The SurPASS 3 series provides fully automated zeta potential analysis of macroscopic solids in real-world situations. As electrokinetic analyzers, they use the classic streaming potential and streaming current methods to directly examine the surface zeta potential.

The zeta potential, connected to the surface charge at a solid/liquid interface, is an important metric in understanding surface characteristics and designing new specialized materials.

- SurPASS 3 Standard

- Advanced electrokinetic analyzer for solid surface analysis

- Completely automated zeta potential study of macroscopic solids

- Automated detection of isoelectric points

- Time-dependent measurement of liquid-on-solid adsorption kinetics

- SurPASS 3 Eco

- Entry-level electrokinetic analyzer for routine surface analysis

- Single-point zeta potential results in less than 2 minutes

- Upgrade options for a future-proof investment

Key Features

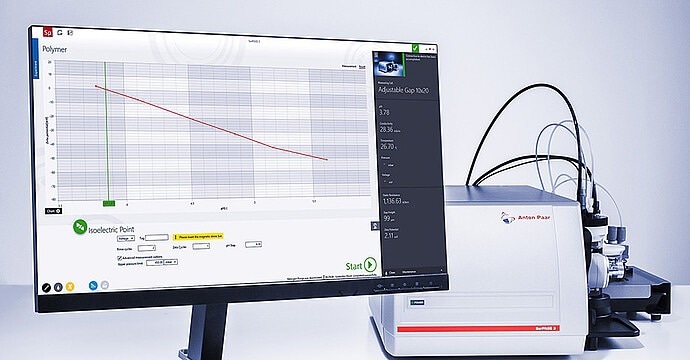

Solid Surface Charge Analysis Made Easy

Image Credit: Anton Paar GmbH

The SurPASS 3 series enables direct investigation of the zeta potential at the solid/liquid interface via streaming potential and current measurement. This allows access to the entire spectrum of zeta potential of technical materials, down to a few millivolts, with unparalleled reliability and repeatability. Gain fast access to surface charge data without complicated evaluation or expert knowledge.

Measuring Solutions from Tiny Particles to Large Wafers

Image Credit: Anton Paar GmbH

The vast range of SurPASS 3 measurement cells covers everything. Elaborate measurement cells can handle materials of any shape, from powders and fibers to planar solids. Sample-specific measuring cells for contact lenses, hollow fiber membranes, flexible tubings, syringes, and vials enable surface charge measurement on complicated geometries.

The “plug-in and start” capability rapidly swaps measuring cells. The software automatically detects the measuring cells and shows the zeta potential.

Fully Automated Measurements in Less Than Two Minutes

Image Credit: Anton Paar GmbH

The user-friendly SurPASS 3 software walks users through the measuring process and displays all essential metrics in real-time. The SurPASS 3 series gives zeta potential data in less than two minutes, allowing maximum sample throughput.

SurPASS 3 automatically enables users to investigate zeta potential's pH dependences and displays the isoelectric point for a thorough understanding of the sample's chemistry. Liquid-on-solid surface adsorption kinetics can be monitored in real time on both model surfaces and actual samples.

Modular Setup Tailored to User’s Needs

Image Credit: Anton Paar GmbH

The SurPASS 3 series is as flexible as the user’s applications. Membrane applications, biomaterials, cosmetics, detergents, and semiconductors all benefit from specialized solutions.

The user has no constraints when dealing with porous or non-porous materials, particles larger than 25 µm, granular materials, fibers, or conductive materials. The device's and measuring cells' modular design enables users to readily expand their zeta potential studies to meet future demands.

Technical Specifications

Source: Anton Paar GmbH

| |

SurPASS 3 |

SurPASS 3 Eco |

| Measuring range |

| Streaming potential |

±2000 mV ± (0.2 % + 4 μV) |

| Streaming current |

±2 mA ± (0.2 % + 1 pA) |

| Cell resistance |

5 Ω to 20 MΩ ± (2 % + 0.5 Ω) |

| Pressure measurement |

3500 mbar ± (0.2 % + 0.5 mbar)

External pressure supply (compressed N₂) is required for differential pressure > 1200 mbar |

1200 mbar ± (0.2 % + 0.5 mbar) |

| pH value |

pH 2 to pH 12 |

| Conductivity |

0.1 mS/m to 1000 mS/m |

| Temperature |

20 °C to 40 °C

Temperature control option is available |

| Sample size requirements |

| Porous films, foils, or plates |

Rectangular-shaped: 20 mm x 10 mm (max. thickness: 2 mm )

Disk-shaped: 14 mm or 15 mm in diameter (max. thickness: 2 mm) |

| Non-porous films, foils, or plates |

Rectangular-shaped: 20 mm x 10 mm (max. thickness: 2 mm) or

min. 35 mm x 15 mm (max. thickness: 40 mm)

Disk-shaped: 14 mm or 15 mm in diameter (max. thickness: 2 mm) or

min. 17 mm in diameter (max. thickness: 40 mm) |

| Particles |

Particle size: min. 25 μm |

| Fibers |

Min. 100 mg |

| Fabrics |

Min. 30 mm x 30 mm |

| Hollow fiber membranes |

Length: min. 170 mm |

| Ceramic membranes |

Flat sheet: 14 mm in diameter

Single channel: outer diameter 10 mm or 13 mm

Multichannel: outer diameter 25 mm or 30 mm |

| Cylindrical cores |

Height: max. 4 inch

Diameter: 1 inch |

| Flexible tubing |

Length: min. 100 mm

Outer diameter: 0.7 mm to 6 mm |

| Pre-filled syringes |

Syringe barrel “1.0 mL long” (ISO 11040-4) |

| Vials |

2R/4R vials (ISO format), outer diameter 16 mm |

| Technical requirements |

| Mains supply |

AC 115 to 230 V, 50 to 60 Hz, 200 VA |

| Dimensions |

600 mm x 432 mm x 245 mm (D x W x H)

Footprint: 612 mm x 536 mm (D x W)

Clearance: 360 mm |

| Weight |

26 kg |

24 kg |

| Software requirements |

- Microsoft Windows® 7 32/64 bit with SP1 or later is required. Windows 7 Starter is not supported. Microsoft Windows® 8 32/64 bit Microsoft Windows® Server 2008/2008 R2 32/64 bit with Service Pack 2 or higher is required for Windows Server 2008 Microsoft Windows® 10 32/64 bit

- Intel® Core™ i3 CPU

- 4 GB RAM (depends on operating system)

- 20 GB free disk space

- 1 free USB port

- Screen resolution of at least 1024 x 768 at True Color (32 bit)

|