Atomic force microscopy (AFM) is a powerful technique that aids in imaging surfaces of nanostructures, structures whose dimension ranges between 1nm and 100nm.

Image Credit: Georgy Shafeev/Shutterstock.com

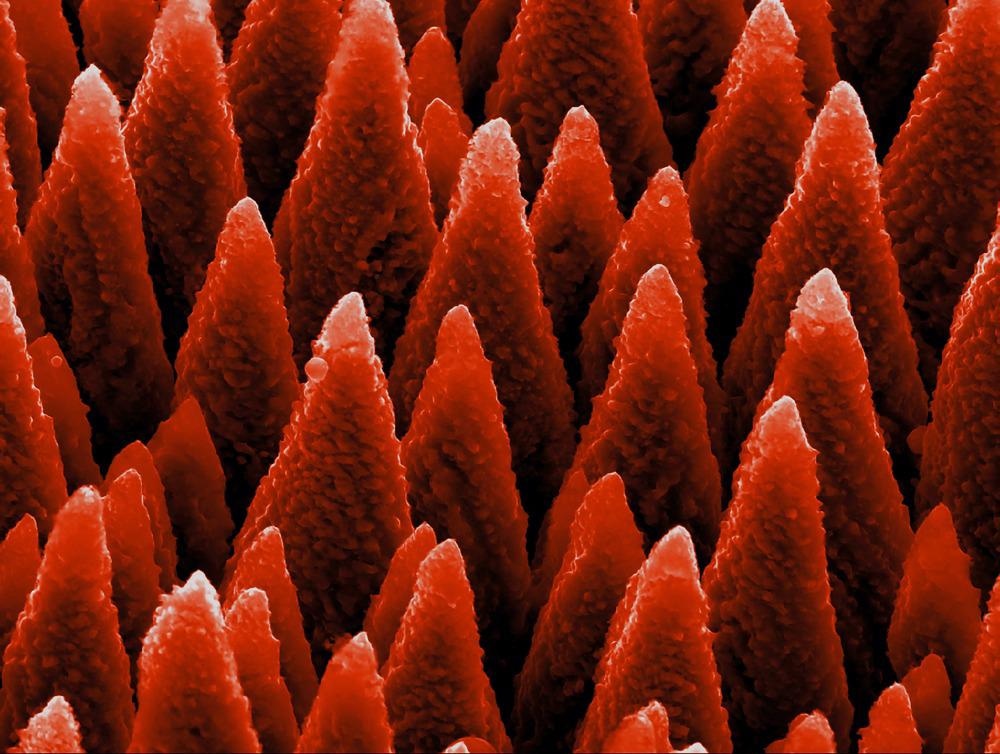

Some of the common types of nanostructures are nanopillars, cylindrical nanotubes, nanowires, and nanospheres. The mechanical properties of a component are dependent on the type of nanostructure or patterns of arrangement of nanomaterials on the surface of a material.

Importance of Nanostructures Analysis

It is important to accurately characterize nanostructures because it helps define the mechanical properties of a material.

The optimized pattern of each nanopillar is a fundamental aspect of many applications. For instance, nanoparticles are known to possess antibacterial properties. In this context, the stiffness of nanostructures determines how well these structures could enter and disrupt bacterial cell walls.

Moreover, nanostructure analysis of biomolecules using AFM has been used to detect various diseases like Parkinson’s disease.

Several neurological disorders are caused by the aggregation of proteins into fibrillar structures called amyloid. In Parkinson’s disease, a high concentration of fibrillar aggregates is found in the brain of the patients.

Researchers utilize the differential contrast mode of high-resolution AFM to study fibrillar structures formed by the wild-type alpha-synuclein protein. Data offered by AFM analysis showed the depths of all protein mutants, the detailed morphology, and the mechanical properties of fibrils.

Atomic Force Microscopy

Atomic-force microscopy is a powerful tool that facilitates imaging at a subnanometer resolution. AFM measures a variety of tip-surface interactions based on the separation between the tip and the sample.

When the distance between the sample and the tip is small (0.1 nm), the tip experiences interatomic forces. At a longer length, i.e., up to 10 nm, the tip experiences van der Waals forces, and when the distance is even larger, i.e., 100-500 nm above the surface of the sample, the van der Waals forces decrease rapidly and become negligible.

However, at larger distances, long-range electric, magnetic and capillary forces remain significant, and these can be probed. A better understanding of these interactions would enable researchers to develop improved functional surfaces via optimizing the nanoscale patterning and manipulating material surfaces.

The AFM offers three-dimensional (3-D) imagining, meaning it can provide an image from the X, Y, and Z-axis. Researchers stated that processing AFM data using improved software applications would provide quantitative evidence from individual nanoparticles as well as between groups of nanoparticles. This analytical tool can measure the surface textures and render morphological characteristics of individual nanoparticles.

Generally, AFM is used for the characterization of nanomaterials. This is because it provides evidence on surface morphology, compositional mapping of heterogeneous samples, and evaluation of mechanical, electric, magnetic, and thermal properties. In combination with scanning electron microscopy, AFM is used to study the deep trenches profiles of nanomaterials ranging between tens and hundreds of nanometres in dimensions. This analysis is extremely important for the manufacturing of semiconductors.

Improvements in Atomic Force Microscopy for Nanostructure Analysis

Scientists have advanced the primary AFM and have subsequently developed critical-dimension atomic-force microscopy (CD-AFM) and Traceable atomic-force microscopy (T-AFM).

CD-AFM is used to study nanostructures’ sidewall roughness, angle, and nanoscale dimension. T-AFM is equipped with displacement interferometry and is used to quantify nanoscale structures.

Sometimes nanoparticles get accidentally attached to the probe, resulting in the development of images with reduced resolution. It mainly occurs when nanoparticles are not firmly attached to a flat surface while scanning is conducted in contact mode. Researchers created AFM based on contact mode imaging (CMI) or CFM (crystal sensing) to overcome this shortcoming.

For specific samples, fixing nanoparticles on a sticky substrate within a dry or liquid medium has been recommended. Microscopists, Tacky Dot slides, and TempFix are used in this regard.

Additionally, another AFM advancement has been the development of force spectroscopy imaging (FSI) that helps determine mechanical characteristics of nanostructures without using other microscopic techniques such as scanning electron microscopy.

Analysis of Nanopillars Using CMI and FSI based Atomic Force Microscopy

As stated above, both CMI and FSI are well-established AFM techniques with multiple applications. CMI is predominantly used to characterize the morphology of a surface at a nanoscale dimension, whereas FSI techniques associated with Bruker systems are applied to conduct nanoindentation of a sample. The FSI technique is also used to measure the elastic modulus of both hard and soft nanomaterials and characterize biomolecules.

While analyzing nanopillars, both techniques assist in scanning the sample many times in CMI or FSI, by gradually raising the value of the force applied to the nanopillars until they shatter.

Both methods do not require any modification of the sample, but these can quantify the elastic properties of the nanopillar or their breaking strength.

Predominantly, these methods are effectively used to analyze polymeric nanopillars developed by two-photon polymerization and platinum-carbon nanopillars fabricated by electron beam induced deposition. Besides elastic modulus, CMI and FSI can also measure the stiffness, the maximum displacement, lateral force, highest stress, and the adhesion force of the nanopillars.

Scientists have validated both techniques by using the elastic modulus value from the Quantitative Imaging mode. Researchers have proved that these methods can accurately measure nanostructures, with their main advantages being that they are easy to perform and no sample modification is required. Furthermore, these methods can measure specimens under wet conditions, which is extremely useful to study living cells.

Continue reading: The Benefits of AFM for Nanoparticle Research.

References and Further Reading

Angeloni, L. et al. (2021) Mechanical characterization of nanopillars by atomic force microscopy. Additive Manufacturing. 39. 101858. Available at: https://doi.org/10.1016/j.addma.2021.101858

Dixson, R. (2018) Tip on Tip Imaging and Self-Consistent Calibration for Critical Dimension Atomic Force Microscopy: Refinements and Extension to Second Lateral Axis, Journal of Micro/Nanolithography, MEMS, and MOEMS. Available at: https://doi.org/10.1117/1.JMM.17.4.044001

Segers-Nolten, I. et al. (2007) Quantitative characterization of protein nanostructures using atomic force microscopy. 29th Annual International Conference of the IEEE Engineering in Medicine and Biology Society. Available at: http://dx.doi.org/10.1109/IEMBS.2007.4353874

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.