For industrial applications with high demands on dynamics and precision, the X-417 multi-axis system provides an integrated solution. Systems from XY or XYZ with the appropriate ACS high-performance controller from PI are available. The system comprises two V-417 high-load linear stages with linear motors and absolute-measuring linear encoders.

Combining different travel range variants is possible: 204 mm to 407 mm. Granite plates are also offered for the XY systems. For the XYZ systems, the Z axis is an L-412 high-load linear stage with a 102 mm travel range, synchronous servo motor, and holding brake.

The adapter bracket needed to secure the Z axis to the granite base is part of the delivery for the XYZ systems that also come with a granite plate as a base.

Features

- Optional with granite base plate

- Delivery includes extensive test reports

- Extensive accessories and software support are available

- XY system is made of two V-417 positioners, with travel ranges from 204 to 407 mm

- XYZ system with L-412 positioner as Z axis, 102 mm travel range

- Suitable G-901 ACS controller with ACS driver module

X-417.0xx: XY system with G-901 2-axis controller. Image Credit: PI (Physik Instrumente) LP

X-417.1xx: XY system on granite plate (image without controller). Image Credit: PI (Physik Instrumente) LP

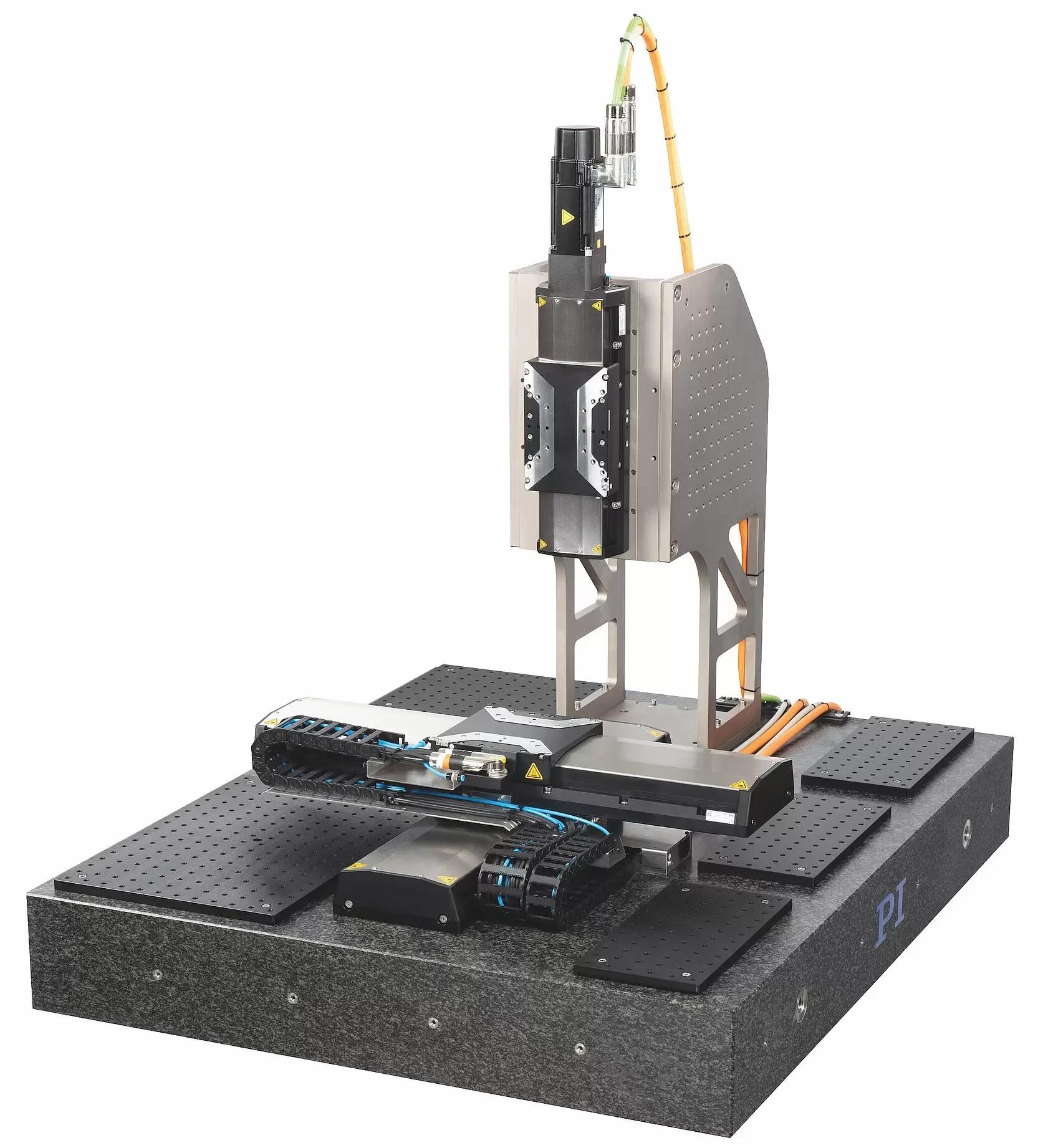

X-417.2xx with accessories: XYZ system on granite plate (image without controller); X-417.Z02 breadboard set. Image Credit: PI (Physik Instrumente) LP

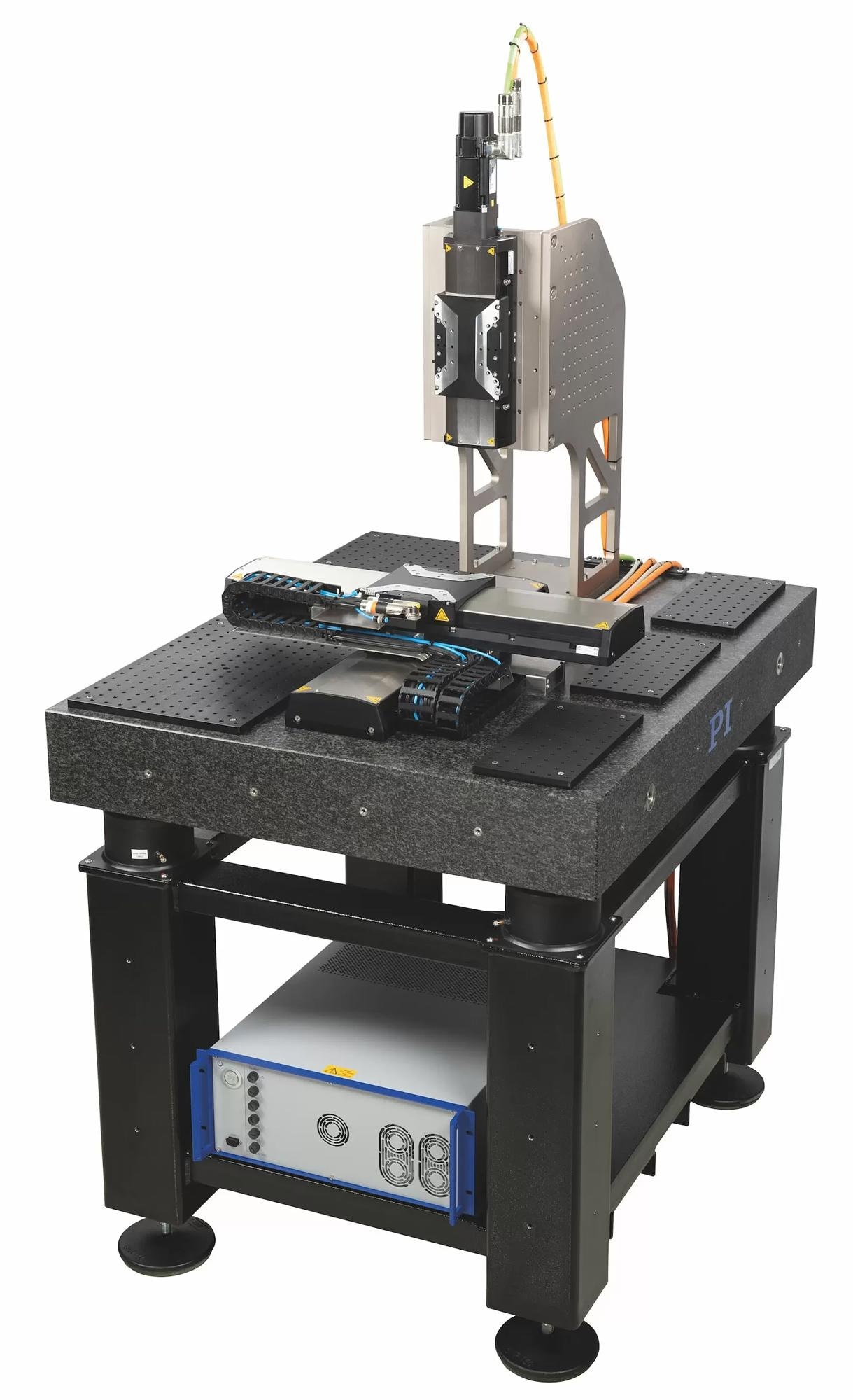

X-417.2xx with accessories: XYZ system on a granite plate, G-901 3-axis controller; X-417.Z02 breadboard set, X-417.Z01 base frame. Image Credit: PI (Physik Instrumente) LP

Cable Management

All systems are delivered with a suitable cable set. Each axis drive cable in the cable set is 5 m long. A shorter cable set of 2 m is available as an accessory if shorter cables are necessary, such as when putting the controller in the base frame.

Application Fields

Laser Machining

Electronics production; Ultrashort pulse laser machining; Laser micromachining; Galvo integration; Laser ablation; Test and inspection; Ceramics and diamond cutting; Laser drilling; Laser welding.

Options and Accessories

- Additional cable set for XYZ system: Cable length for X/Y axes 2 m, for Z axis 3 m

- Software support, e.g. for SPS integration

- Base frame

- Breadboard set for granite plate

- Adapter bracket

Specifications

Source: PI (Physik Instrumente) LP

| General |

X-417.0xx |

X-417.1xx |

X-417.2xx |

X-417.3xx |

Unit |

|

Active axes

|

2

|

2

|

3

|

3

|

|

|

Controller

|

G-901.R519

|

G-901.R519

|

G-901.R5197

|

G-901.R5197

|

|

|

Granite base

|

–

|

1100 mm × 900 mm × 150 mm

|

1100 mm × 900 mm × 150 mm

|

–

|

|

|

Cable length

|

5

|

5

|

5

|

5

|

m

|

|

Max. workpiece size on XY system

|

–

|

–

|

300 mm × 300 mm × 100 mm

|

300 mm × 300 mm × 100 mm

|

|

|

Operating temperature range

|

5 to 40

|

5 to 40

|

5 to 40

|

5 to 40

|

°C

|

|

Humidity

|

Max. 80% rel., not condensing

|

Max. 80% rel., not condensing

|

Max. 80% rel., not condensing

|

Max. 80% rel., not condensing

|

|

X axis: Lower positioner, Y axis: Upper positioner

| Motion |

X-417.x22 |

X-417.x32 |

X-417.x33 |

X-417.x42 |

X-417.x43 |

X-417.x44 |

Unit |

|

Travel range (XY)

|

204 × 204

|

305 × 204

|

305 × 305

|

407 × 204

|

407 × 305

|

407 × 407

|

mm

|

|

1-D positioning accuracy (X / Y)(1)

|

±1.5 / ±1.5

|

±1.5 / ±1.5

|

±1.5 / ±1.5

|

±1.5 / ±1.5

|

±1.5 / ±1.5

|

±1.5 / ±1.5

|

µm

|

|

XY orthogonality

|

30

|

30

|

25

|

25

|

20

|

20

|

µrad

|

|

Max. velocity (X / Y)(2)

|

1.5 / 2.0

|

1.5 / 2.0

|

1.5 / 2.0

|

1.5 / 2.0

|

1.5 / 2.0

|

1.5 / 2.0

|

m/s

|

| Encoder options |

X-417.xxx |

Unit |

|

Integrated sensor

|

Absolute-measuring linear encoder

|

|

|

Sensor signal

|

EnDat 2.2

|

|

|

Design resolution

|

0.001

|

µm

|

|

Minimum incremental motion

|

10

|

nm

|

|

Limit switch

|

–

|

|

| Mechanical properties |

X-417.x22 |

X-417.x32 |

X-417.x33 |

X-417.x42 |

X-417.x43 |

X-417.x44 |

Unit |

|

Max. payload

|

15

|

15

|

15

|

15

|

15

|

15

|

kg

|

|

Mass (XY system)(3)

|

22

|

24

|

26

|

26

|

28

|

30

|

kg(4)

|

|

Mass (XYZ system, incl. granite base and adapter bracket)(3)

|

481

|

483

|

484

|

484

|

486

|

488

|

kg(4)

|

| Z axis: L-412.059054B |

in X-417.2xx |

Unit |

|

Travel range

|

102

|

mm

|

|

Positioning accuracy, uncalibrated (max.)

|

±6

|

µm

|

|

Minimum incremental motion

|

2

|

µm

|

|

Bidirectional repeatability (max.)

|

±3

|

µm

|

|

Velocity, unloaded (max.)

|

300

|

mm/s

|

|

Max. payload

|

15

|

kg

|

|

Holding brake(5)

|

Electromagnetic safety brake

|

|

| Granite base |

in X-417.1xx and X-417.2xx |

Unit |

|

Flatness

|

5

|

µm

|

|

Mass

|

430

|

kg(4)

|

(1) Based on a measuring height of approx. 30 mm above the platform. Recommended ambient conditions for 1-D positioning accuracy: 21 °C ± 1 °C at 50 to 60 % relative humidity

(2) Values depend on application-specific parameters. For detailed information, contact PI.

(3) Without cable management

(4) ± 5 %

(5) Safety coefficients for the holding brake are available on request