Bettersize Instruments’ BeVision D2 efficiently analyzes the size and shape of dry, high-flowability granules or powders. The D2 instrument can measure tens of thousands of particles within three minutes.

The BeVision D2 combines a precise telecentric lens with a high-speed camera, allowing it to efficiently analyze the size and shape of particles ranging from 30 μm to 10,000 μm.

The BeVision D2 offers an array of features and benefits, including:

- A wide measurement range of 30 µm to 10,000 µm

- Twenty-four particle size and shape parameters are available

- High sample throughput of 10,000 particles measured within three minutes

- Exceptional reproducibility

- All results are fully compliant with ISO 9276-6

- Operation can be fully automated

- Comprehensive evaluation via powerful software

- Results are comparable with sieving

BeVision D2 | A Precise Vision of Particles

BeVision D2 | A Precise Vision of Particles. Video Credit: Bettersize Instruments

Benefits of the Dynamic Image Analysis Method

Using dynamic image analysis, it is possible to capture an image of particles, identify the particles within the image, and measure their size and shape. Each step of the process is simple and easy to understand.

Because dynamic image analysis provides a direct view of particles, it is possible to analyze their shape and size effectively.

Once the image analysis method confirms the size and shape of every individual particle present in the image, these can be summed up to form a statistic that provides accurate details of particle size or shape distribution.

Dynamic image analysis provides several other advantages.

- Efficiency: Higher measurement efficiency is ensured by the continuous particle flow passing through the measurement zone.

- Oversized Particle Sensitivity: Dynamic image analysis makes estimating the size of oversized particles possible.

- Reliable Results: Statistical significance of measurement results is ensured by maximizing the number of measured particles.

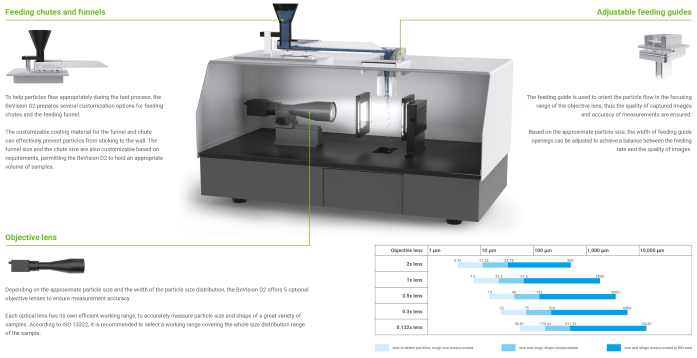

BeVision D2 Hardware: Guaranteed Accuracy and Efficiency

The BeVision D2 features a comprehensive range of hardware, allowing it to measure the size and shape of particles across a wide range of applications.

Selecting the most appropriate hardware for the sample’s material properties can help measure particle size and shape with optimal efficiency and accuracy.

Image Credit: Bettersize Instruments

Measurable Particle Size and Shape Parameters

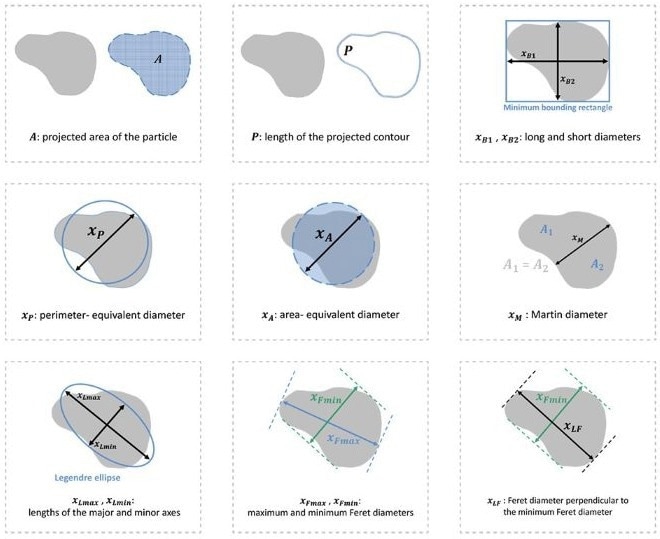

The BeVision D2 can measure several useful size and shape parameters. These include:

Size Parameters

- Equivalent diameters; for example, area-equivalent diameter and perimeter-equivalent diameter

- Legendre ellipse; for example, minor and major axes

- Feret diameters; for example, maximum and minimum Feret diameters and XLF (“length”)

- Martin diameters; for example, minimum and maximum Martin diameters

Image Credit: Bettersize Instruments

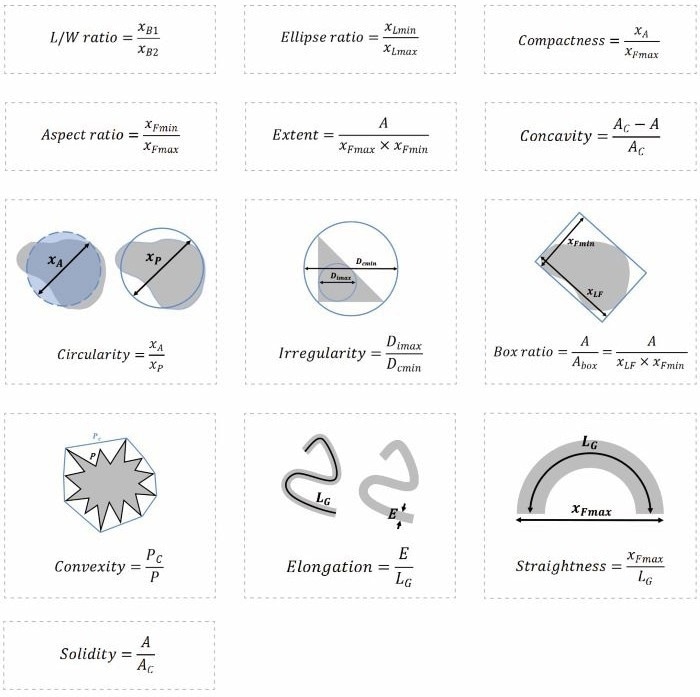

Shape Parameters

- Size difference in two directions; for example, L/W ratio, aspect ratio, and ellipse ratio

- Round-likeness and rectangle-likeness, for example, irregularity, compactness, circularity, extent, and box ratio

- Contour concavity; for example, concavity, convexity, and solidity

- Elongated particle measurements, for example, elongation and straightness

Image Credit: Bettersize Instruments

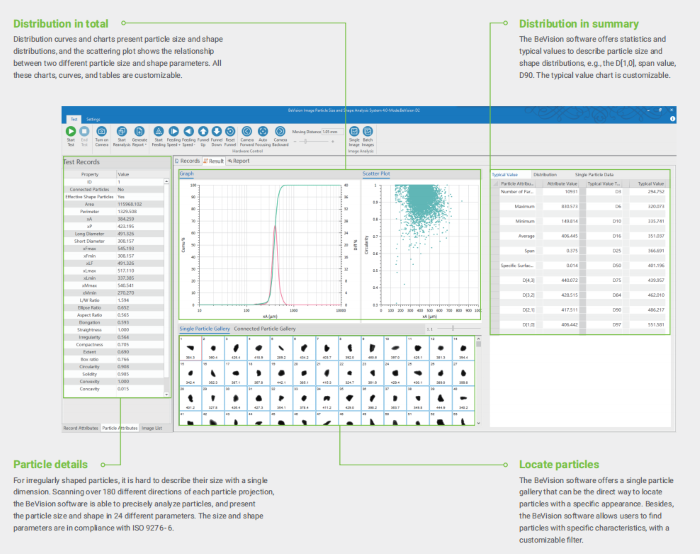

BeVision Software: Visualized Insights

Image Credit: Bettersize Instruments

Applications

The BeVision D2 is well suited to applications such as ceramics, automotive, mining and minerals, surface cleanliness, metal powders, paints, inks, coatings, abrasives, and agriculture.

Image Credit: Bettersize Instruments

Specification

Source: Bettersize Instruments Ltd.

| BeVision D2 |

| General |

| Measuring principle |

Dynamic image analysis method |

| Parameters |

Particle size, shape, and number |

| Measurement performance |

| Measuring range |

30 – 10,000 μm |

| Typical measurement time |

1 to 3 min * |

| Number of size / shape classes |

100 (user adjustable) |

| Special functions |

SOP settings, automatic tests, analysis of saved images |

| Main device |

| High-speed CCD camera |

Up to 120 images per second |

| Light source |

White LED stroboscopic parallel light source |

| System parameters |

| Dimensions (L × W × H) |

61.0 × 35.0 × 44.0 cm |

| Weight |

26 kg |

| Supply voltage |

100 / 240 V, 50 / 60 Hz |

| Software |

| Conformity |

ISO 13322, ISO 9276 |

| Reports |

Customizable reporting |

| * Sample and sample preparation dependent |