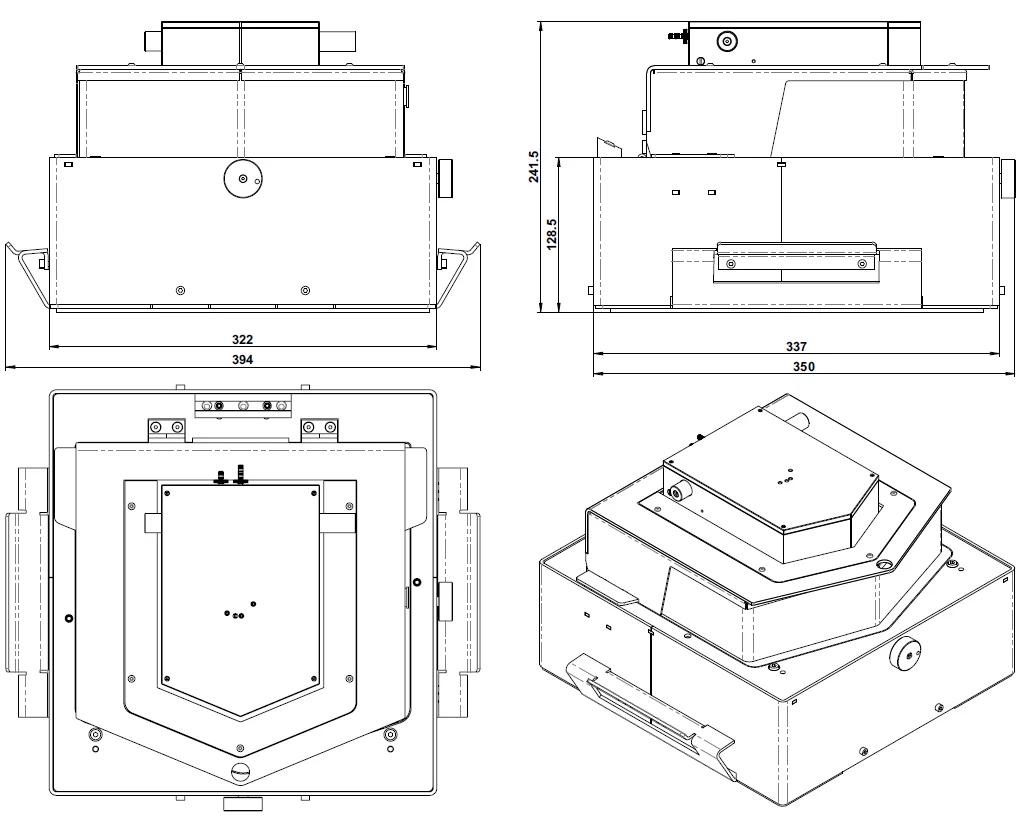

System Dimensions

Image Credit: Nanosurf AG