Bettersize Instruments’ BeVision M1 automated static image analyzer is an automated image scanning system suited to applications involving cleanliness analysis of particulates found on filters.

The BeVision M1 is equipped with a programmable motorized stage, metallurgical microscope, auto-focus function, and high-resolution CMOS. These features allow the instrument to capture and recognize each particle in a sample, automatically stitching the individual images to create a larger overview image.

The BeVision M1 is an integral part of surface cleanliness measurements. Its many features and benefits include:

- A wide measurement range of 1 µm to 10,000 µm

- A high-speed CCD camera

- Results compliant with ISO 9276-6

- Twenty-four different particle shape and size parameters

- Highly reproducible results

- Powerful software eases workload

- An automatic sample stage that offers high position accuracy

How to Install and Operate BeVision M1

Video Credit: Bettersize Instruments Ltd.

Advantages of Using the Image Analysis Method

Every step of image analysis is easy to understand; from directly capturing an image of particles and identifying them, to measuring their shape and size.

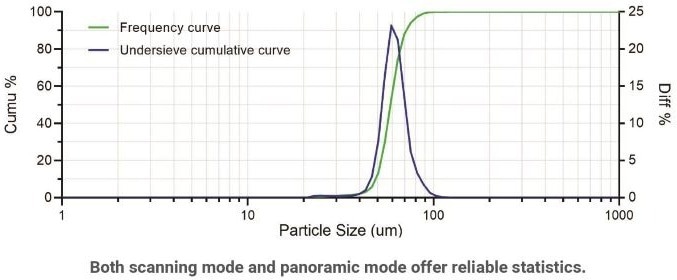

This data can be summed up in statistical form to provide an accurate and detailed distribution of particle shape or size.

Using static image analysis offers even more specific benefits. High-quality particle images can be obtained via static image analyzers due to their use of specialized precision microscopes and high-resolution cameras.

The sensitivity of this method means it is possible to measure undersized particles.

Only a small sample volume is required to obtain a measurement; for example, a few micrograms of powders or a few drops of emulsions.

The BeVision M1 can be used in scanning or panoramic mode.

Using the BeVision M1 in Scanning or Panoramic Mode

Scanning Mode

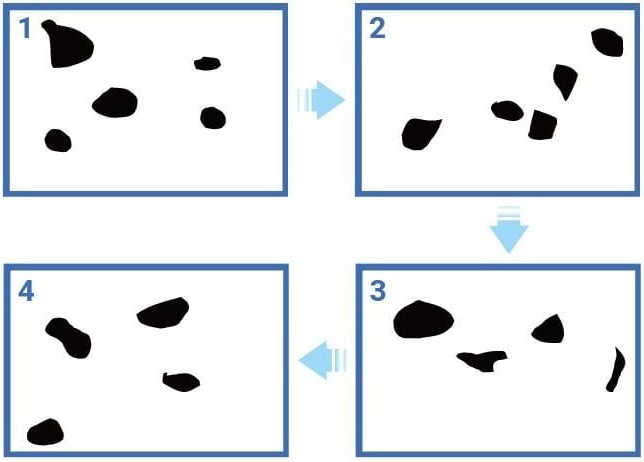

The BeVision M1’s scanning mode works by first capturing an image and then analyzing it while moving to the next stage. After capturing the next image (once the stage has reached a new position), this next image is analyzed, and the process is repeated.

The BeVision software can also display real-time results during the scanning process. The instrument’s scanning mode is widely used in a range of industries due to its efficiency and reliability.

Image Credit: Bettersize Instruments Ltd.

When compared to manual testing, this automatic scanning process offers greater efficiency as it performs the image capturing and stage moving processes simultaneously. This scanning mode can also analyze a large number of particles in one test, giving added weight to the statistical significance of the results.

Image Credit: Bettersize Instruments Ltd.

Panoramic Mode

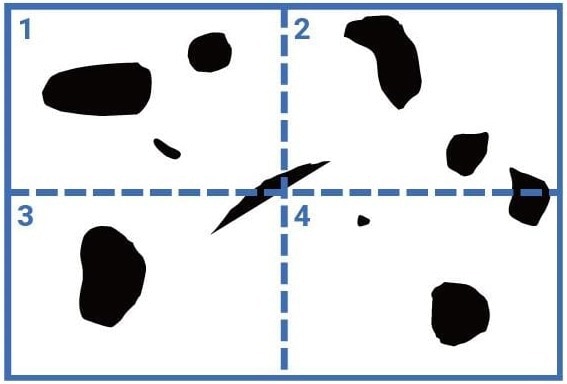

The BeVision M1’s panoramic mode involves stitching a series of separate images into a single panorama before carrying out any analysis.

A panorama facilitates the easy measurement of the total number of particles in the region as well as the size and shape of every particle. This is the case even when the particle is oversized. The automotive and pharmaceutical industries are two sectors where an accurate particle number is of vital importance.

Panoramas obtained by utilizing the BeVision M1 will record all particles dispersed in a region at the millimeter level and will retain their shape details. Clear panoramas assist in the accurate counting of particles in the macro-region. They also allow for the analysis of the shape and size of particles without any leftovers.

Image Credit: Bettersize Instruments Ltd.

Measurable Particle Size and Shape Parameters

Size Parameters

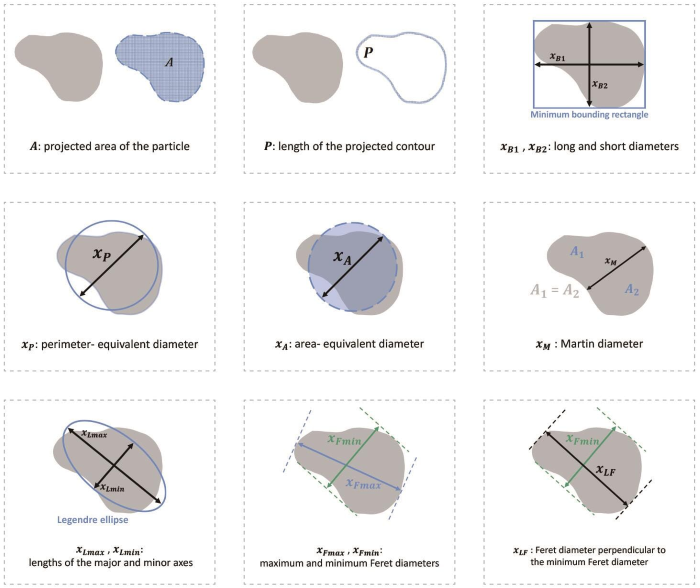

The BeVision M1 can accommodate a wide range of size parameters, including:

- Feret diameters; for example, maximum and minimum Feret diameters, and XLF (“length”)

- Equivalent diameters; for example, perimeter-equivalent diameter, and area-equivalent diameter

- Legendre ellipse; for example, the minor and major axes

- Martin diameters; for example, maximum and minimum Martin diameters

Image Credit: Bettersize Instruments Ltd.

Shape parameters

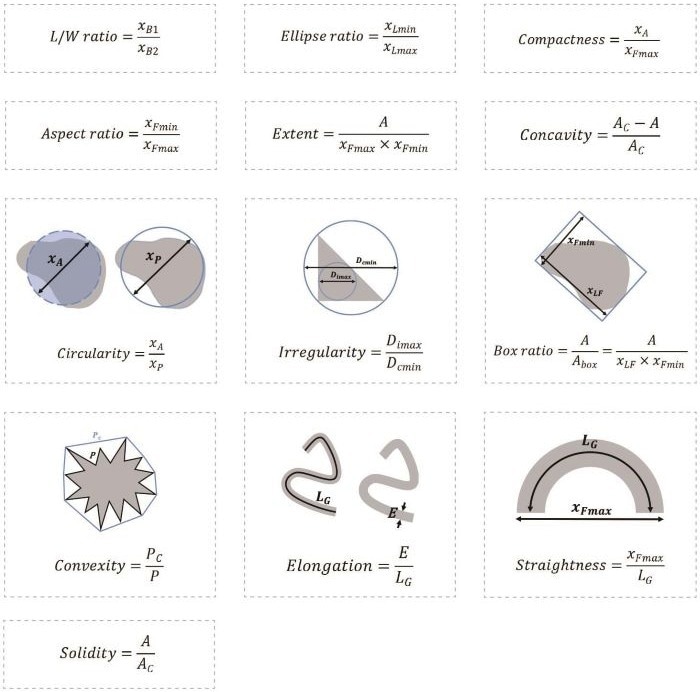

The BeVision M1 can also accommodate a wide range of shape parameters, including:

- Size difference in two directions; for example, aspect ratio, ellipse ratio, or L/W ratio

- Contour concavity; for example, concavity, convexity, or solidity

- Elongated particle measurements; for example, straightness and elongation

- Round-likeness and rectangle-likeness; for example, circularity, compactness, extent, irregularity, or box ratio

Image Credit: Bettersize Instruments Ltd.

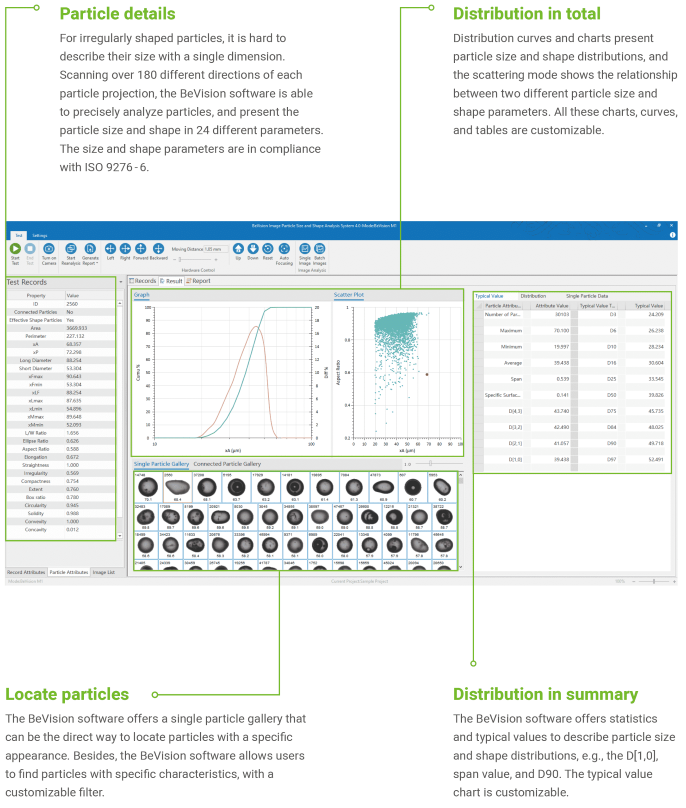

BeVision Software: Visualized Insights

Image Credit: Bettersize Instruments Ltd.

Applications

The BeVision M1 is suitable for use in various applications, including ceramics, automotive, mining and minerals, metal powders, paints, inks, coatings, surface cleanliness, abrasives, and agriculture.

Image Credit: Bettersize Instruments Ltd.

Specification

Source: Bettersize Instruments Ltd.

| BeVision M1 |

| General |

| Measuring principle |

Static image analysis method, automatically scanning |

| Parameters |

Particle size, shape, and number |

| Measurement performance |

| Measuring range |

1 – 10,000 μm |

| Typical measurement time |

3 to 5 min * |

| Number of size/shape classes |

100 (user adjustable) |

| Special functions |

SOP settings, analysis of saved images |

| Main device |

| Optical lens |

4 ×, 5 ×, 10 ×, 20 × (with 40 × digital magnification) |

| Camera |

Up to 120FPS |

| Light source |

Halogen lamp, Köhler illumination |

| Stage scanning range |

55 × 55 mm |

| System parameters |

| Dimensions (L × W × H) |

35.0 × 65.0 × 67.0 cm |

| Weight |

18.7 kg |

| Supply voltage |

100 / 240 V, 50 / 60 Hz |

| Software |

| Conformity |

ISO 13321, ISO 9276, ISO 16232, ISO 4406 |

| Reports |

Customizable reporting |

| * Sample and sample preparation dependent |

Source: Bettersize Instruments Ltd.

| BT - 910 dry powder dispersion module |

| Dimensions (L × W × H) |

23.5 × 16.5 × 26.6 cm |

| Weight |

4.3 kg |

| Supply voltage |

100 / 240 V, 50 / 60 Hz |

| Dispersion air pressure |

≤ - 60 kPa |