Mar 1 2010

Vacuum panels are particularly good for insulating buildings - as long as the vacuum does not leak. A tiny pressure sensor constantly checks the condition of the vacuum and indicates whether the insulation effect is still present.

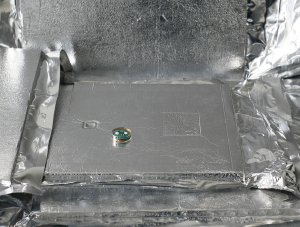

A pressure sensor inside the vacuum insulation panel constantly checks whether the vacuum is still present. (© Fraunhofer IMS)

A pressure sensor inside the vacuum insulation panel constantly checks whether the vacuum is still present. (© Fraunhofer IMS)

Mrs Miller is happy. Since she moved to the new apartment building she has not had any nasty surprises on her heating bills. This is because the building is insulated with a new material which exhibits particularly low thermal conductivity and therefore high energy efficiency. Vacuum insulation panels consist of a tightly sealed shell and porous core material made of silicic acid. This serves to support the vacuum in the insulation panel. Because a vacuum is a very good thermal insulator, the insulation value of the vacuum panels is five to ten times higher than that of conventional panels, for instance those made of polystyrene.

The panels are sensitive, however. Over the years the airtight film loses its insulating effect and the vacuum leaks. Experts put the increase in gas pressure at 1 millibar per year. Another problem is that because the film is very thin it can be damaged during transport. Before being installed the panels therefore have to be checked to see whether the vacuum and insulating effect are still present. So that the condition of the panels can be determined at any time, research scientists at the Fraunhofer Institute for Microelectronic Circuits and Systems IMS in Duisburg have developed a tiny pressure sensor. "The pressure sensor is placed in a recess inside the panel. On the board next to the microchip there is a transponder with a coil which transmits the measured data through the film without any hard wire connection. A reader on the outer wall of the panel receives the measured data and supplies the transponder with energy using a second coil," explains Dr. Hoc Khiem Trieu, head of department at the IMS. "The sensor consumes very little energy and is extremely small, measuring only around 20 square millimeters. A further special feature of the tiny sensor is that it draws its energy from the reader’s radio signal even through thin metal layers. It is therefore also suitable for measuring the vacuum in refrigerators, where low thermal conductivity is likewise essential."

The sensor is used in the medical field, for instance to measure blood or eye pressure. It has now been developed further for the construction sector. "The sensor is presently at the prototype stage. The aim is to put it into series production in one to two years’ time," states Trieu. The IMS will be showcasing the sensor at Euro ID, the trade fair for automatic identification, in Cologne from May 4 to 6 (Stand A12).