A recent study published in the journal Polymers focuses on the preparation, properties, and industrial applications of polymer nanomaterials reinforced with nanoclay.

Study: An Investigative Study on the Progress of Nanoclay-Reinforced Polymers: Preparation, Properties, and Applications: A Review. Image Credit: losmandarinas/Shutterstock.com

As a result of their remarkable qualities and their ever-increasing use in a wide range of applications, nanoclay-reinforced polymers have achieved significant global interest in both industrial and academic research in recent years.

What are Polymer Nanocomposites?

Polymer nanocomposites are an important class of inorganic-organic nanomaterials that have inorganic nanoparticles dispersed throughout the substrate of organic polymers. The interfaces between the fillers and the polymer matrices in nanocomposites are considerably larger than in traditional composite materials made of micrometer-sized additives, and thus these nanocomposites have far better material characteristics.

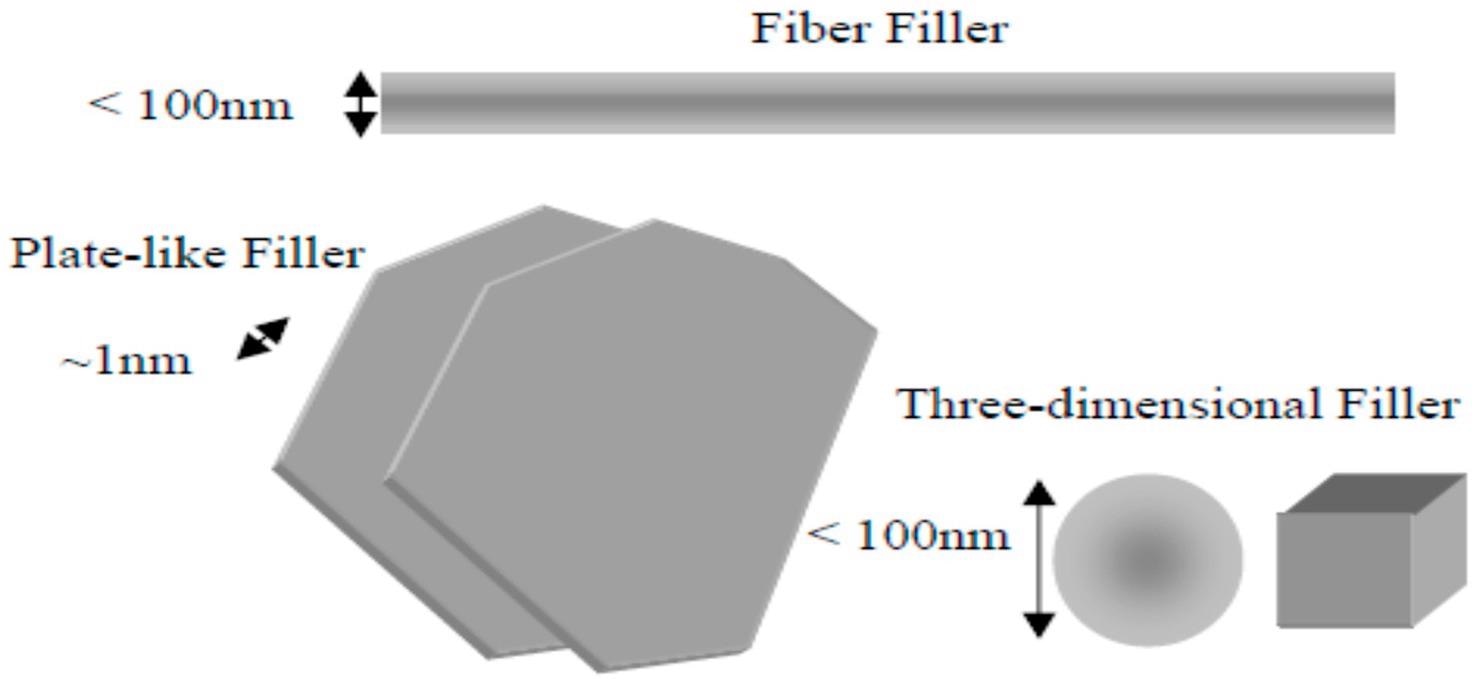

Schematic illustration of nanoscale fillers.© Abulyazied, D. E., & Ene, A. (2021).

Although nanoparticles come in a range of forms and configurations, they may be classified into three broad categories. Nanoparticles in one dimension (1D), such as nanoclay and graphene, are stacked particulates with a diameter of 1 nm and a span of hundreds or even thousands of nanometers. Two-dimensional (2D) nanomaterials include carbon nanowires and nanotubes, which have a diameter of at least 100 nm and an area ratio of less than 100. Three-dimensional (3D) nanoparticles, such as hemispheric silicon, nano aluminum, and nano titanium oxide, are agglomerated nanoparticles having a maximum size of less than 100 nm.

Although many nanocomposites, including carbon nanotubes (CNTs) and graphene, have been examined for use as fillers, the most commonly used materials are clay-reinforced nanoparticles. This is because these nanoclay particles are abundant in nature and are extremely cost-effective.

Structure of Nanoclay

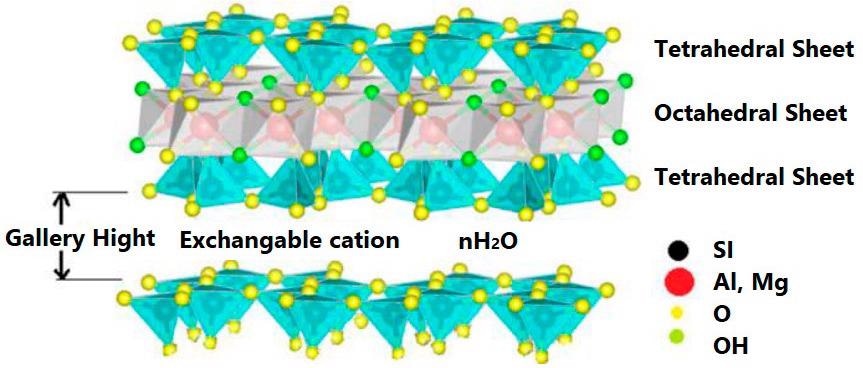

Nanoclay is composed of silica nanoparticles that include trace amounts of metal oxides such as rare metals, alkaline metals, limestone, metallic oxides, and organic materials. Clay components are classified into two categories depending on the arrangement of the overlapping sheets of silica and aluminum oxide units: (i) 2:1 clay (smectite and vermiculite); and (ii) 1:1 clay (kaolinite).

Smectite silicates have a high surface area owing to their distinctive deposition activity, which makes them especially valuable and effective as fiber reinforcements for polymeric nanocomposites.

Structure of 2:1 layered silicate.© Abulyazied, D. E., & Ene, A. (2021).

Other clay minerals (kaolinite) are often not used in polymeric composites due to their ineffective deposition, abrasion capabilities, and difficulty in layering individually. Due to the higher charge distribution of the layers, hydrolysis of intermediate positive ions and infiltration of polymer chains into the clay layers is extremely difficult, which makes these 1:1 clay minerals unsuitable for industrial applications.

Properties of Nanoclay-Reinforced Polymers

Numerous industries are interested in polymer–clay nanocomposites owing to their significant economic advantages, such as reduced weight due to the decreased clay concentrations. Additionally, these materials exhibit remarkable physical qualities such as high rigidity, improved permeability behavior as a consequence of decreased water and oxygen molecule kinetic movement, and enhanced thermal properties such as fire resistance and heat deformation temperature (HDT).

Industrial Applications

Their extraordinary properties make polymer–clay nanoparticles very appealing for a variety of industrial applications, from foods and electronic manufacturing to robust, heat-resistant car components. Additionally, polymeric clay nanocomposites are suitable for application in lithium-ion batteries (LIBs). Reusable LIBs are recognized as one of the most effective and cheap energy storage devices in communication equipment and electric cars due to their small size, increased energy concentration, and steady life cycle performance.

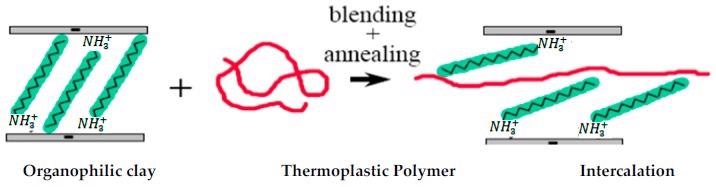

Melt blending technique for the preparation of polymer/clay nanocomposites. © Abulyazied, D. E., & Ene, A. (2021).

Polymeric gel electrolytes (PGEs) with 0–4% organic clay have shown remarkable electrical and chemical characteristics suitable for lithium-ion battery applications. Organic clay considerably improves electric conduction and increases the number of lithium cations transferred, resulting in a higher electrolytic battery charge and discharge efficiency in lithium-ion fuel cells.

Conclusion and Future Perspectives

Among the several renowned nano-technological products, polymer–clay nanocomposites have emerged as the most significant in recent times. By choosing the suitable substrate, modified organic clay, and manufacturing processes, polymeric nanoclay composites can be formed in a facile manner.

Although polymeric–clay nanomaterials have a wide range of vital applications in a variety of industries, their commercialization faces plenty of technological and economic difficulties. These include impact strength, complex commercial synthesis, and techniques for dispersing and evaluating nanoclay in polymeric composites. Another impediment to the development of innovative nanoclay technology is a lack of investment in state-of-the-art equipment and academic research organizations.

Continue reading: Innovations in Nanocomposites: A Future Outlook.

Reference

Abulyazied, D. E., & Ene, A. (2021). An Investigative Study on the Progress of Nanoclay-Reinforced Polymers: Preparation, Properties, and Applications: A Review. Polymers, 13(24), 4401. Available at: https://www.mdpi.com/2073-4360/13/24/4401

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.